Comb-like blade structure and using method thereof

A comb-shaped and blade technology, applied in the field of comb-shaped blade structure, can solve the problems of inability to achieve stable cutting, reduce heat generation, inconvenience, etc., to prevent the blade from loosening and affect the work quality, expand the scope of use, and the design is reasonable and simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

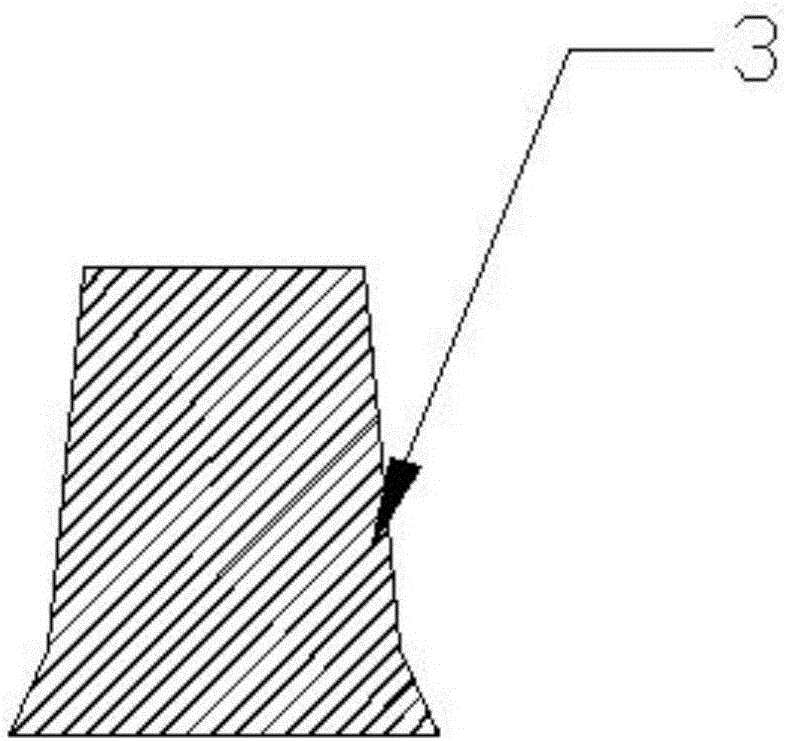

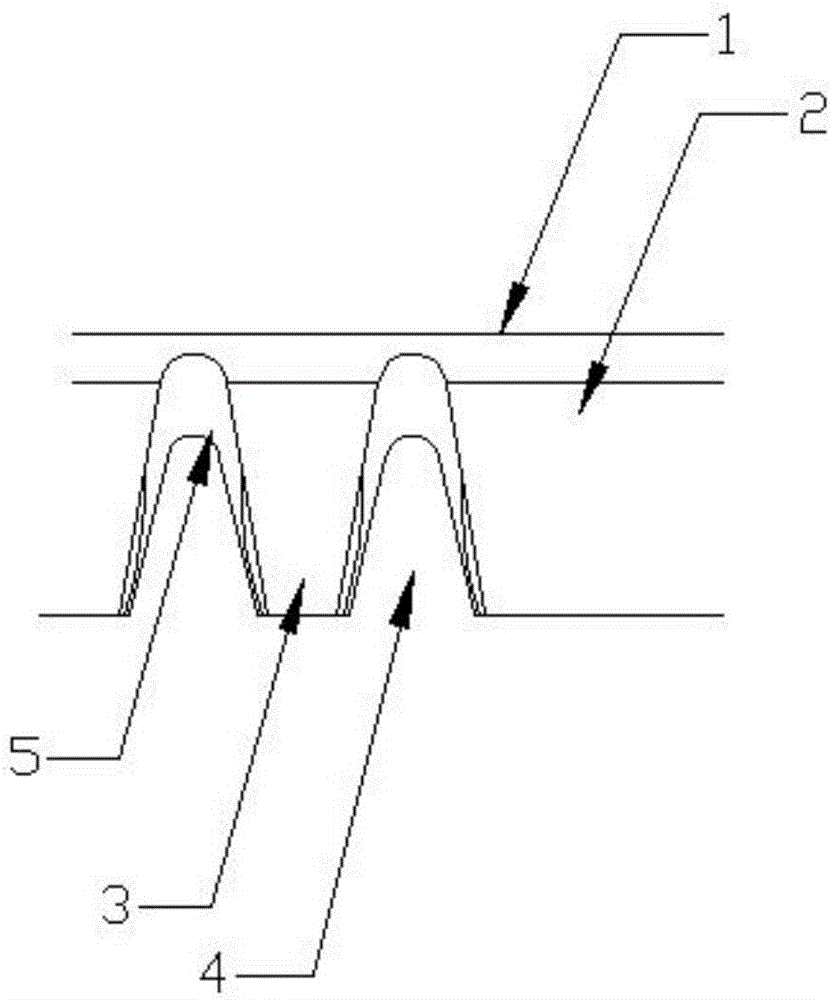

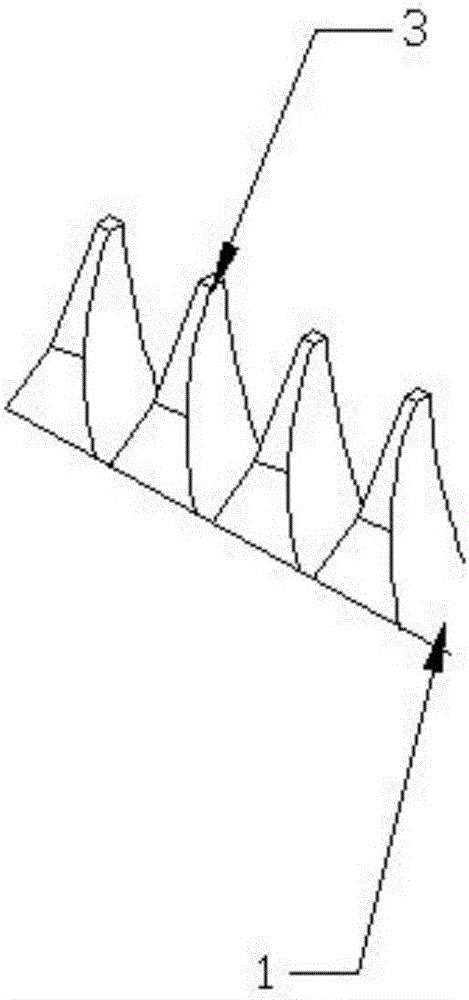

[0024] like Figure 1-4 As shown, the present invention provides a comb-toothed blade structure and method of use, including a blade body 1, the blade body 1 includes a blade plate 2, one side of the blade plate 2 is provided with several blade teeth 3, adjacent blade teeth 3 are provided with a knife-tooth gap 4, and the bottom of the knife-tooth gap 4 is provided with a knife-edge surface 5; the cross-section of the knife-tooth 3 is trapezoidal and the bottom edge of the trapezoid is the knife-edge surface 5; the distance between the knife-tooth gap 4 is from outside to inside slowing shrieking.

[0025] Further, the bottom between the adjacent knife teeth 3 is provided with a concave groove mechanism 6, which reduces the contact area between the movable knife and the fixed knife, reduces the friction force, and thus reduces the heat generated during operation.

[0026] The thickness from the top to the bottom of the knife teeth 3 gradually increases, which enhances the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com