A repair method for anti-roll torsion bar shaft after galvanic corrosion

An anti-roll torsion bar and galvanic corrosion technology, which is applied in the field of rework, can solve the problems of no identical or similar patent documents, high scrap rate of anti-roll torsion bar devices, high maintenance costs, etc., and achieve improved grinding Quality, increase the contact area, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

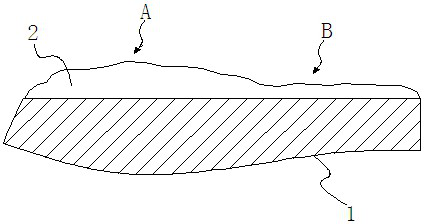

[0045] Example 1: A repair method for the anti-rolling torsion bar shaft after galvanic corrosion, which is to restore the corroded shaft end to the service requirements by spraying a coating on the shaft end of the anti-rolling torsion bar shaft Size, so as to repair the anti-roll torsion bar shaft after galvanic corrosion. After galvanic corrosion occurs, the end of the torsion bar shaft will be corroded, so that the actual size of the shaft end cannot reach the size required for use, resulting in scrapping. In this embodiment, by spraying a coating on the shaft end, the coating is used to restore the size of the shaft end after galvanic corrosion to the size required for use, so that the rusted torsion bar shaft can be repaired and the torsion bar can be extended. The service life of the shaft is reduced, the scrap rate of the torsion bar shaft is reduced, and the cost of use is reduced.

[0046] The step of described spray coating is:

[0047] a. Perform surface treatmen...

Embodiment 2

[0068] Embodiment 2: Compared with Embodiment 1, the difference is: the grinding step is:

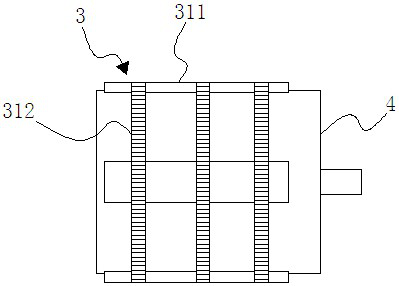

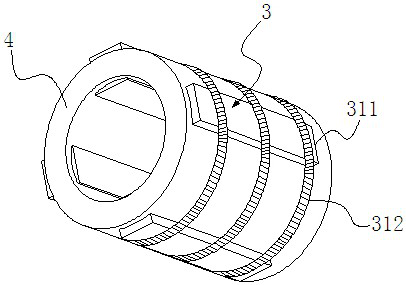

[0069] S1, first extend the coated shaft end into the inside of the grinding sleeve;

[0070] S2, placing multiple grinding blocks in multiple limiting grooves;

[0071] S3, then wind the spring one on the outside of the grinding sleeve with multiple grinding blocks, so that the spring one is in contact with the other end of the multiple grinding blocks to elastically compress the multiple grinding blocks on the multiple grinding blocks One end of a plurality of grinding blocks protrudes into the inside of the grinding sleeve to contact the coating on the end of the shaft, and then rotates the grinding sleeve for grinding.

Embodiment 3

[0072] Embodiment 3: as Figure 6 As shown, compared with Embodiment 1, the difference lies in that an arc-shaped inner groove 6 is formed on the upper base of the trapezoidal grinding block 311 . This can increase the contact area with the coating, thereby further improving the grinding quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com