Robot self-propelled chassis

A self-propelled, robotic technology, used in motor vehicles, vehicle maintenance, lifting vehicle accessories, etc., to achieve the effect of enhancing stability and ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0043] Robotic self-propelled chassis, used in conjunction with the robot. In the embodiment of the present invention, the self-propelled chassis of the robot is used in conjunction with the handling robot in the train compartment for loading, unloading and stacking bagged materials.

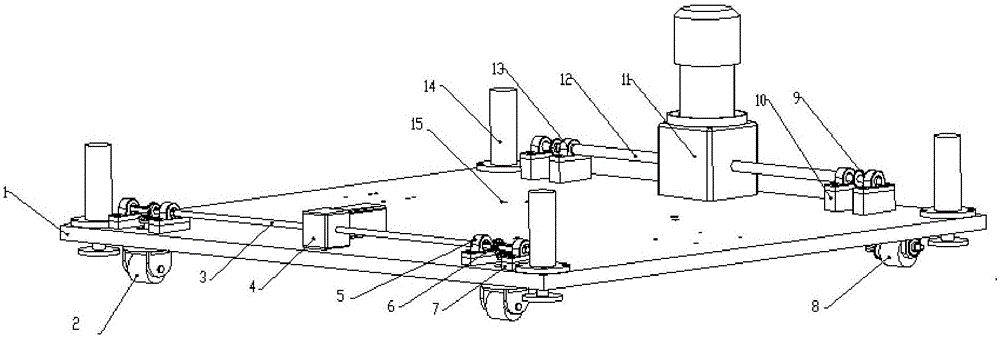

[0044] like figure 1 As shown, the robot self-propelled chassis includes: chassis 1, connecting mechanism 15, front axle steering system, rear axle drive system and hydraulic lifting system.

[0045] The connection mechanism 15 is arranged on the chassis 1 , and the handling robot is connected to the chassis 1 through the connection mechanism 15 .

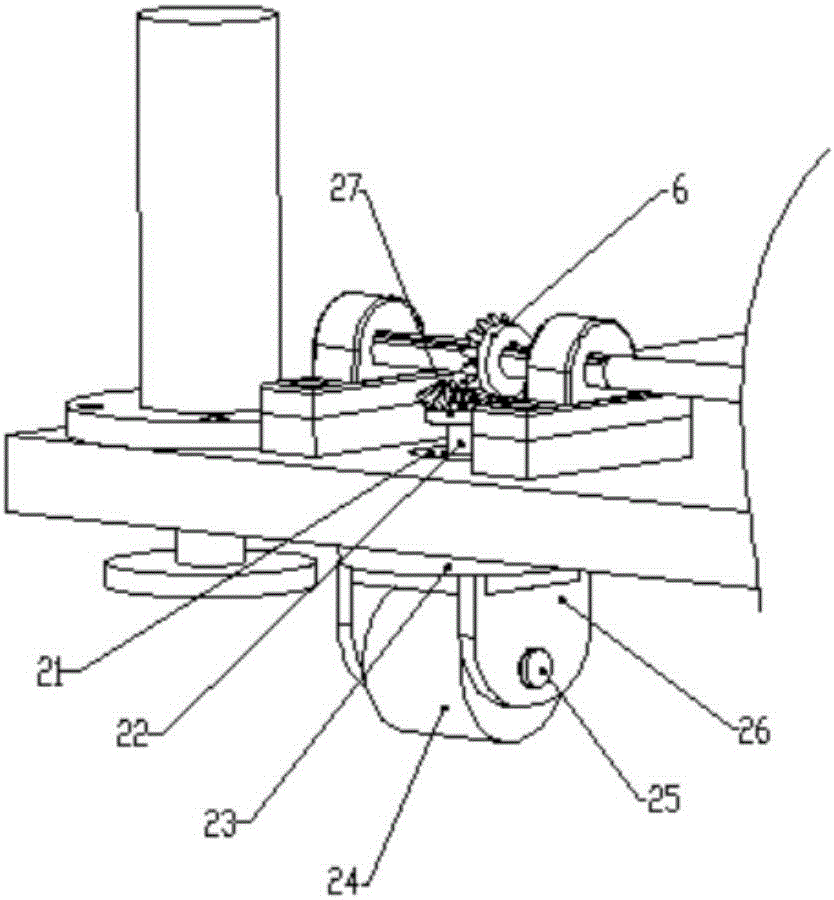

[0046] The front axle steering system is arranged at the front of the chassis 1, and the front axle steering system includes a steering stepper motor-reducer group 4, a front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com