Rose-flavored seabuckthorn fruit cake and preparation method thereof

A technology of seabuckthorn fruit and rosehip, which is applied in confectionery, confectionary industry, food science, etc., can solve the problems of loss of nutrients in seabuckthorn fruit, and achieve the effect of preventing the loss of nutrients, outstanding flavor and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A kind of preparation method of sea-buckthorn rosehip cake provided by the embodiment of the present invention comprises the following steps:

[0018] S1 prepares materials according to the following parts by weight:

[0019] 5-50 parts of seabuckthorn fruit; 1-10 parts of rose; 1-2 parts of gelling agent; 40-70 parts of sweet substance; 0.4-0.7 part of sour agent and 0.03-0.06 part of food preservative.

[0020] Seabuckthorn fruit can be fresh sea buckthorn fruit or dried sea buckthorn fruit, and rose can be fresh rose or dried rose flower. It should be noted that, when selecting seabuckthorn fruit and roses by weight, the parts by weight of dried seabuckthorn fruit and dried roses are smaller than that of fresh seabuckthorn fruit and fresh roses. For example, 5-7 parts of dried seabuckthorn fruit, 1-2 parts of dried rose; 20-50 parts of fresh sea-buckthorn fruit, 5-10 parts of fresh rose.

[0021] Rose petals are rich in vitamin C, mild in nature, nourishing yin and...

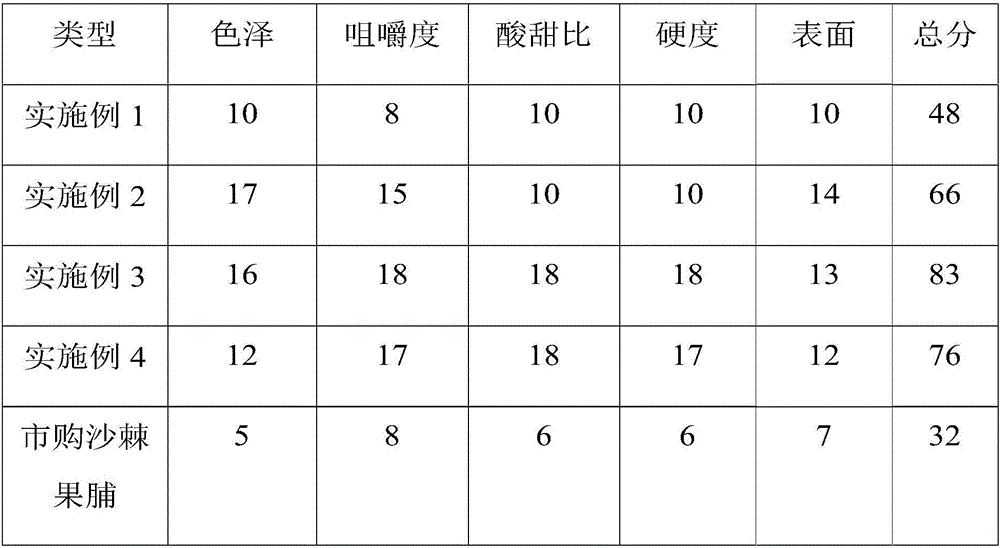

Embodiment 1

[0043] First, prepare materials according to the following weight formula: 7kg of dried seabuckthorn fruit, 1kg of dried rose, 1kg of carrageenan (carrageenan soluble in normal temperature water), 10kg of white sugar, 30kg of maltose, 0.4kg of citric acid, 0.03 potassium sorbate kg.

[0044] 1 kg of carrageenan and 25 kg of water were mixed and soaked for 2 hours to obtain sol water, which was set aside. 7 kg of dried seabuckthorn fruit, 1 kg of dried rose and 8 kg of water were mixed and boiled for 20 minutes to obtain melon flesh, and then the melon flesh was crushed with a beater to obtain fruit pulp. Add 10kg of white granulated sugar, 30kg of maltose, 0.4kg of citric acid, and 0.03kg of potassium sorbate to the fruit pulp in turn while stirring. After boiling for 15 minutes, add the prepared sol water and boil for 1 minute to obtain a mixed sol . When the mixed sol is cooled to 80°C, it is poured into a mold pan, and after cooling and molding is completed, it can be dem...

Embodiment 2

[0046] First, prepare materials according to the following weight formula: 20kg of fresh sea buckthorn fruit, 5kg of fresh rose, 2kg of carboxymethyl starch, 1kg of acid-thinned starch, 50kg of sucrose, 20kg of glucose, 0.7kg of malic acid, and 0.06kg of calcium propionate.

[0047] 2 kg of carboxymethyl starch, 1 kg of acid-thinned starch and 225 kg of water were mixed and soaked for 4 hours to obtain sol water for later use. 20 kg of fresh seabuckthorn fruit and 5 kg of fresh rose are crushed with a beater to obtain pulp, which is further crushed through a colloid mill until it can pass through a 100-mesh sieve. Then add 50kg of sucrose, 20kg of glucose, 0.7kg of malic acid, and 0.06kg of calcium propionate to the fruit pulp in turn while stirring, boil for 5 minutes, then add the prepared sol water, and boil for 5 minutes to obtain the mixed sol. When the mixed sol is cooled to 90°C, it is poured into a mold pan, and after cooling and molding is completed, it can be demould...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com