Machine for automatically removing piston-ring tread opening burrs

A technology of piston ring and burr machine, which is applied in the direction of grinding frame, grinding feed motion, grinding machine parts, etc., can solve the problems of occupational disease risk, uneven force, low efficiency, etc. The effect of quality risk, reducing labor intensity of employees and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

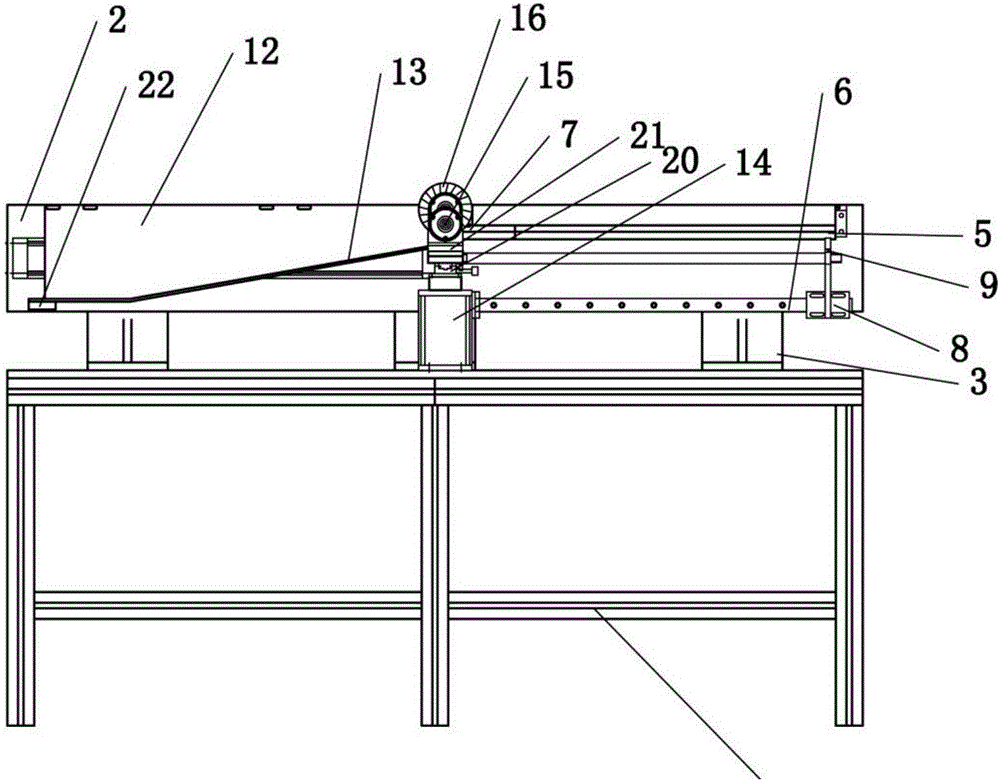

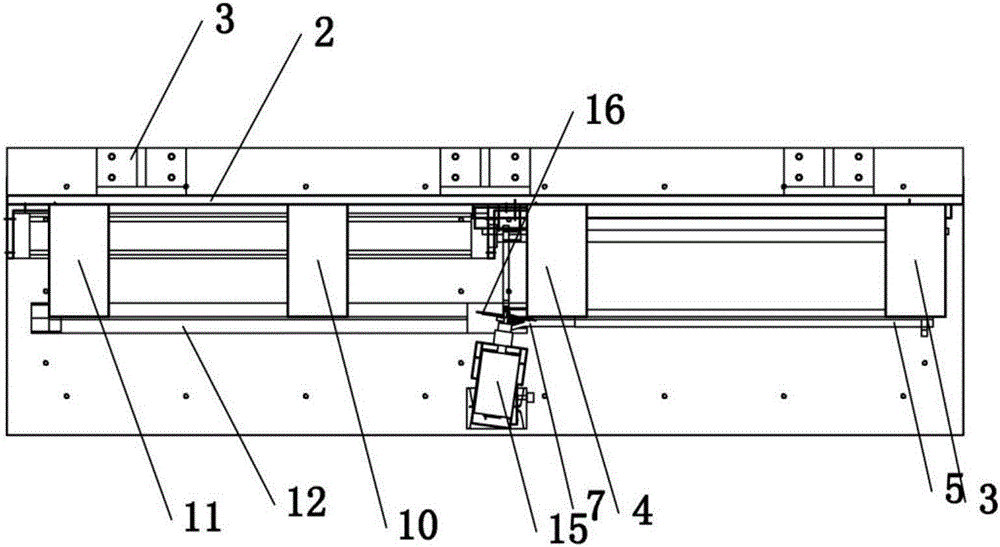

[0020] The present invention will be further explained in conjunction with the accompanying drawings.

[0021] Such as Figure 1 to Figure 6 The shown automatic deburring machine for piston ring step surface openings includes a frame 1 and a back plate 2, the back plate 2 is arranged on the frame 1 through the mounting bracket 3, the frame 1 is provided with a grinding mechanism, and the back plate 2. There is a feeding mechanism and a receiving mechanism;

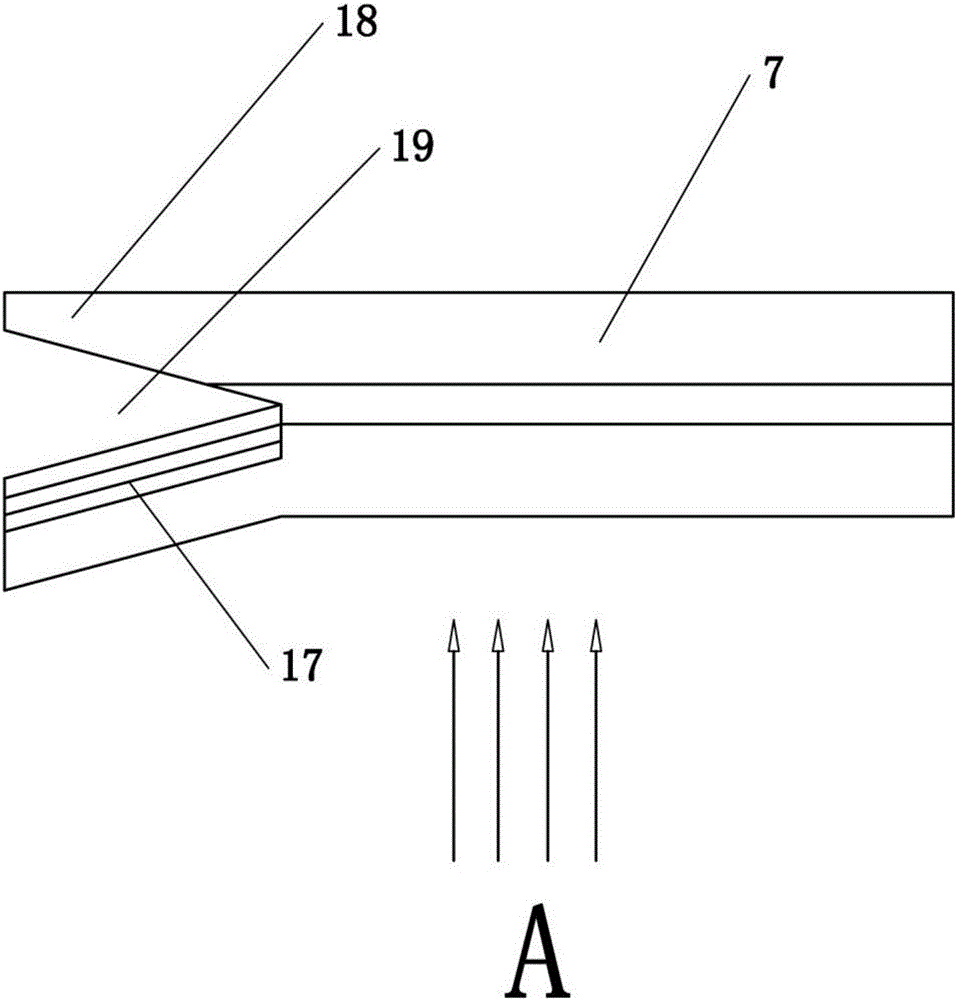

[0022] The feeding mechanism comprises a first feeding boom 4, a second feeding boom 5, a tail end support 6, a transmission guide rail 7 and a guiding device 8, the first feeding boom 4 and the second feeding boom 5 are all arranged on the back plate 2, the second feeding boom 4 The other end of the first feeding cantilever 4 is provided with a tail end bracket 6, the other end of the second feeding cantilever 5 is provided with a guide 8, the backboard 2 is also provided with a transmission guide rail 7, and the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com