Method for producing insect proteins and grease by efficient conversion of crop straws through multi-stage cooperation of insects

A technology of crop straw and insect protein is applied in the field of biotechnology to achieve cost-saving, high-efficiency and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

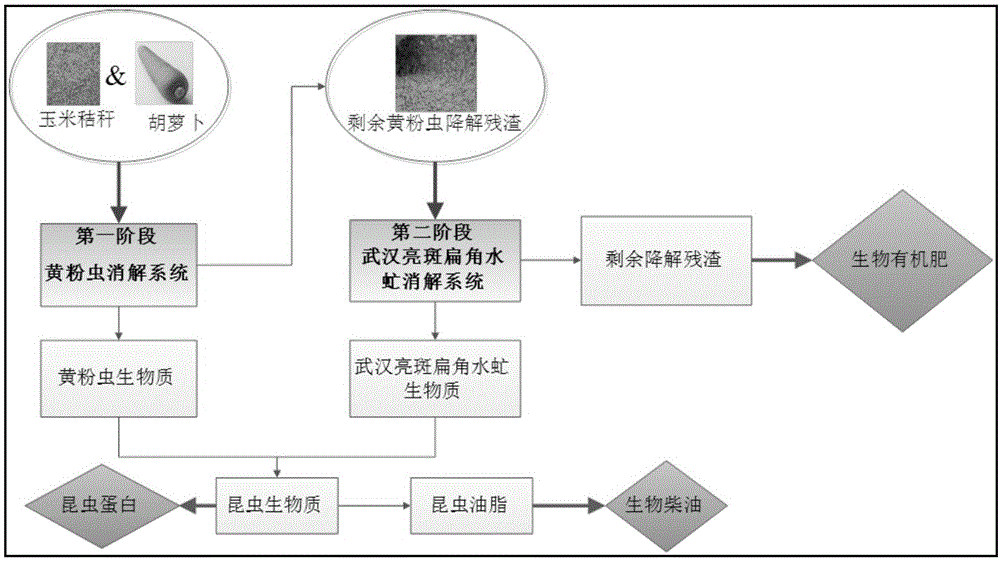

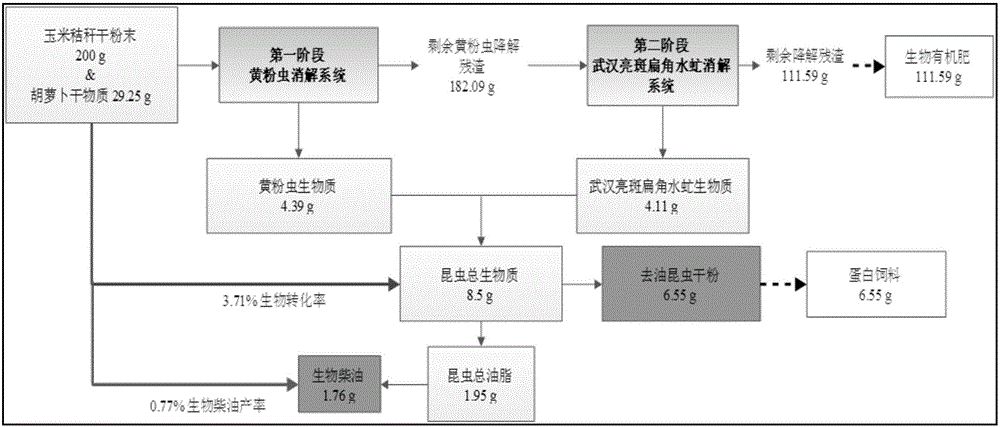

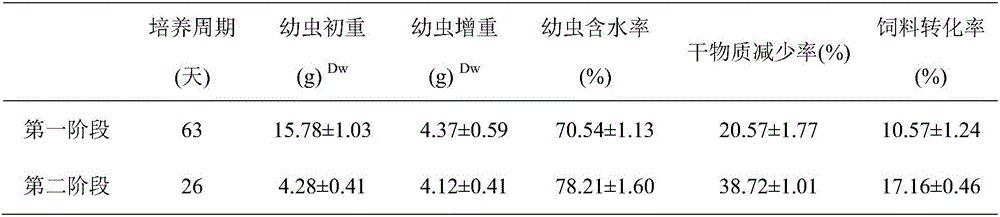

Method used

Image

Examples

Embodiment 1

[0034] The method for producing insect protein and oil by utilizing insect multi-stage combined high-efficiency transformation of crop straw, comprising the following steps:

[0035] 1. Pretreatment of materials:

[0036] Preliminarily crush the corn stalks, then put them into a constant temperature electric oven at 60°C to dry for 6 days, and then pulverize the dried corn stalks with a pulverizer until all the stalk powder passes through a 20-mesh separation sieve, and the obtained The corn stalk powder was kept dry and stored in a constant temperature electric oven at 60°C until the next step.

[0037]2. Take 200 g of dry corn stalk powder, put it in a clean washbasin prepared in advance, and add 1700 52-day-old Tenebrio larvae to it. Moisture for the growth of the mealworms is provided by adding fresh carrot slices to the basin. The frequency of adding carrots was once every 2 days, and the amount of each addition was 13 g, and the addition was stopped 2 days before the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com