Element and method for repairing boiler crack

A crack and component technology, applied in the field of boiler maintenance, can solve problems such as difficulty in guaranteeing repair quality, and achieve remarkable technological advancement, reliable working life, and scientific and reasonable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

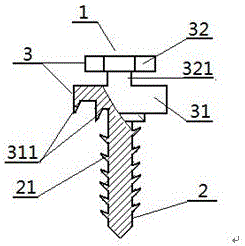

[0018] exist figure 1 Among them, the component for repairing boiler cracks of the present invention is served by the repair bolt 1 with the functions of self-tapping entry, backstop limit, multiple clamping limit, and traction of the surrounding wall. The main body of the repair bolt 1 is composed of a bolt rod 2 and a bolt head. 3, wherein: the bolt shank 2 is provided with an inverted tooth-shaped anti-retraction thread 21; the bolt head 3 includes a limit shoulder 31 provided with at least two rings of split-shaped locking teeth 311 and The control screw head 32 of the narrow neck 321 will be automatically broken off when the upper belt exceeds the limit.

[0019] exist figure 1 and figure 2 Among them, a method for repairing boiler cracks in the present invention is characterized in that it adopts the function of self-tapping entry, sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com