Graphene composite conductive material and preparation method

A graphene composite and conductive material technology, applied in the field of water-based electrode materials or composite materials, can solve the problems of inability to form π-π interaction, poor effect of improving electrical properties of materials, poor dispersion uniformity of graphene, etc., and achieves the preparation method Simple and reliable, excellent electrical properties and film-forming properties, good film-forming and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

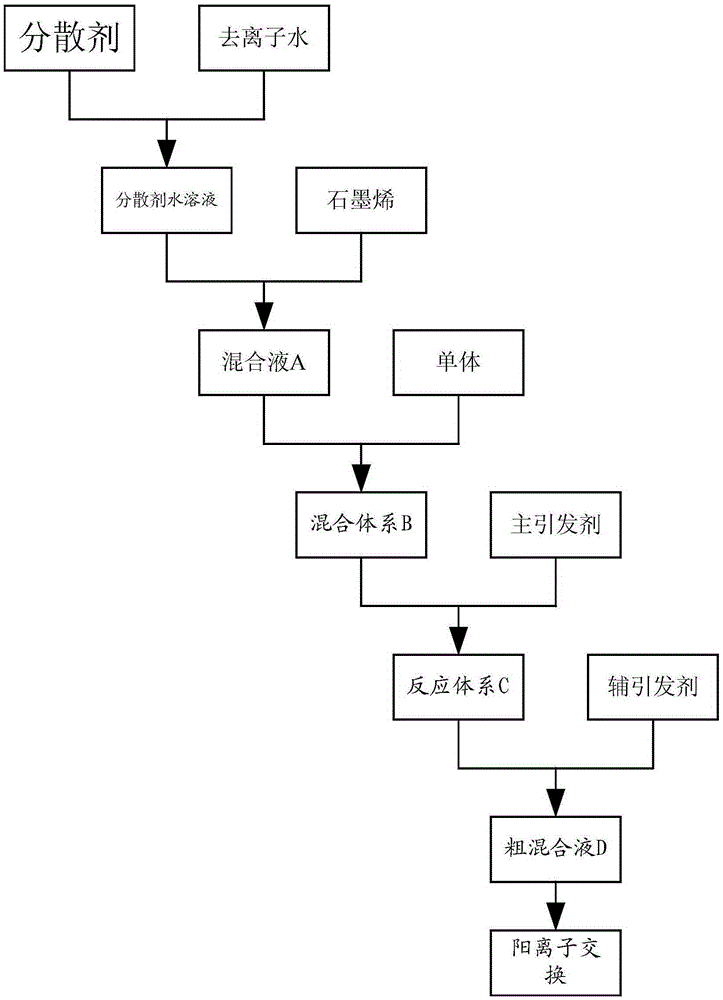

[0037] Preparation methods such as figure 1shown in the following steps:

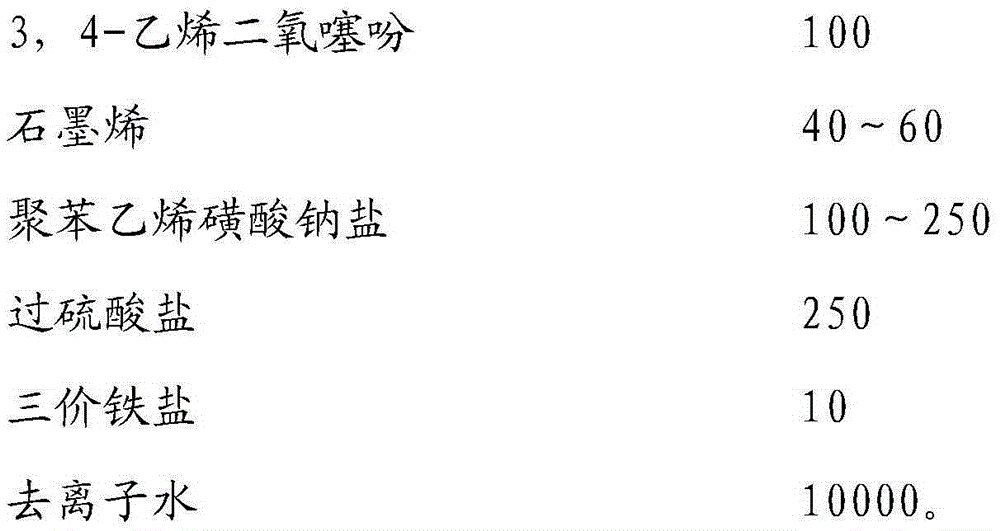

[0038] 1. Weigh 20g polystyrene sulfonate sodium salt (molecular weight>100000), and dissolve it in 1000mL deionized water. After being completely dissolved, 6 g of graphene was added to the solution, stirred rapidly for 30 minutes and then ultrasonicated for 2 hours until completely dispersed.

[0039] 2. Add 10 g of 3,4-ethylenedioxythiophene monomer dropwise to the above mixture, and keep stirring at 10°C until the system is uniform and stable.

[0040] 3. With 25g main initiator ammonium persulfate ((NH 4 ) 2 · SO 4 ) into the mixing system, fully stirred until completely dissolved.

[0041] 4. The co-initiator iron sulfate (Fe 2 (SO 4 ) 3 ) solution was added dropwise to the reaction system in an amount of 20 mL, and then reacted in an ice-water bath for 24 hours to obtain a crude mixed solution.

[0042] 5. Exchanging the crude mixed solution with a cation exchange resin to remove residua...

Embodiment 2

[0045] Except changing the amount of graphene to 5g, the remaining amount, preparation and film-forming methods and steps are the same as in Example 1. The electrical conductivity, seebeck coefficient and film-forming properties of the final film are shown in Table 1.

Embodiment 3

[0047] Except that the amount of graphene is changed to 4g, the remaining amount, preparation and film-forming methods and steps are the same as in Example 1. The electrical conductivity, seebeck coefficient and film-forming properties of the final film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com