A method for treating vanadium industrial wastewater with semi-dry flue gas desulfurization ash

A technology for industrial wastewater and desulfurization ash, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of incomplete discharge, low treatment efficiency, high treatment cost, etc., and solve secondary pollution And the problem of land occupation, good treatment effect and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

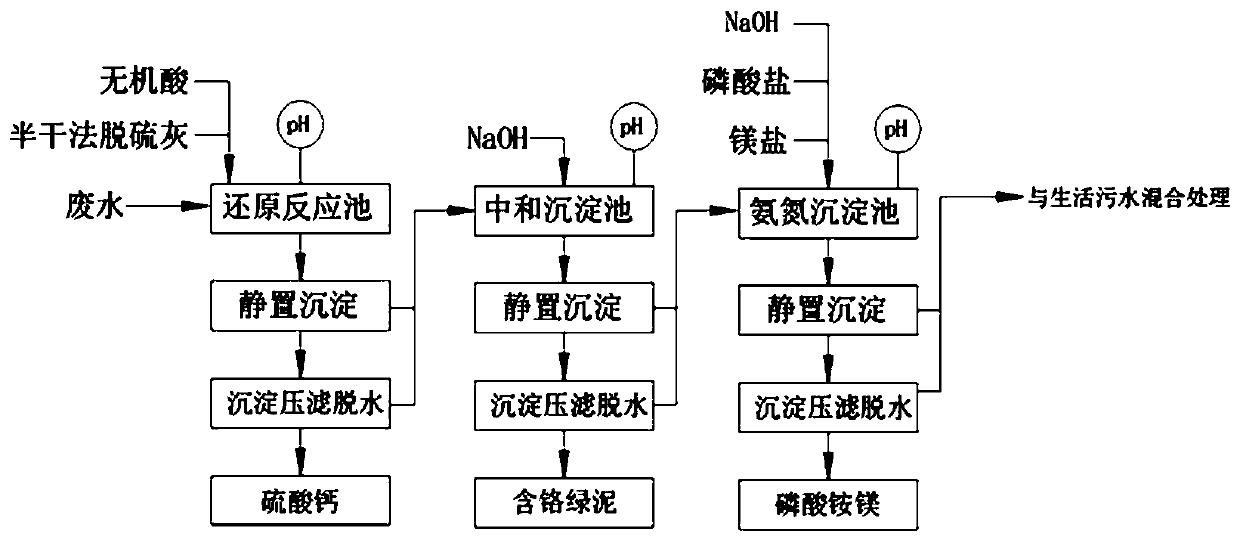

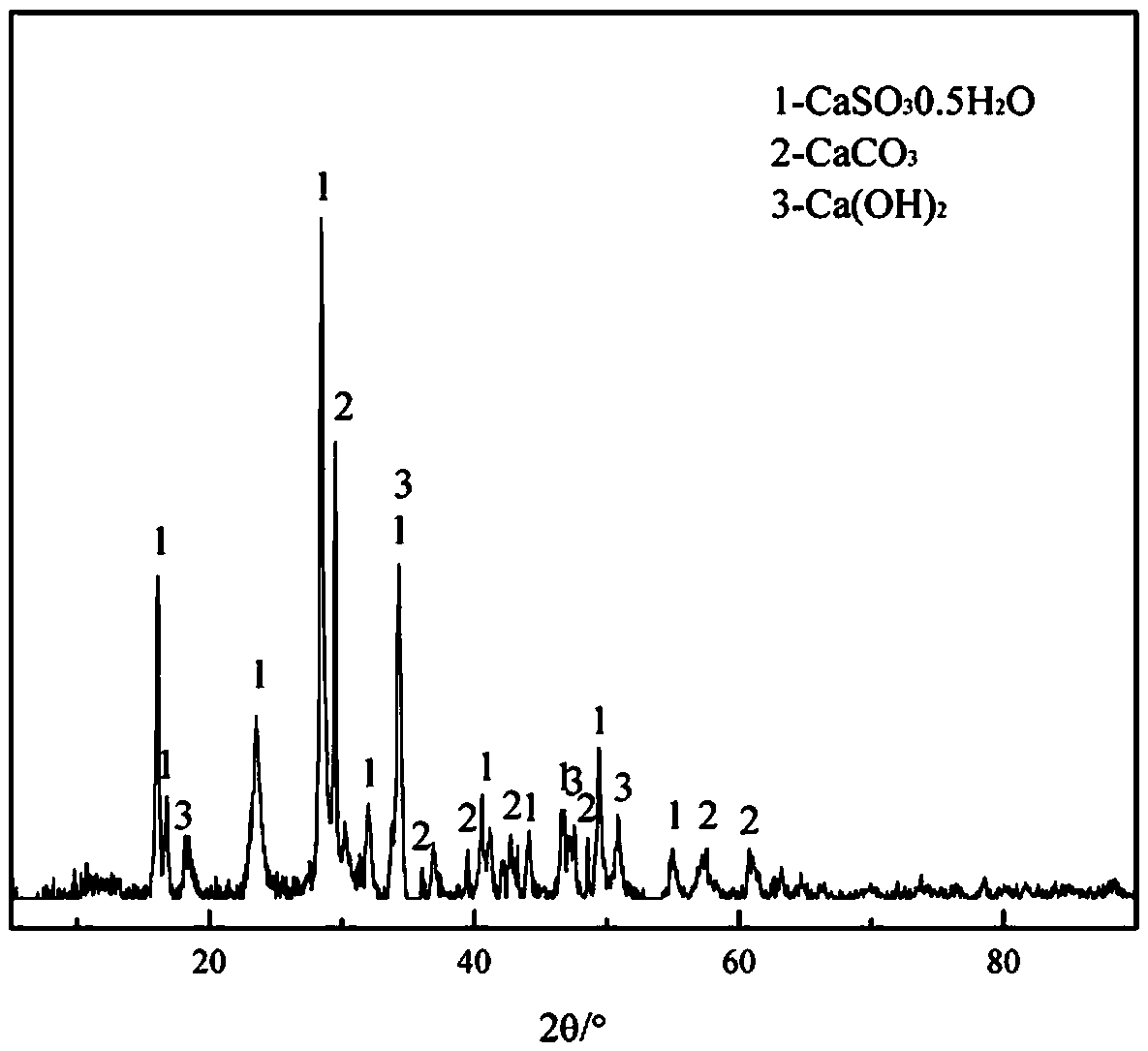

[0034] The pH of vanadium industrial wastewater is 1, the total chromium concentration is 4500 mg / L, the hexavalent chromium concentration is 3800 mg / L, the pentavalent vanadium concentration is 200 mg / L, and the ammonia nitrogen (NH 3 -N) concentration 4000mg / L; introduce vanadium industrial wastewater into the reduction reaction tank, stir and add semi-dry FGD ash; the amount of semi-dry FGD ash added is 10% of the total mass of vanadium and chromium in vanadium industrial wastewater times; the XRD pattern of semi-dry flue gas desulfurization ash is as follows figure 2 shown;

[0035] Add inorganic acid to adjust the pH=1.0 of all materials in the reduction reaction tank, and then reduce the reaction for 30min under stirring conditions to reduce the high valence state of vanadium and chromium to low valence state; the inorganic acid is sulfuric acid;

[0036] After the reduction reaction is completed, it is left to stand for precipitation for 2 hours, and the primary super...

Embodiment 2

[0042] The method is the same as in Example 1, except that:

[0043] (1) The pH of vanadium industrial wastewater is 2, the total chromium concentration is 4200 mg / L, the hexavalent chromium concentration is 3600 mg / L, the pentavalent vanadium concentration is 150 mg / L, and the ammonia nitrogen (NH 3 -N) concentration 3600mg / L; introduce vanadium industrial wastewater into the reduction reaction tank, stir and add semi-dry FGD ash; the amount of semi-dry FGD ash added is 8% of the total mass of vanadium and chromium in vanadium industrial wastewater times;

[0044] (2) Add inorganic acid to adjust the pH=2.0 of all materials in the reduction reaction tank, and then react under stirring conditions for 20min; the inorganic acid is hydrochloric acid;

[0045] (3) After the reduction reaction is completed, stand for precipitation for 1.5h;

[0046] (4) Introduce the primary mixed solution into the neutralization and sedimentation tank, add sodium hydroxide to adjust pH=7.0, stir...

Embodiment 3

[0052] The method is the same as in Example 1, except that:

[0053] (1) The pH of vanadium industrial wastewater is 2, the total chromium concentration is 3800 mg / L, the hexavalent chromium concentration is 3400 mg / L, the pentavalent vanadium concentration is 100 mg / L, and the ammonia nitrogen (NH 3 -N) concentration of 3200mg / L; introduce vanadium industrial wastewater into the reduction reaction tank, stir and add semi-dry FGD ash; the amount of semi-dry FGD ash added is 6% of the total mass of vanadium and chromium in vanadium industrial wastewater times;

[0054] (2) Add inorganic acid to adjust the pH=2.0 of all materials in the reduction reaction tank, and then react under stirring conditions for 15 minutes; the inorganic acid is nitric acid;

[0055] (3) After the reduction reaction is completed, stand for precipitation for 1h;

[0056] (4) Introduce the primary mixed solution into the neutralization and sedimentation tank, add sodium hydroxide to adjust pH=8.0, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com