Engraving vamp fabric and manufacturing method

A manufacturing method and fabric technology, which is applied in the direction of shoe uppers, footwear, and techniques for producing decorative surface effects, etc., can solve the problem of affecting the aesthetics of the upper, the upper fabric is prone to warping in the carved area, and the impact on the upper fabric Strength and service life and other issues, to achieve the effect of increasing visual and tactile effects, good visual and tactile effects, and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

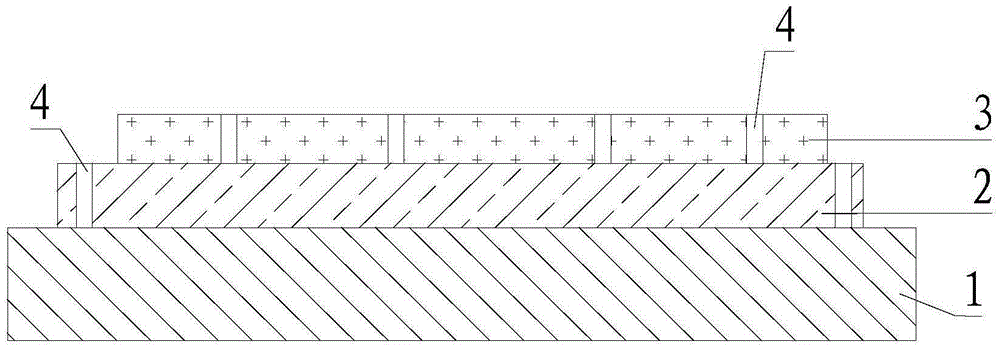

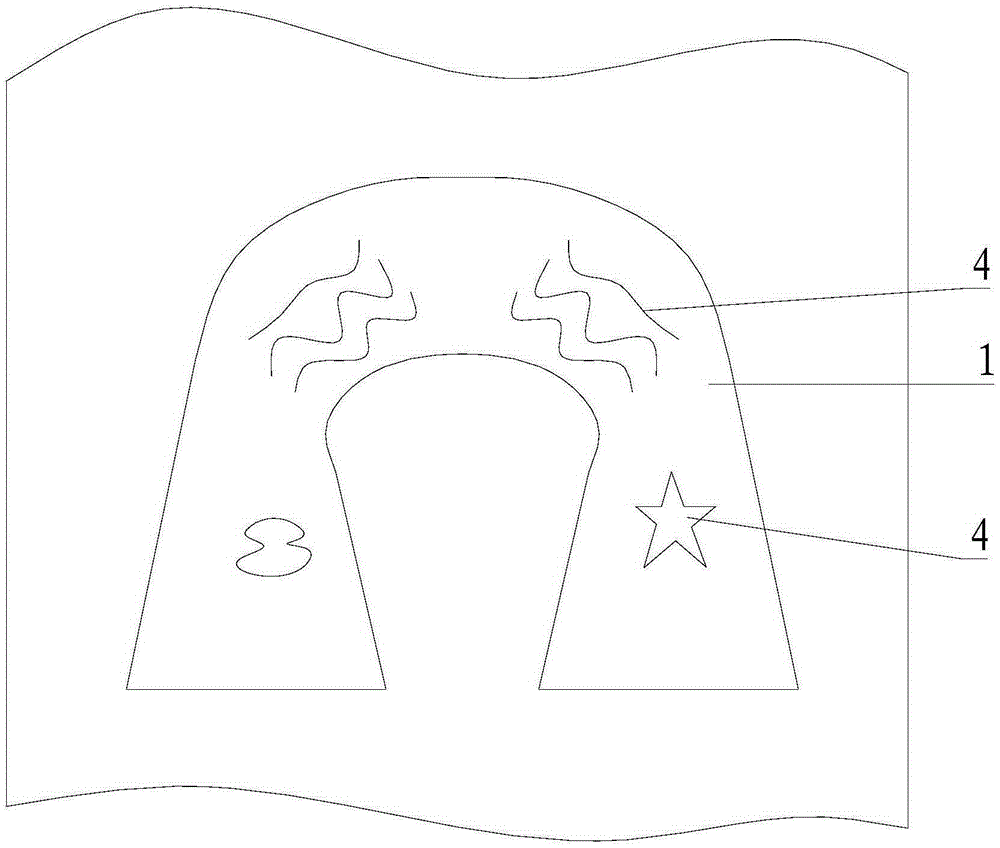

[0053] Please refer to Figure 1 to Figure 2 , Embodiment 1 of the present invention is:

[0054] A kind of carved shoe upper fabric, comprising an insulating cloth layer 1, and further comprising a foaming ink layer 2 and an ink layer 3 sequentially arranged on the insulating cloth layer 1, the pattern of the ink layer 3 is located on the foaming ink layer 2 Within the graphic range, the ink layer 3 and / or the foamed ink layer 2 are provided with carved patterns 4, and the carved patterns 4 of the ink layer 3 are connected or not connected with the carved patterns 4 on the foamed ink layer 2, so The thickness of the embossed pattern 4 on the ink layer 3 is the same as or different from the thickness of the embossed pattern 4 on the foamed ink layer 2; preferably, the insulating cloth layer 1 is a textured cloth.

[0055] During production, the foamed ink layer 2 and the ink layer 3 are printed on the insulating cloth layer 1 through screen printing in sequence, and carved pa...

Embodiment 2

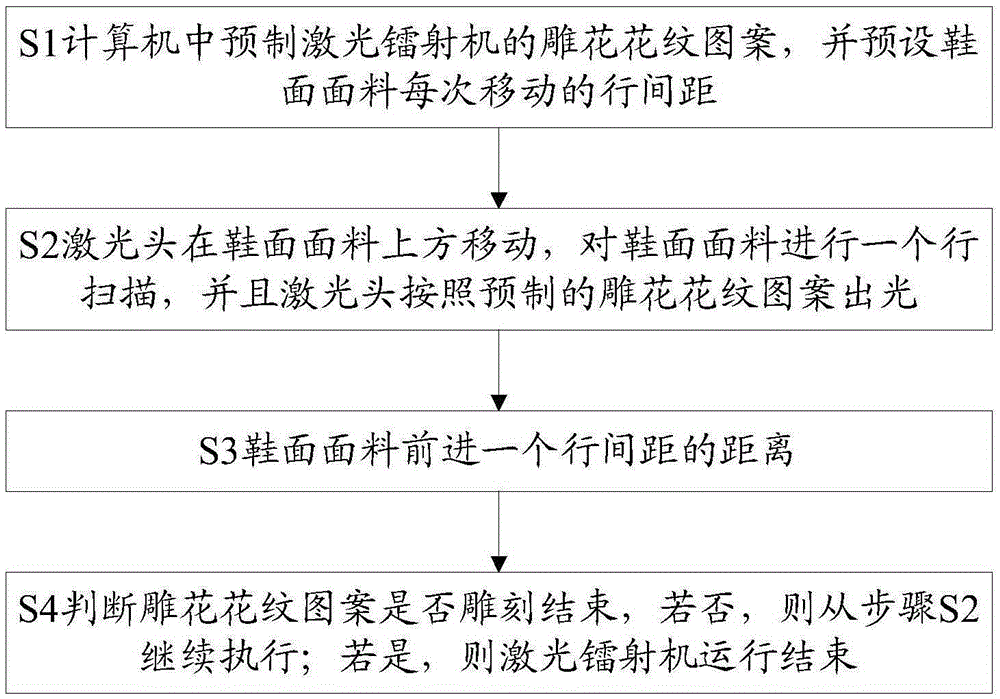

[0056] Please refer to image 3 , the second embodiment of the present invention is:

[0057] A method for making a carved shoe upper fabric,

[0058] The S1 computer prefabricated the engraving pattern of the laser laser machine, and preset the line spacing of each movement of the upper fabric;

[0059] The S2 laser head moves above the upper fabric, scans the upper fabric in a row, and the laser head emits light according to the prefabricated carved patterns, specifically:

[0060] S21 The laser head moves to the edge of a row of the upper fabric, and the column spacing of the laser head moves is prefabricated;

[0061] S22 judges whether the laser head runs to another row edge of the shoe upper fabric, if so, then execute step S3; if not, then continue to execute down;

[0062] S230 installs a camera around the laser head, the camera scans to obtain the deformation of the upper fabric, and corrects the carved pattern according to the deformation of the upper fabric, spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com