Sole with high elasticity including complex mid-sole and preparing method

A manufacturing method and a composite technology, which can be applied to shoe soles, footwear, footwear, etc., can solve problems such as affecting the work effect, affecting the cushioning effect, and uncomfortable wearing, so as to ensure the work strength, reduce the probability of air leakage, and improve elasticity. Durable and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

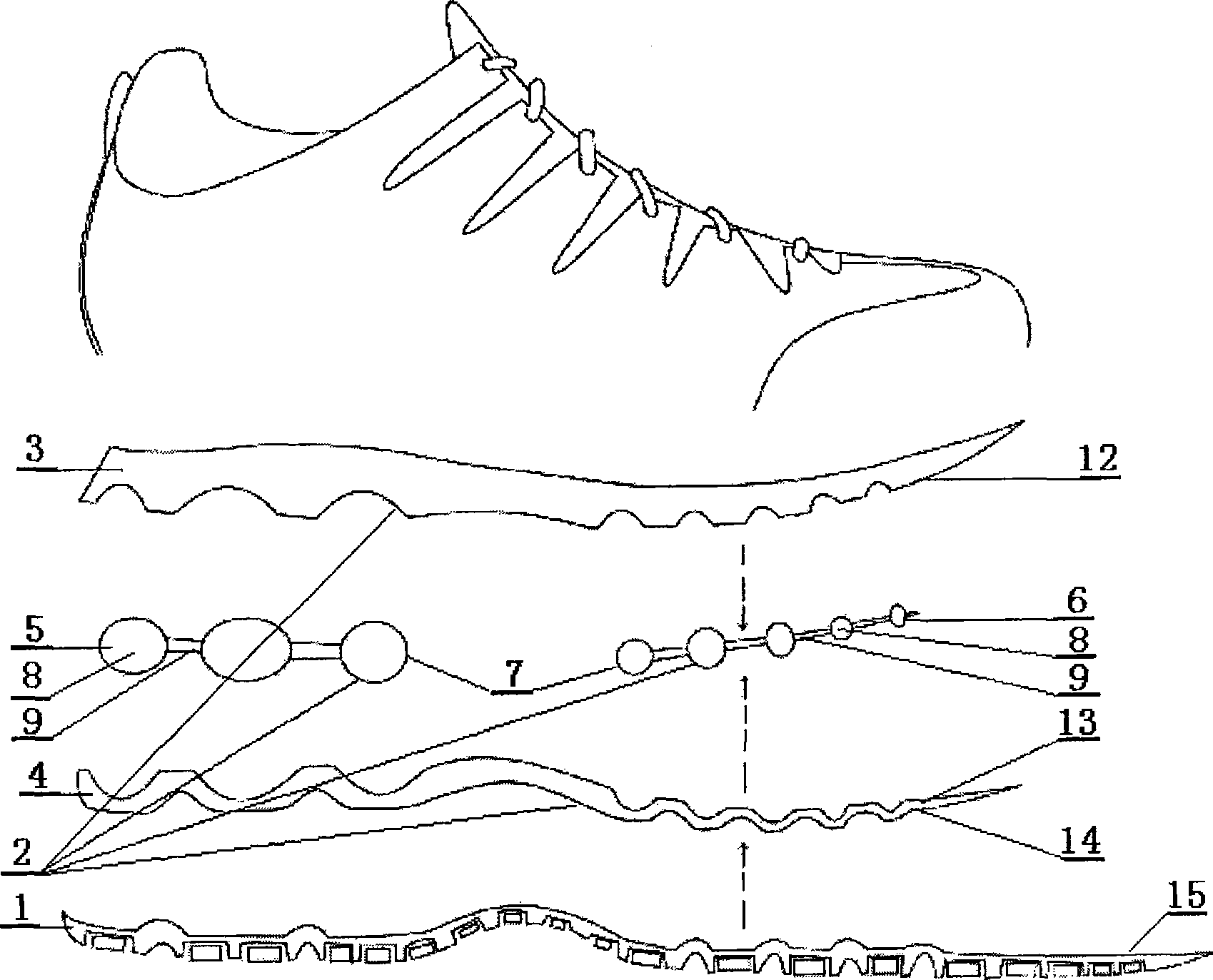

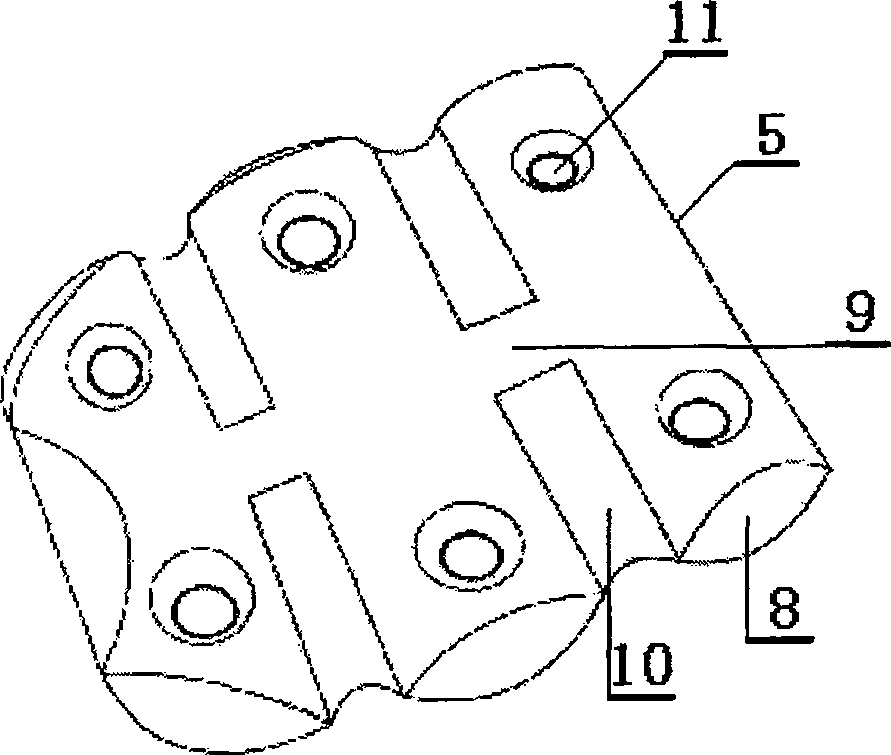

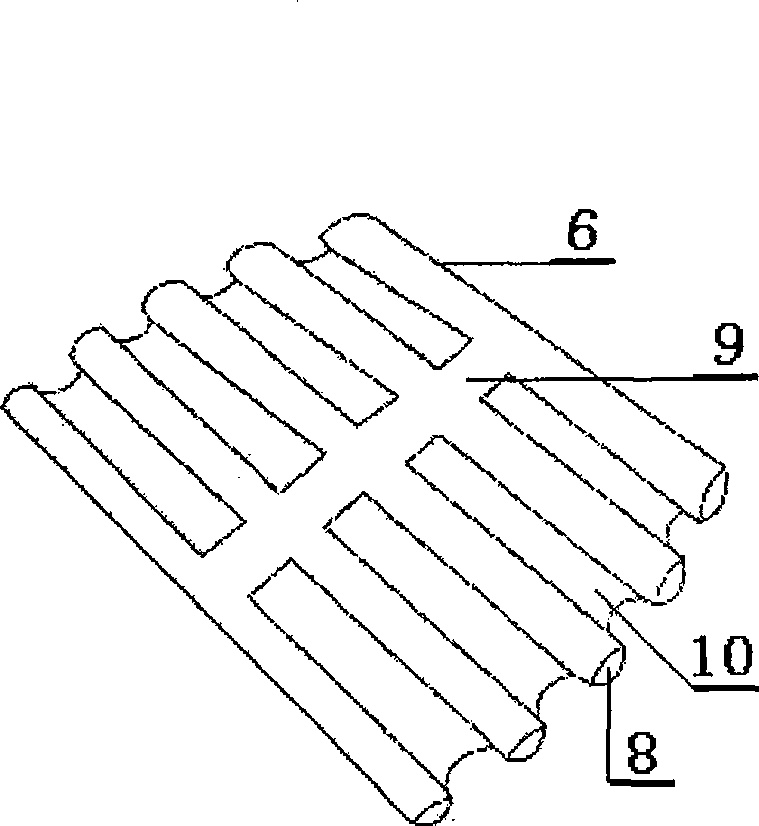

[0026] exist figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Among them, the high-elastic sole body with composite midsole of the present invention is composed of an outsole 1 and a midsole 2, and is characterized in that the midsole 2 includes an upper pad 3, a lower pad 4, and a heel airbag pad 5. The air cushion layer 7 that forms with sole portion air bag cushion 6. Among them: the heel airbag cushion 5 and the sole airbag cushion 6 are made of thermoplastic polyurethane TPU plastics, and are provided with several left and right straight air passages 8, connecting air pipes 9 connected between the left and right straight air passages 8, and the left and right straight air passages. 8 and the limiting grooves 10 on both sides of the connected trachea 9, the left and right near-ends of the left and right straight air passages 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com