Polyvinyl alcohol hydrogel, method for preparing same and application of polyvinyl alcohol hydrogel

A technology of polyvinyl alcohol and polyvinyl alcohol solution, applied in medical science, prosthesis, etc., can solve the problems of easy damage, poor hydrogel strength, instability, etc., achieve short time, improve accuracy, and ensure uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The 3rd technical problem to be solved in the present invention is to provide a kind of preparation method of polyvinyl alcohol hydrogel microtube, comprising the steps:

[0041] 1) Preparation of polyvinyl alcohol solution: Polyvinyl alcohol and an organic solvent are heated and dissolved at 110°C to 145°C to obtain a polyvinyl alcohol solution. The organic solvent is dimethyl sulfoxide (DMSO) and N-N, dimethyl formazan The mixed solvent of amide (DMF), the volume ratio of dimethylsulfoxide (DMSO) and N-N, dimethylformamide (DMF) is 0.25-1; the mass concentration of the obtained polyvinyl alcohol solution is 10-30%;

[0042] 2) Preparation of microtubes: casting the polyvinyl alcohol solution obtained in step 1) into a mold, standing to cool to room temperature to form polyvinyl alcohol microtubes with a gel structure, and then using solution extraction to remove the organic solvent therein;

[0043]The mold comprises: a mold body 1 and a mold core 2; the mold body 1 h...

Embodiment 1

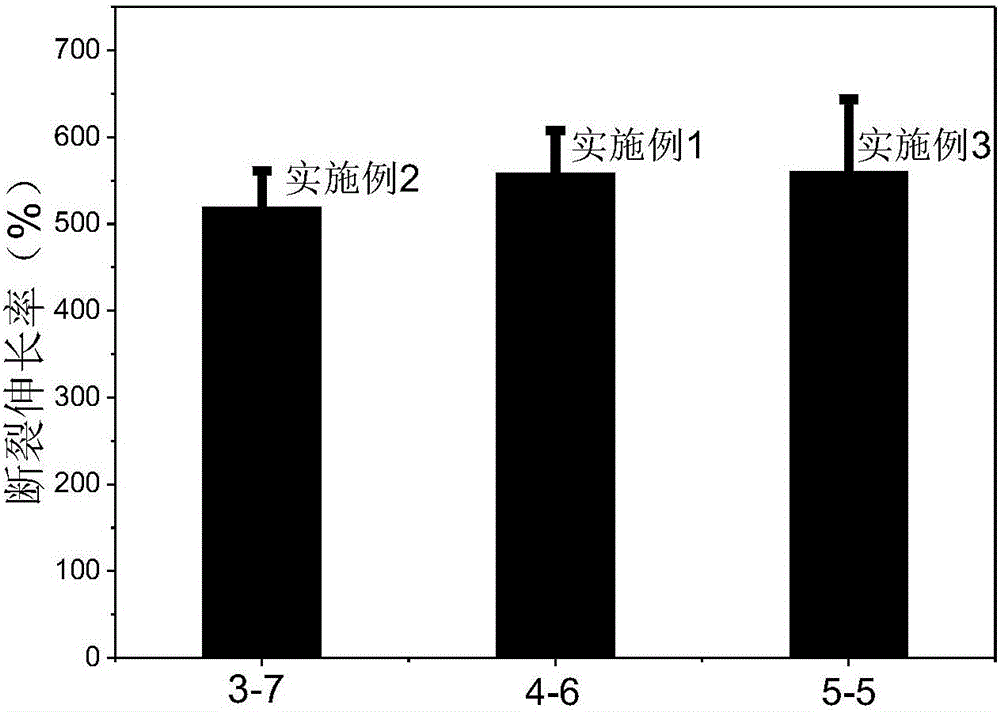

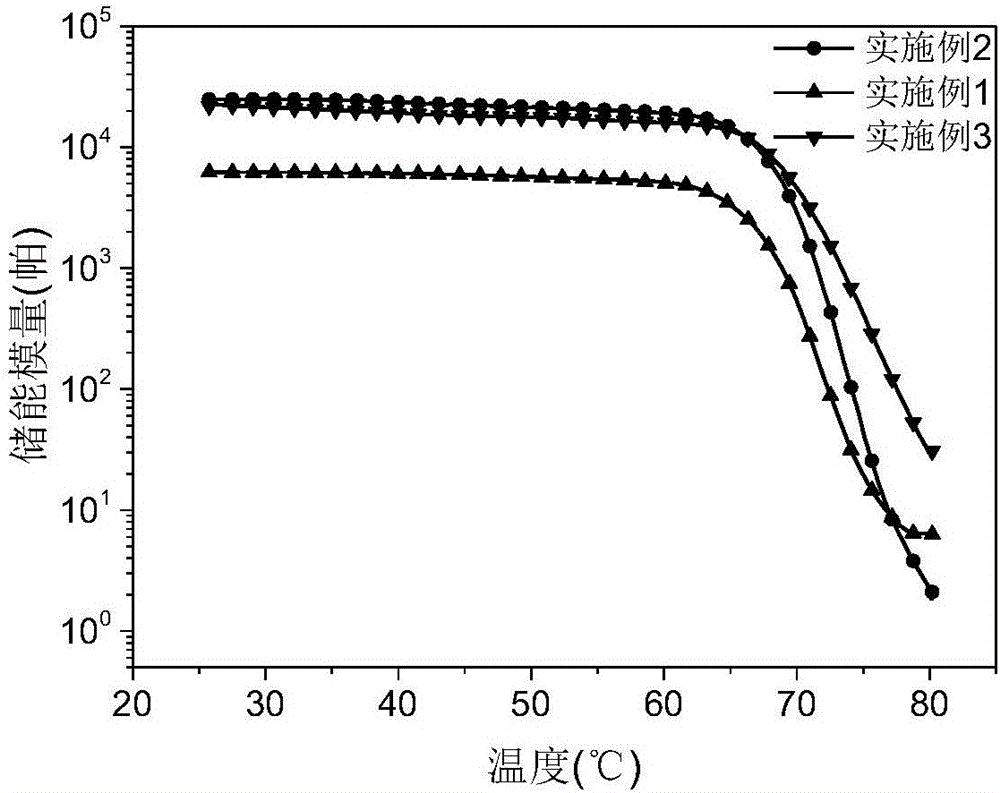

[0055] The preparation of embodiment 1 polyvinyl alcohol hydrogel

[0056] Weigh 11 grams of polyvinyl alcohol (PVA), dry at 60 degrees Celsius for 24 hours, weigh 35.20 grams of DMSO, 45.48 grams of DMF (the volume ratio of DMSO to DMF is 4:6), seal the bottle, and place it into a room with a temperature of 130 degrees. Heat in an oven (or in an oil bath) until the PVA is completely dissolved, and stir with a magnetic stirrer to dissolve the PVA evenly to obtain a PVA solution; let the PVA solution stand and cool down to room temperature naturally, and stand at room temperature for 6 hours to ensure that the PVA gel is fully formed. crosslinking. Remove the organic solvent in the PVA gel by solvent extraction: soak the prepared PVA gel in deionized water, replace the deionized water every 6 hours, and circulate 4-6 times. A standard tensile sample of PVA gel was prepared for tensile test and rheological performance test to characterize the mechanical properties and thermal s...

Embodiment 2

[0057] The preparation of embodiment 2 polyvinyl alcohol hydrogel

[0058] Weigh 10.84 grams of polyvinyl alcohol (PVA), dry at 60 degrees Celsius for 24 hours, weigh 26.4 grams of DMSO, 53.06 grams of DMF (the volume ratio of DMSO to DMF is 3:7), the bottle is sealed, and placed in a room with a temperature of 130 degrees. Heat in an oven (or in an oil bath) until the PVA is completely dissolved, and stir with a magnetic stirrer to dissolve the PVA evenly to obtain a PVA solution; let the PVA solution stand and cool down to room temperature naturally, and stand at room temperature for 6 hours to ensure that the PVA gel is fully formed. crosslinking. Remove the organic solvent in the PVA gel by solvent extraction: soak the prepared PVA gel in deionized water, replace the deionized water every 6 hours, and circulate 4-6 times. A standard tensile sample of PVA gel was prepared for tensile test and rheological performance test to characterize the mechanical properties and therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com