Detoxifying method of dioxin and heavy metal in waste incineration fly ash

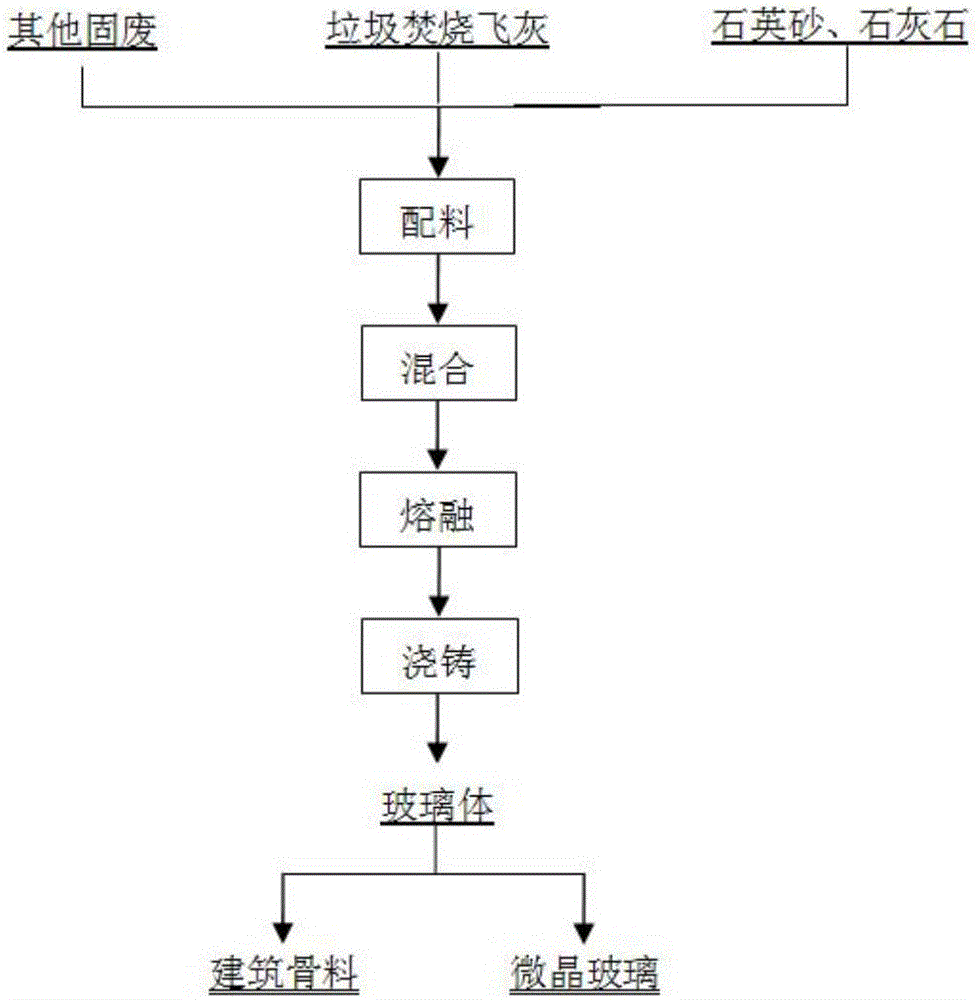

A technology for waste incineration fly ash and heavy metals, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve dioxin and heavy metal pollution, cannot solve dioxin pollution problem, cannot eliminate dioxin pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mix the waste incineration fly ash, waste incineration bottom ash, pickling sludge and quartz sand evenly, and the contents (wt.%) of the incineration fly ash, waste incineration bottom ash, pickling sludge and quartz sand in the mixture are 5% respectively. , 5%, 30% and 60%, (CaO+MgO):(SiO 2 +Al 2 O 3 ) molar ratio of 0.1. The mixture was heated to 1450°C and melted to obtain a melt, which was cooled to obtain a glass body. Using high temperature pyrolysis to detoxify dioxin and alkali oxides (CaO+MgO) in the mixture to solidify chlorine element, the concentration of dioxin in the exhaust gas is 0.1TEQng / m 3 , much lower than the GB31574-2015 limit (0.5TEQng / m 3 ). Utilize SiO in solid waste 2 and Al 2 O 3 As the heavy metals in the network solidification, the leaching concentration of Cr is 0.13 mg / L, the leaching concentration of Pb is 0.11 mg / L, the leaching concentration of Cd is 0.12 mg / L, the leaching concentration of Ni is 0.12 mg / L, and the leaching co...

Embodiment 2

[0029] Mix the waste incineration fly ash and quartz sand evenly, the contents (wt.%) of the waste incineration fly ash and quartz sand in the mixture are 80% and 20% respectively, (CaO+MgO):(SiO 2 +Al 2 O 3 ) molar ratio of 1.0. The mixture was heated to 1350°C and melted to obtain a melt, which was cooled to obtain a glass body. Utilize pyrolysis to detoxify dioxins and the alkaline oxides (CaO+MgO) in the mixture to solidify chlorine element, and the concentration of dioxins in the exhaust gas is 0.4TEQng / m 3 , much lower than the GB31574-2015 limit (0.5TEQng / m 3 ). Utilize SiO in solid waste 2 and Al 2 O 3 As the heavy metals in the network solidification, the leaching concentration of Cr is 0.20 mg / L, the leaching concentration of Pb is 0.15 mg / L, the leaching concentration of Cd is 0.15 mg / L, the leaching concentration of Ni is 0.22 mg / L, and the leaching concentration of Zn is 0.15 mg. / L, Cu leaching concentration is 0.25mg / L, the leaching rate of heavy metals ...

Embodiment 3

[0031] Mix the waste incineration fly ash, the waste incineration bottom ash and the quartz sand evenly. +MgO):(SiO 2 +Al 2 O 3) molar ratio of 1.1. The mixture was heated to 1400°C and melted to obtain a melt, which was cooled to obtain a glass body. Using high temperature pyrolysis to detoxify dioxin and alkali oxides (CaO+MgO) in the mixture to solidify chlorine element, the concentration of dioxin in the exhaust gas is 0.09TEQng / m 3 , much lower than the GB31574-2015 limit (0.5TEQng / m 3 ). Utilize SiO in solid waste 2 and Al 2 O 3 As the heavy metals in the network solidification, the leaching concentration of Cr is 0.06 mg / L, the leaching concentration of Pb is 0.24 mg / L, the leaching concentration of Cd is 0.21 mg / L, the leaching concentration of Ni is 0.12 mg / L, and the leaching concentration of Zn is 0.40 mg. / L, Cu leaching concentration is 0.20mg / L, the leaching rate of heavy metals is lower than the specified value of GB5085.3-2007.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com