Low-pressure-drop liquid collector applicable to large tower

A liquid collector and low pressure drop technology, applied in the field of separation towers, can solve the problems of difficult structural manufacturing and installation, short liquid residence time, and inability to achieve good vapor distribution effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

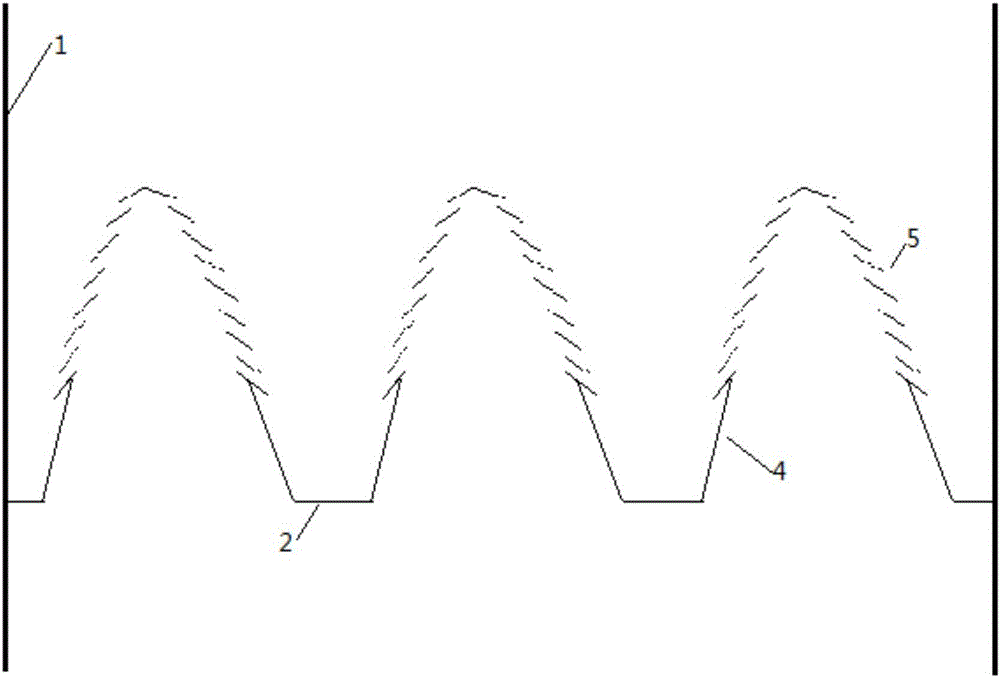

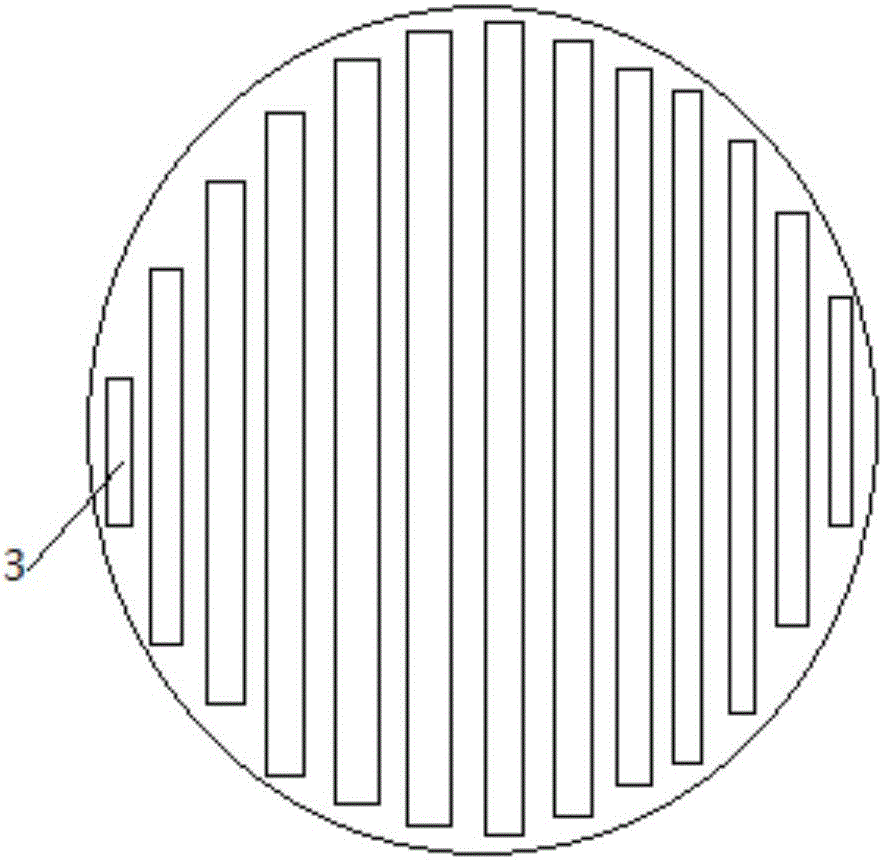

[0020] In an embodiment, a low-pressure drop liquid collector suitable for a large column is integrated by the following structure: there are parallel rectangular strip holes (3) on the bottom plate (2) of the oil collection tank, and the opening ratio is the cross-sectional area of the column More than 50% of the hole, the two ends of the hole are more than 100mm away from the tower wall, the bottom plate is completely connected to the tower wall by 0°-9° downwards along the direction of the long hole, and the top of the rectangular long hole (3) is completely connected to the riser wall (4) The riser wall (4) is a strip groove, the section along the strip direction is a positive trapezoidal structure, the two ends are vertical vertical plates, and the vertical height of the positive trapezoidal wall is 200-1000mm; the upper end of the positive trapezoidal wall is equipped with 3-30 layers of long rectangular plates connected in parallel to form a tower-type roof (5), the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com