Heavy oil/ residual oil/ coal tar catalytic cracking-polymerization reaction lightweight device and method thereof

A catalytic cracking unit and catalytic cracking technology are applied in the fields of petrochemical industry, oil refining and coal chemical industry, which can solve the problems of large thermal energy loss, high equipment investment, low gasoline yield, etc. The effect of a short payback period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

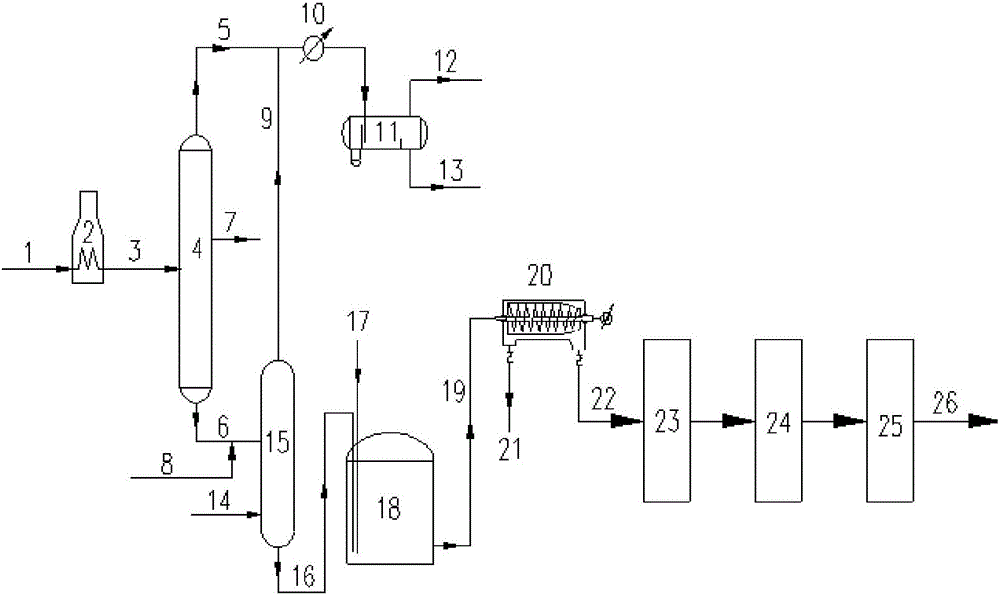

[0043] Such as figure 1 The heavy oil / residual oil / coal tar catalytic cracking-polymerization lightening device of the present invention includes a catalytic cracking device, the output end of the heating furnace is connected with the catalytic cracking device, and the catalytic cracking device is connected with the polymerization reaction The upper part of the polymerization reactor is connected with the condenser, the lower part of the polymerization reactor is connected with the mixing vessel, and the output end of the mixing vessel is connected with the water washing device, the purging device and the classification device in sequence through the centrifuge. The catalytic cracking unit includes a reaction-regeneration system, a fractionation system and an absorption-stabilization system.

[0044] The raw oil f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com