Processing process for collar points and sleeve caps of non-ironing shirt

A technology for processing technology and cuffs, which is applied in the field of clothing, can solve the problems of high friction, the influence of shirt strength, and the strength reduction of collar points and cuffs, so as to increase the number of times of washing resistance, ensure shape retention performance, and improve the quality of shirts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

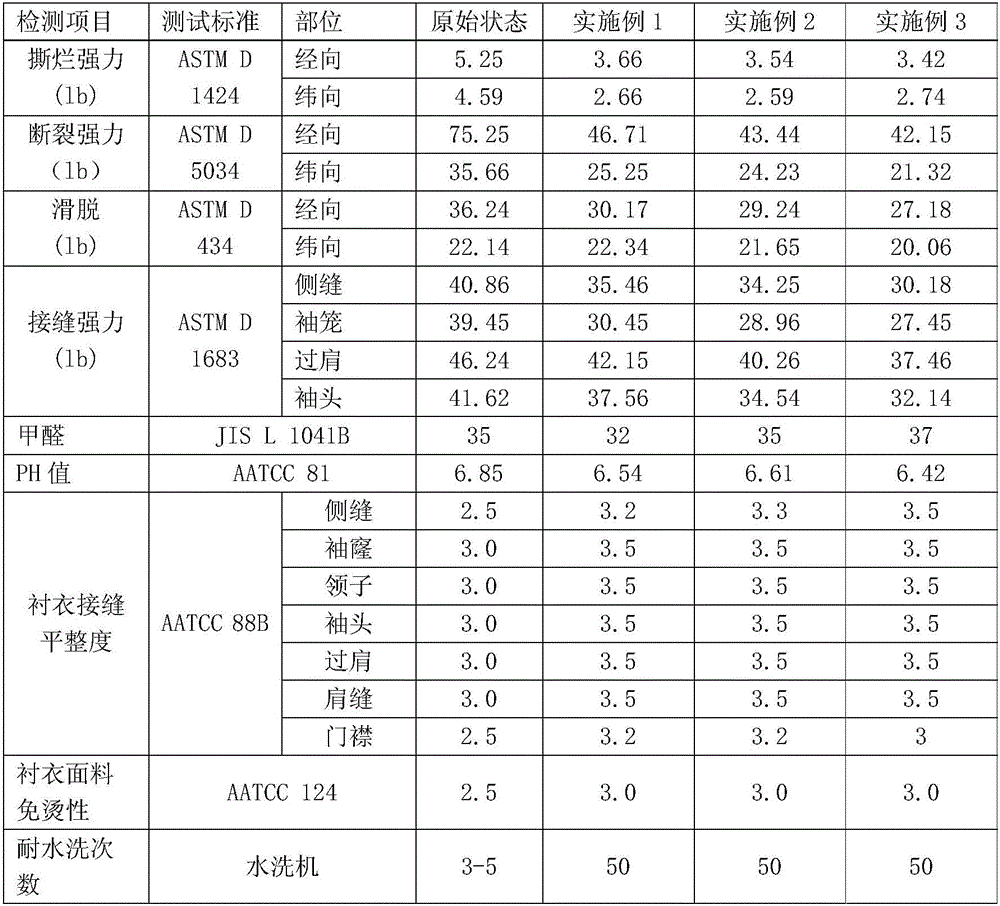

Examples

Embodiment 1

[0012] Embodiment 1, concrete steps are as follows:

[0013] 1) The three-proof additive solution uses fluorine three-proof additive with a concentration of 10g / L. Before the shirt is finished without ironing, soak the shirt collar and sleeves in the three-proof additive solution for 30 seconds, and then wash the collar and sleeves with clean water. Sleeves, then dry at 30°C;

[0014] 2) Spray finishing solution: in the finishing solution, the concentration of Fusiping resin ELF is 120g / L, the concentration of Fusiping catalyst F-M is 30g / L, the concentration of organic silicon softener FMW is 40g / L, polyethylene protection The concentration of the agent HDP is 20g / L, the concentration of the surfactant MRZ is 3g / L, and the rest is water, and the shirt is sprayed to make the liquid-carrying rate 75%;

[0015] 3) Soak the collar and sleeves of the shirt in a phosphoric acid solution with a concentration of 5g / L for 20s, then wash the collar and sleeves with water, and then dry...

Embodiment 2

[0017] Embodiment 2, concrete steps are as follows:

[0018] 1) The three-proof auxiliary agent solution uses fluorine three-proof auxiliary agent with a concentration of 20g / L. Before finishing the shirt without ironing, soak the shirt collar and sleeves in the three-proof auxiliary agent solution for 25 seconds, and then wash the collar and sleeves with clean water. Sleeves, then dry at 40°C;

[0019] 2) Spray finishing liquid: in the finishing liquid, the concentration of Fusiping resin SW is 140g / L, the concentration of Fusiping catalyst F-M is 45g / L, the concentration of organic silicon softener NUP is 30g / L, and polyethylene protection The concentration of the agent CAN is 30g / L, the concentration of the surfactant MRZ is 5g / L, and the rest is water. Spray the shirt to make the liquid-carrying rate 80%;

[0020] 3) Soak the collar and sleeves of the shirt in a phosphoric acid solution with a concentration of 7g / L for 25s, then wash the collar and sleeves with water, and...

Embodiment 3

[0022] Embodiment 3, concrete steps are as follows:

[0023] 1) The three-proof additive solution uses fluorine three-proof additive with a concentration of 30g / L. Before finishing the shirt without ironing, soak the shirt collar and sleeves in the three-proof additive solution for 20 seconds, and then wash the collar and sleeves with clean water. Sleeves, then dry at 40°C;

[0024] 2) Spray finishing liquid: the concentration of F-AP Fusiping resin SW in the finishing liquid is 150g / L, the concentration of Fusiping catalyst F-M is 40g / L, the concentration of organic silicon softener NUP is 40g / L, poly The concentration of the vinyl protective agent CAN is 40g / L, the surfactant MRZ is 6g / L, and the rest is water. Spray the shirt to make the liquid carrying rate 80%;

[0025] 3) Soak the collar and sleeves of the shirt in a phosphoric acid solution with a concentration of 8g / L for 30s, then wash the collar and sleeves with water, and then dry them at 50°C;

[0026] 4) Pre-dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com