Modified polyphenylene ether composition and preparation method thereof

A technology of polyphenylene ether and composition, which is applied in the field of modified polyphenylene ether composition and preparation for pipelines, which can solve the problems of loose combination of steel wire and plastic, reduced safety and reliability, short service life, etc., and achieve the test duration Long, excellent mechanical strength, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

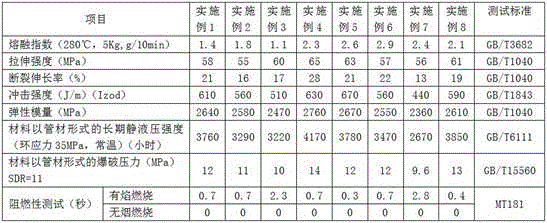

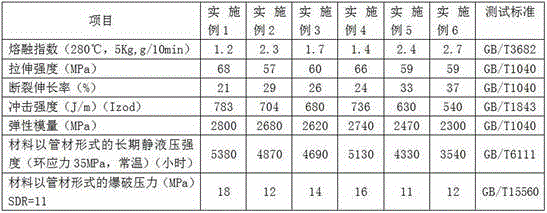

Examples

Embodiment 1

[0098]Polyphenylene ether resin (PPO / PPE, number average molecular weight about 21500) 75%, styrene-ethylene / butylene-styrene copolymer (SEBS) 18%, tetrakis[β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 10101) 0.2%, tris [2.4-di-tert-butylphenyl] phosphite (antioxidant 168) 0.2%, zinc sulfide (ZnS ) 2.5%, nano-montmorillonite 4.1%, coupling agent 0.4%.

[0099] Among them, the nano-montmorillonite is treated with a coupling agent, and a high-speed stirring device with a strong shear function is used for surface treatment at a temperature of 60-90°C.

[0100] Preparation method: polyphenylene ether resin (PPO / PPE), styrene-ethylene / butylene-styrene copolymer (SEBS), tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) propionate] pentaerythritol ester (antioxidant 10101), tris [2.4-di-tert-butylphenyl] phosphite (antioxidant 168), zinc sulfide (ZnS), nano-montmorillonite (after coupling Joint agent treatment, the same below) into the high mi...

Embodiment 2

[0102] Polyphenylene ether resin (PPO / PPE, number average molecular weight about 21500 and number average molecular weight about 16000 compound ratio 5-10:1) 77%, styrene-ethylene / butylene-styrene copolymer (SEBS) 15%, Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester (antioxidant 10101) 0.2%, tris[2.4-di-tert-butylphenyl]phosphorous acid Ester (antioxidant 168) 0.2%, zinc sulfide (ZnS) 3%, nano-montmorillonite 4.6%, coupling agent 0.4%.

[0103] Among them, the nano-montmorillonite is treated with a coupling agent, and a high-speed stirring device with a strong shear function is used for surface treatment at a temperature of 60-90°C.

[0104] Preparation method: polyphenylene ether resin (PPO / PPE), styrene-ethylene / butylene-styrene copolymer (SEBS), tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) Propionic acid] pentaerythritol ester (antioxidant 10101), tris [2.4-di-tert-butylphenyl] phosphite (antioxidant 168), zinc sulfide (ZnS), and nano-mont...

Embodiment 3

[0106] Polyphenylene ether resin (PPO / PPE, number average molecular weight about 21500 and number average molecular weight about 17000 compound ratio 2-5:1) 77%, styrene-ethylene / butylene-styrene copolymer (SEBS) 15%, Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester (antioxidant 10101) 0.2%, tris[2.4-di-tert-butylphenyl]phosphorous acid Ester (antioxidant 168) 0.2%, zinc sulfide (ZnS) 3%, nano-montmorillonite 4.6%, coupling agent 0.2%.

[0107] Among them, the nano-montmorillonite is treated with a coupling agent, and a high-speed stirring device with a strong shear function is used for surface treatment at a temperature of 60-90°C.

[0108] Preparation method: polyphenylene ether resin (PPO / PPE), styrene-ethylene / butylene-styrene copolymer (SEBS), tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) Propionic acid] pentaerythritol ester (antioxidant 10101), tris [2.4-di-tert-butylphenyl] phosphite (antioxidant 168), zinc sulfide (ZnS), and nano-montm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com