A structurally optimized meal delivery robot base

A food delivery robot and bottom plate technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of spilled dishes, low chassis, high stability requirements of food delivery robots, etc., to achieve the effect of improving stability and reducing bumps and shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

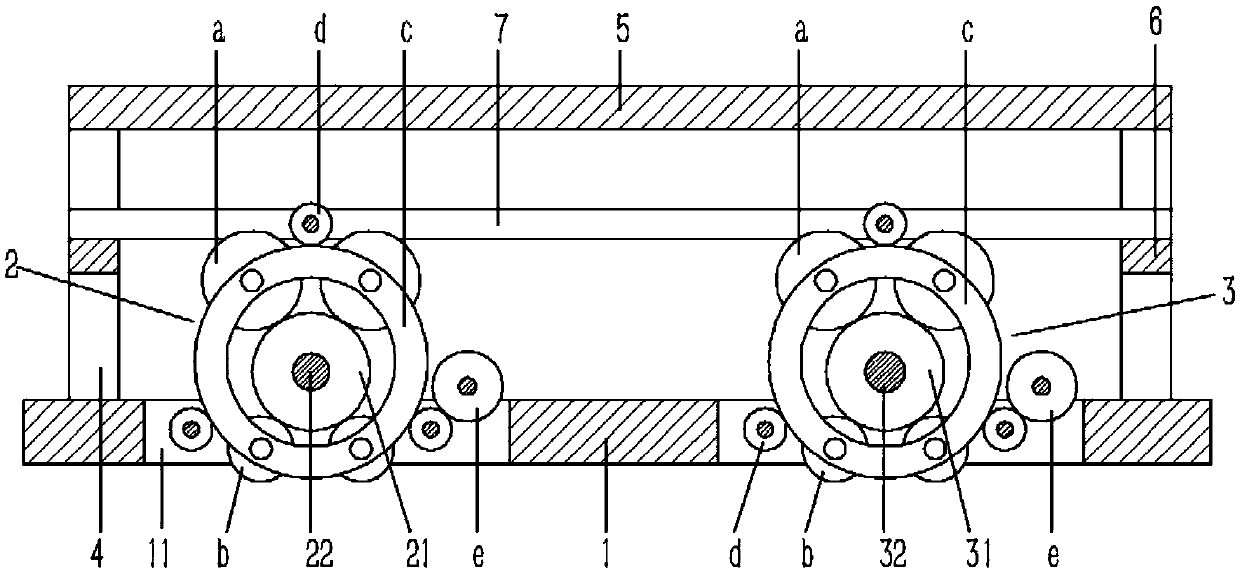

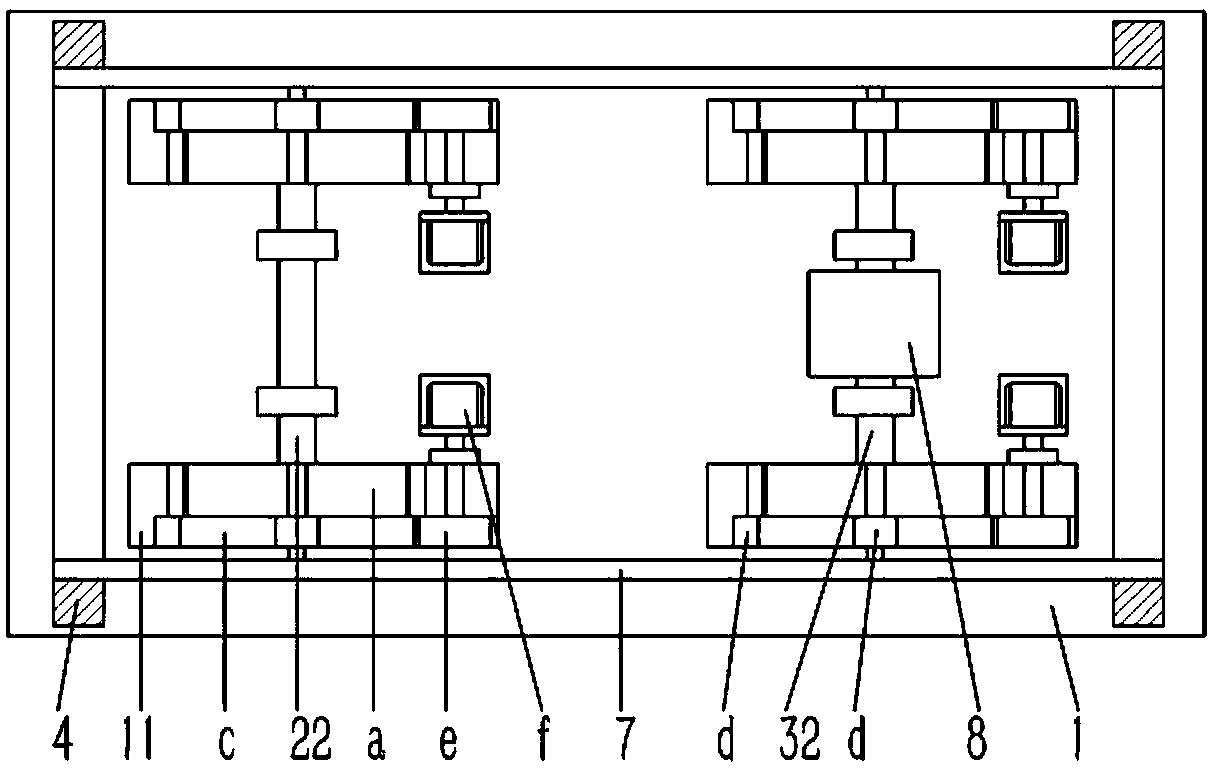

[0017] Example: see figure 1 , 2 As shown, a structure-optimized meal delivery robot base includes a rectangular bottom plate 1, a number of slots 11 are respectively formed on the front and rear sides of the bottom plate 1, and the slots 11 on the front and rear sides of the bottom plate 1 are inserted respectively. There are a front guide wheel assembly 2 and a rear drive wheel assembly 3, the front guide wheel assembly 2 includes a guide wheel 21, the guide wheel 21 is hinged on the two ends 22 of the guide shaft 22, and the guide shaft 22 is fixed in the slot hole on the front side of the bottom plate 1 through a bearing seat On the bottom plate 1 between 11, the two sides of the upper end of the guide wheel 21 respectively abut against the upper roller a, and the two sides of the lower end of the guide wheel 21 respectively abut against the lower roller b, the lower roller b and the upper roller a are hinged on the gear On the ring c, the periphery of the ring gear c is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com