Composite stained soft glass and preparation method thereof

A soft glass, color painting technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of finished product odor generation and high VOC volatile organic compound content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of laminated colored painted soft glass, comprising the following steps:

[0031] Step 1: Calendering molding, the PVC main material, plasticizer, stabilizer, accelerator and colorant are passed through a metering device, a high-speed stirring device, a cooling and stirring device, an internal mixer, and a calendering device to obtain a calendered film;

[0032] Step 2: washing and drying, the calendered film is washed with clean water at a temperature of 20-30°C, and then dried on a heating roller at a drying temperature of 120-130°C;

[0033] Step 3: cooling, using five rollers for cooling, the temperatures of the five cooling rollers are respectively 120-150°C, 120-150°C, 120-150°C; 100-120°C, 90-110°C;

[0034] Step 4: coiling and packaging, coiling and packaging the cooled film to obtain a PVC film coil;

[0035] Step 5: let stand, let the PVC film roll stand for 24 to 48 hours at room temperature, and the room temperature is 20 to 30 °C;

[...

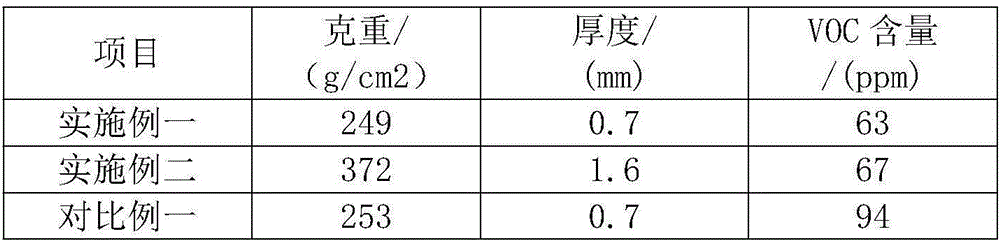

Embodiment 1

[0047] A preparation method of colored painted soft glass, the specific steps are as follows:

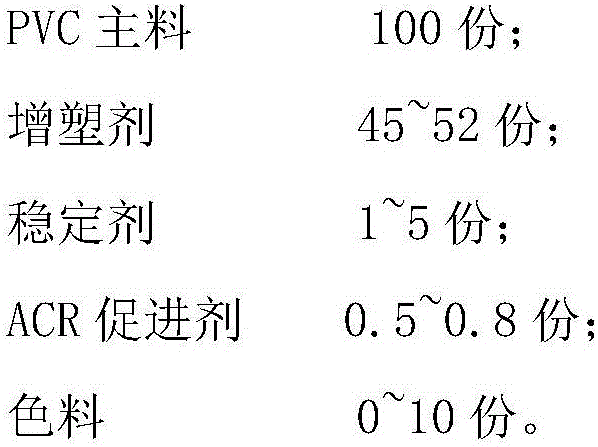

[0048] Step 1: Preparation of raw materials, the raw material formula consists of 100 parts of PVC, 50 parts of plasticizer, 2 parts of stabilizer, 0.6 part of ACR accelerator, and 5 parts of colorant; Dioctyl phthalate, the stabilizer is a mixture of calcium zinc soap and triphenyl phosphite, and the mass ratio of the two is 1:1.

[0049] Step 2: high-speed mixing, each raw material component is measured by a metering device, and then mixed and stirred by a high-speed mixing device, and the temperature of high-speed stirring is controlled at 100 ° C;

[0050] Step 3: cooling and stirring, the uniformly mixed composition is stirred by a cooling and stirring device, and the stirring temperature is controlled at 45°C;

[0051] Step 4: Banburying, the composition after cooling and stirring is banburying through an internal mixer, and the banburying temperature is controlled at 160-170...

Embodiment 2

[0059] A preparation method of colored painted soft glass, the specific steps are as follows:

[0060] Step 1: Preparation of raw materials, the raw material formula includes 100 parts of PVC, 48 parts of plasticizer, 3 parts of stabilizer, 0.7 parts of ACR accelerator, and 8 parts of colorant according to mass; Dioctyl phthalate, the stabilizer is a mixture of calcium zinc soap and triphenyl phosphite, and the mass ratio of the two is 1:0.7.

[0061] Step 2: high-speed mixing, each raw material component is measured by a metering device, and then mixed and stirred by a high-speed mixing device, and the temperature of high-speed stirring is controlled at 105 ° C;

[0062] Step 3: cooling and stirring, the uniformly mixed composition is stirred by a cooling and stirring device, and the stirring temperature is controlled at 40-50 °C;

[0063] Step 4: Banburying, the composition after cooling and stirring is banburying through an internal mixer, and the banburying temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com