Heat management system and method of cylindrical battery pack

A thermal management system and cylinder technology, applied in the field of thermal management, can solve the problems of being unable to operate in cold areas or cold weather at the same time, low heat dissipation efficiency, long heat dissipation time, etc., and achieve the effects of simple structure, compact size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described below in conjunction with the accompanying drawings.

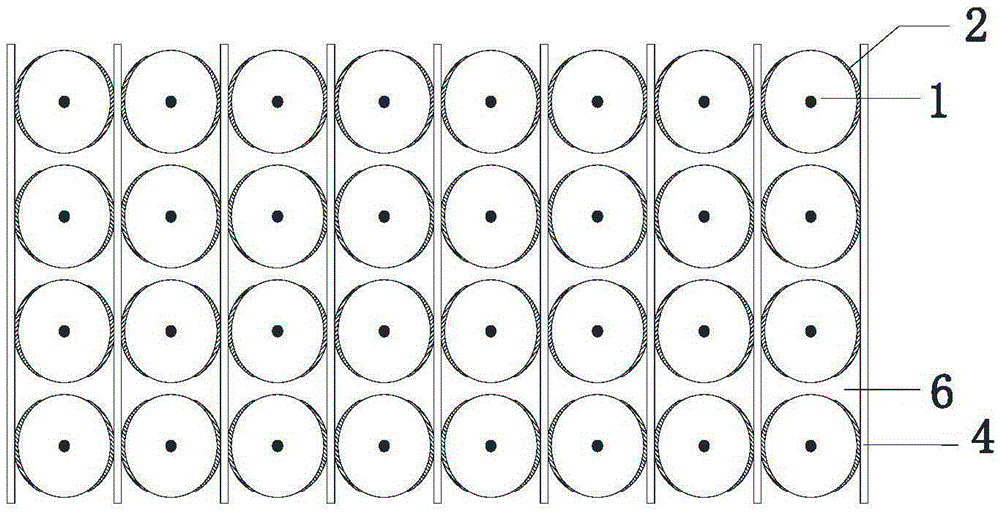

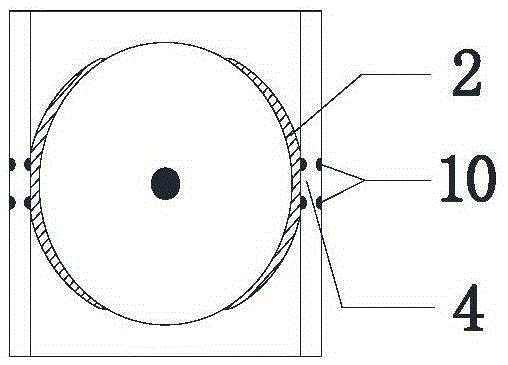

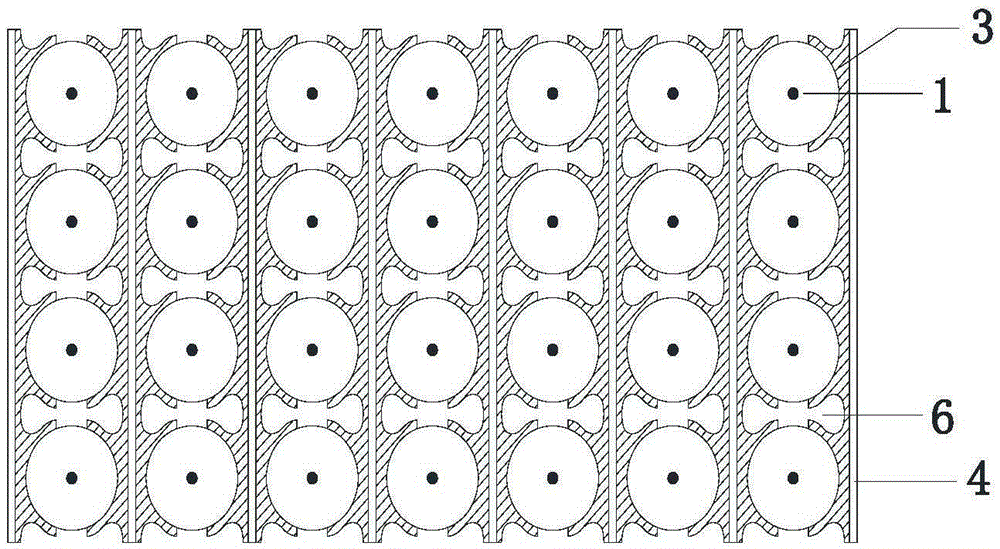

[0034] The invention relates to a thermal management system for a cylindrical battery pack, which includes a special-shaped heat conducting plate, a micro heat pipe array plate and a heat source, wherein the heat source can be an electric heating element or a heated fluid medium (which can be of a temperature higher than that of the battery) Hot fluid medium (such as hot air or hot liquid) pipeline, the electric heating element can be resistance wire or electric heating film; one plate surface of the special-shaped heat conduction plate is an arc-shaped plate surface and is closely attached to the surface of the cylindrical battery through the arc-shaped plate surface The other plate surface on the special-shaped heat conduction plate opposite to the arc-shaped plate surface has a planar structure along the length direction of the plate and is attached to the micro heat pipe ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com