Automatic feeding device and diamond cutter head bottom surface grinding machine

A diamond cutter head, automatic feeding technology, applied in the direction of grinding workpiece supports, metal processing equipment, parts of boring machines/drilling machines, etc. knife face etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

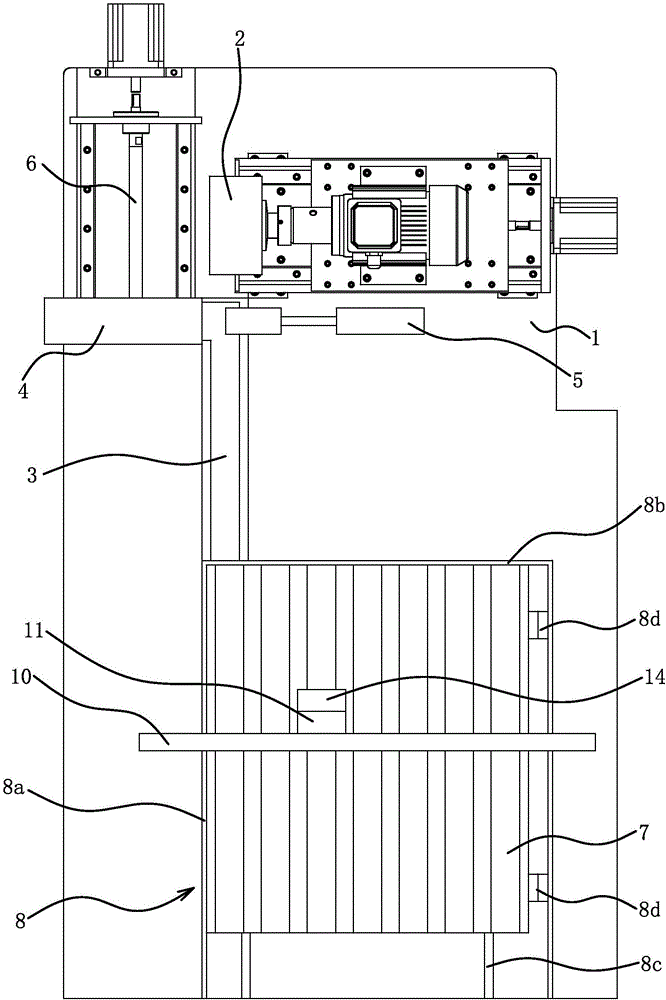

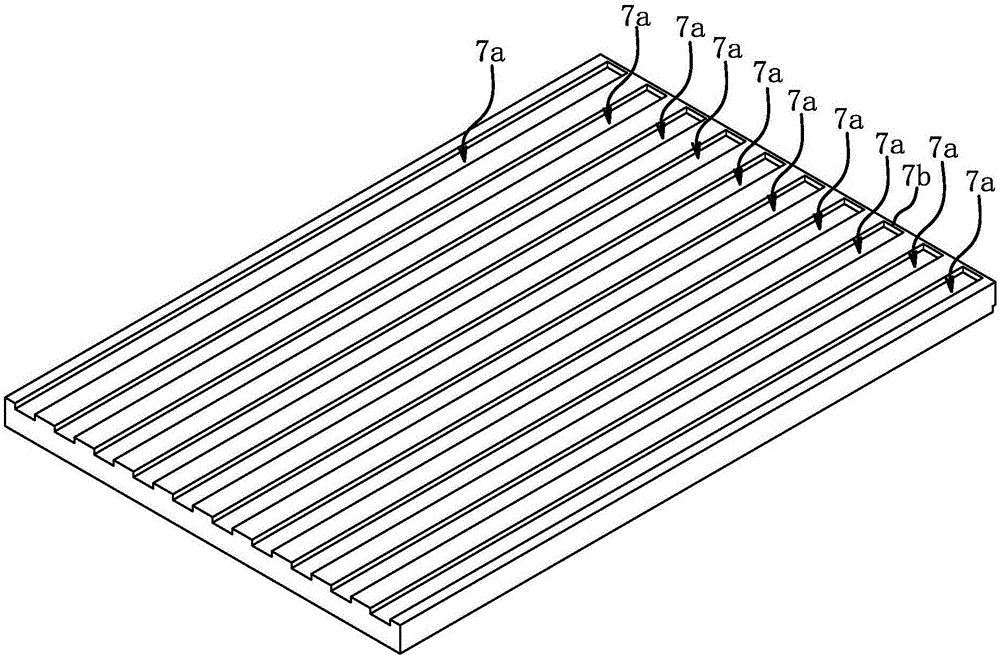

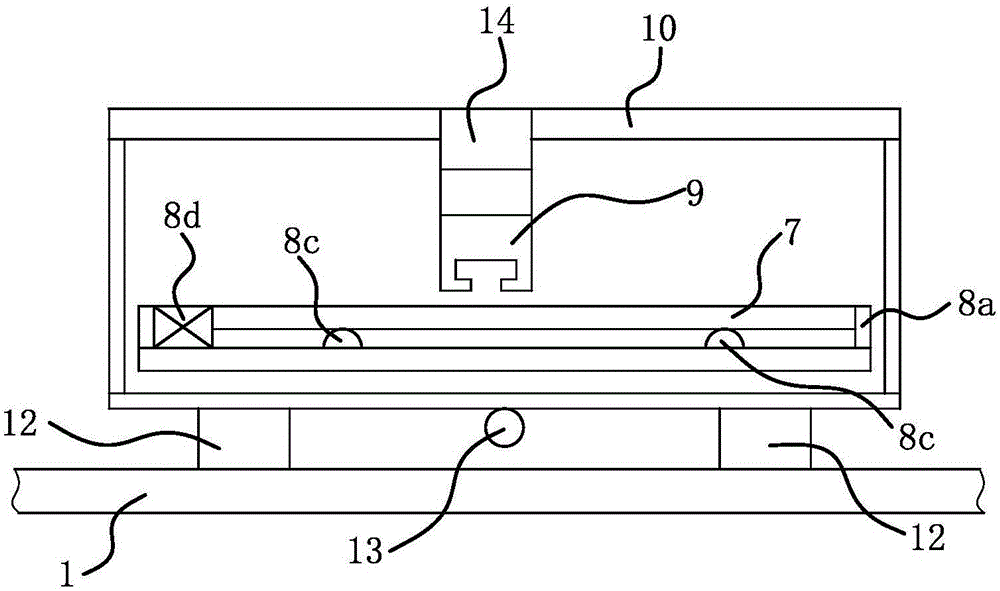

[0018] Such as figure 1 with figure 2 As shown, the bottom surface grinding machine of the diamond segment comprises a frame 1, a grinding wheel 2, a segment feeding device and an automatic feeding device.

[0019] The grinding wheel 2 is connected to the frame 1 through the authorized notification number CN203293025U of the grinding wheel position adjustment system. The authorized notification number CN203292956U of the cutting head feeding device includes the cutting head transfer part 3, the cutting head clamp 4, the pushing mechanism 5 and the feeding mechanism 6;

[0020] The automatic feeding device can automatically deliver the diamond segment 15 to the conveyor belt and the orientation of the diamond segment 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com