A fault-tolerant control method for MMC systems without redundant sub-modules

A control method and system fault-tolerant technology, which are applied in output power conversion devices, electrical components, and AC power input to DC power output, etc., which can solve the problems of large computational load, cumbersome control, and rarely applied MMC modulation strategies. , to improve the utilization rate, reduce the harmonic content, and improve the effect of three-phase automatic voltage equalization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

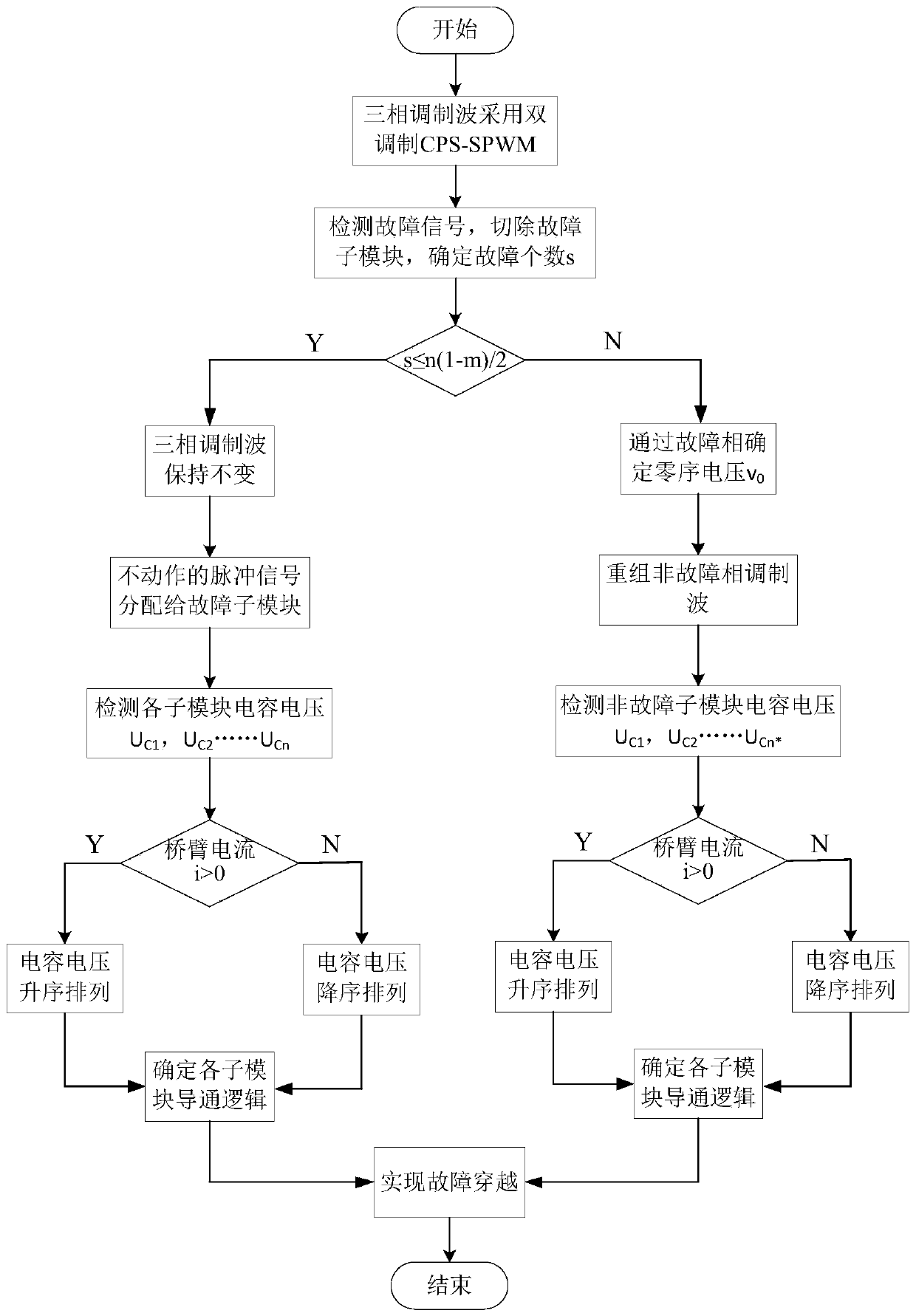

[0054] Such as figure 1 As shown in the flow chart, the implementation steps of a fault-tolerant control method for an MMC system without redundant sub-modules are:

[0055] Step 1: Determine the position of the faulty sub-module according to the result of fault location, cut off the faulty sub-module through the bypass switch, and do nothing for the remaining normal sub-modules;

[0056] Step 2: On the basis of step 1, according to the range of the number s of faulty sub-modules, the three-phase modulation wave is processed accordingly. When s≤n(1-m) / 2, the reference voltage remains unchanged and the non-action The pulse is distributed to the fault sub-module, and the three-phase modulation wave does not need to be recombined at this time; when s>n(1-m)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com