Electric power tower base welding system and welding method thereof

A welding system and electric tower technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult to meet the welding requirements of high-quality products, difficult to guarantee welding quality, and mutual interference of arcs, so as to reduce labor force Strength, guaranteed welding quality, effect of guaranteed welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

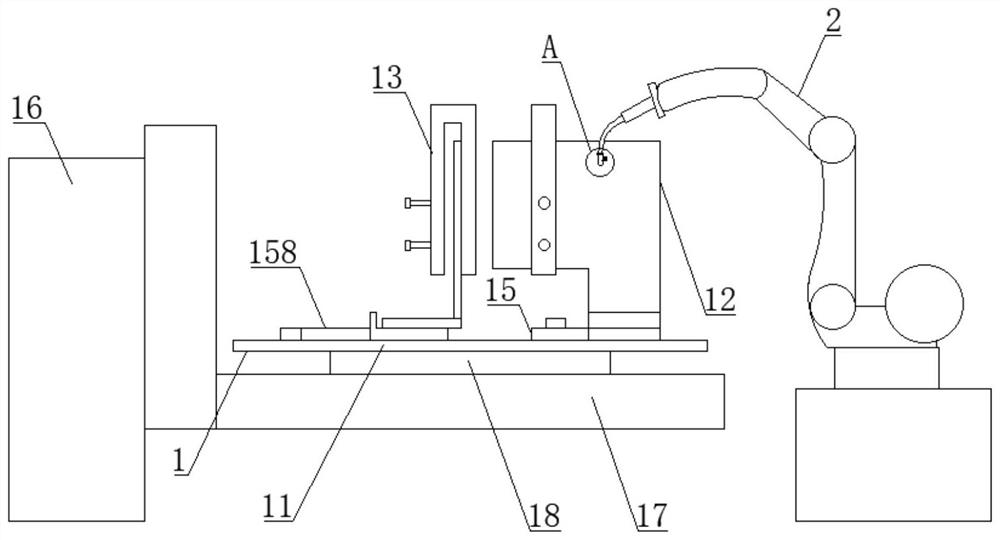

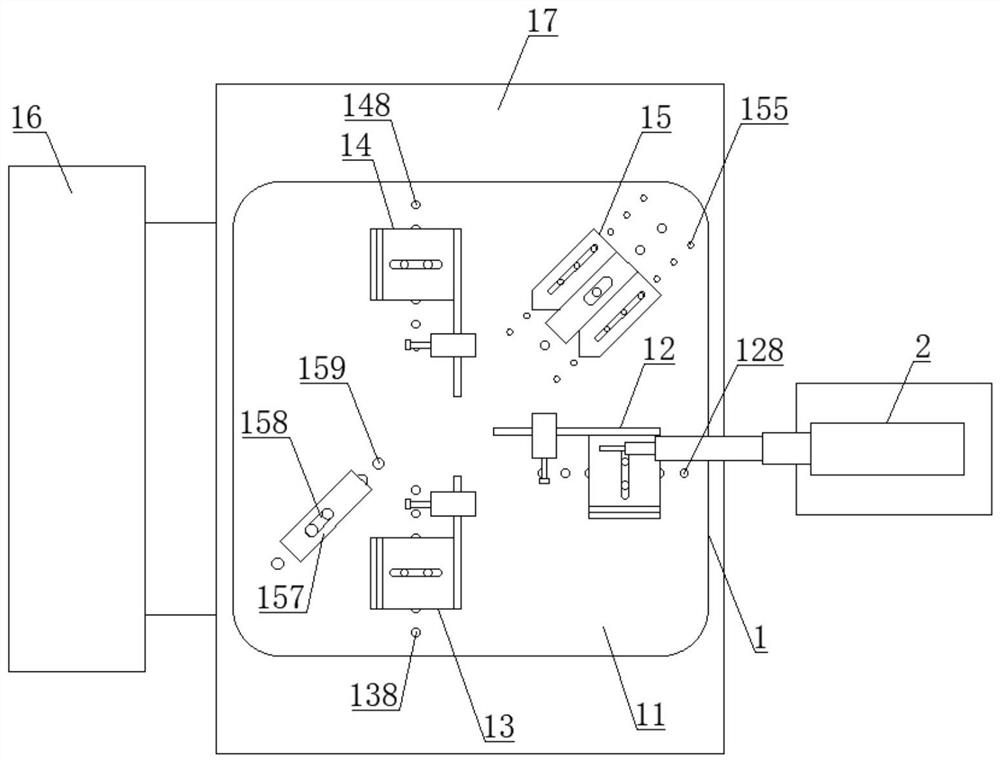

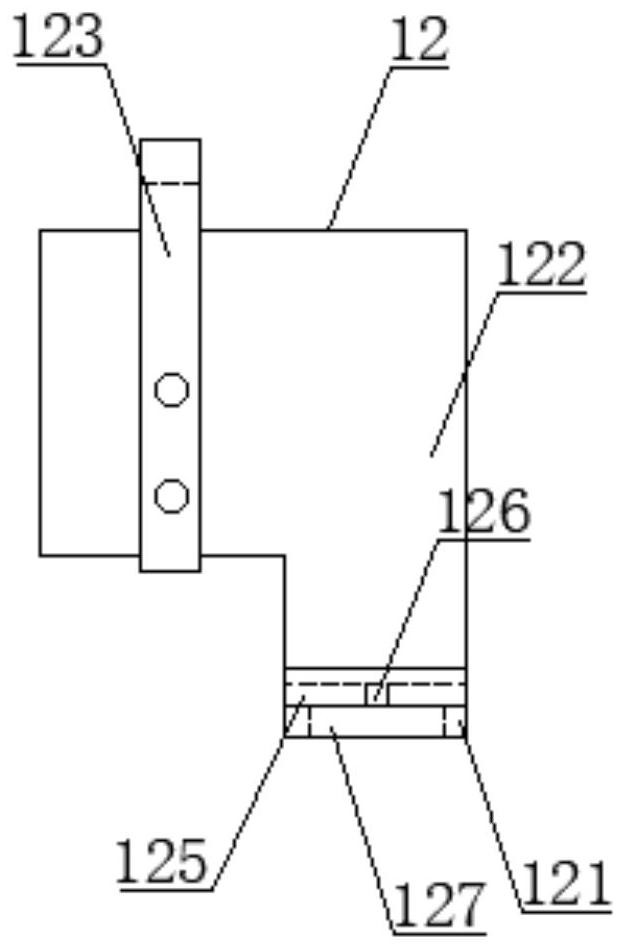

[0047] A kind of welding system of electric power tower base, such as Figure 1-11 As shown, it includes a welding tool 1 and a welding robot 2. The welding tool 1 includes a tooling base plate 11. A first fixing component 12 is arranged on the tooling base plate 11. A second fixing component 13 and a third fixing component 13 are respectively arranged on one side of the first fixing component 12. The fixed assembly 14; the first fixed assembly 12 includes a first fixed plate 121, the first fixed plate 121 is provided with a first support plate 122, the first support plate 122 is provided with a first splint 123; the first splint 123 is provided with The first U-shaped groove 124 whose thickness is greater than the thickness of the first support plate 122; The second clamping plate 133; the second clamping plate 133 is provided with a second U-shaped groove 134 whose thickness is greater than that of the second support plate 132; the third fixing assembly 14 includes a third f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com