Device for edge-cutting coconut fiber board

A technology of coconut palm board and edge trimming, which is applied to other plywood/plywood appliances, metal processing, wood processing appliances, etc., can solve the problems that affect the quality of coconut palm board, and the coconut palm silk is not easy to cut, so as to achieve crisp cutting and improve the efficiency of cutting. The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

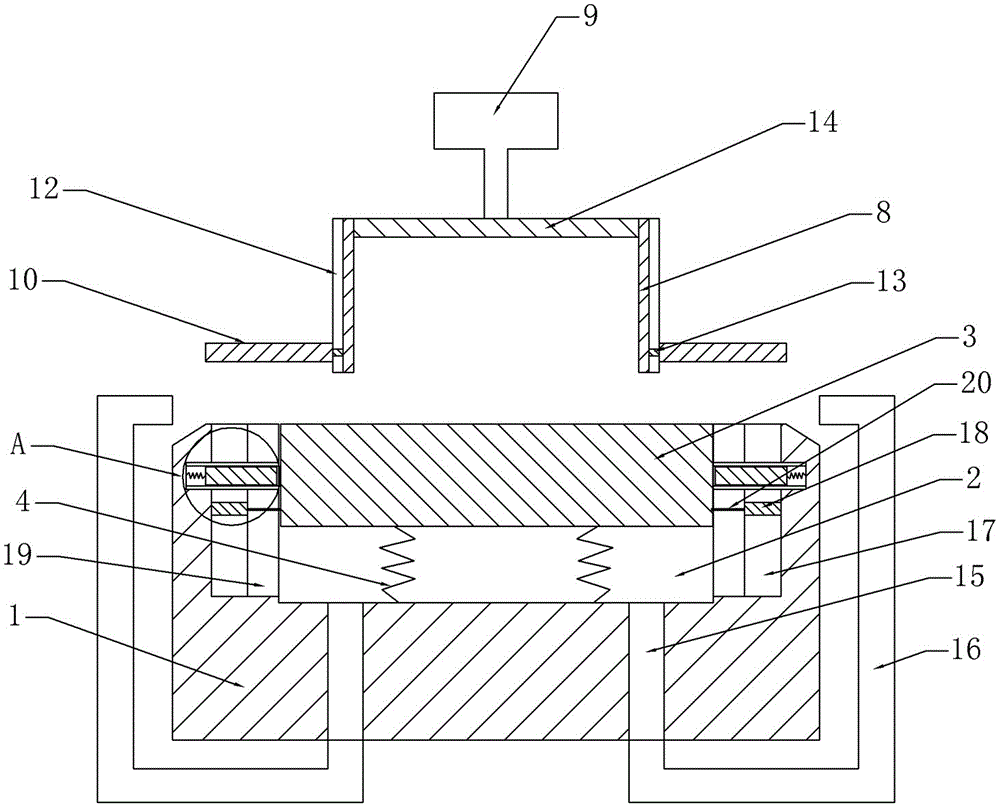

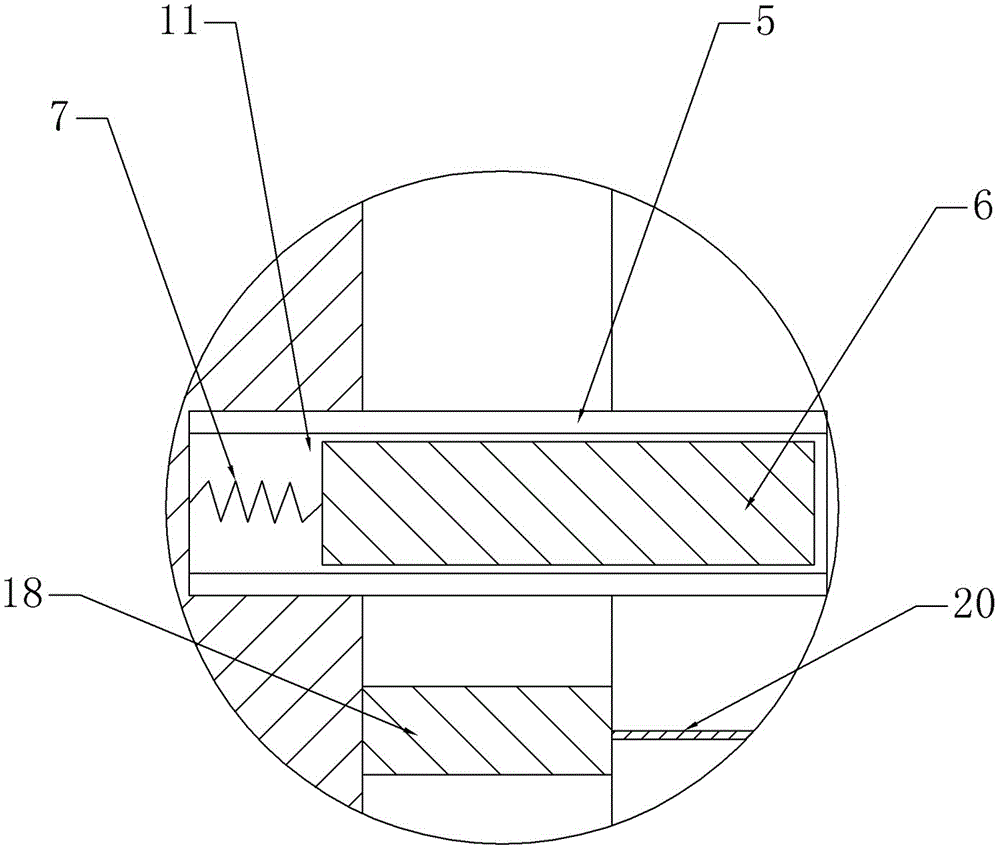

[0021] The reference signs in the drawings of the description include: storage table 1, forming groove 2, platform 3, first spring 4, first groove 5, shredding knife 6, second spring 7, edge cutting knife 8, hydraulic press 9, Positioning plate 10, first chute 11, second chute 12, slider 13, force plate 14, through hole 15, air pipe 16, second groove 17, pressure plate 18, slideway 19, connecting rod 20.

[0022] This example figure 1 and figure 2 Shown, the device that is used for the edge trimming of coconut palm board comprises the storage platform 1 that is arranged horizontally, and the edge of storage platform 1 is provided with the inclined-plane that inclines downwards. The upper end of the storage table 1 is provided with a cuboid forming groove 2, and a platform 3 arranged horizontally is arranged in the forming groove 2, and the platform 3 cooperates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com