Method for preparing direct alcohol fuel cell graphene-based anode electro-catalyst

A fuel cell, graphene-based technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the interface activity of graphene and nanoparticles, unreliable performance, uneven distribution, etc., and achieve simplified coating preparation Effects of catalyst layer steps, simplified powder structure, and easy battery assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

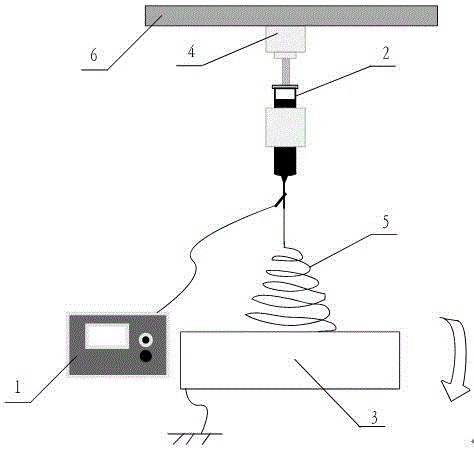

[0027] The preparation method of the PtSn graphene-based anode catalyst with graphene 10mg added in the electrospinning solution:

[0028] Add 10mg of graphene into 9g of N,N-dimethylformamide, ultrasonically disperse for 30 minutes to obtain a uniformly dispersed graphene-DMF mixture, take 0.71g of polyacrylonitrile into the graphene-DMF mixture, and magnetically stir 1h and keep the temperature at 60°C, add 0.115g SnCl 4 • 5H 2 O and 0.34 g of chloroplatinic acid were placed on a magnetic stirrer and continued to stir for 2 h while keeping the temperature at 60° C. until all dissolved and turned into a black sol. The receiving distance is selected as 16cm, the advancing speed is 0.002mm / s, and the voltage of 20kV is applied for electrospinning. The receiving device is a rotating collector plate, the rotating speed range is 1000r / min-1500r / min, and the spinning time is 8h. The anode electrocatalyst membrane spun in this embodiment has a smooth surface, uniform thickness, a...

Embodiment 2

[0030] The preparation method of the PtSn graphene-based anode catalyst with graphene 20mg added in the electrospinning liquid:

[0031] Add 20mg of graphene into 9g of N,N-dimethylformamide, and ultrasonically disperse for 30 minutes to obtain a uniformly dispersed graphene-DMF mixture. Take 0.71g of polyacrylonitrile and put it into the graphene-DMF mixture, and stir it magnetically 1h and keep the temperature at 60°C, add 0.115g SnCl 4 • 5H 2 O and 0.34g of chloroplatinic acid, placed on a magnetic stirrer and continued to stir for 2h and ensured that the temperature was 60°C, until all dissolved and turned into a black sol, the receiving distance was selected as 16cm, the advancing speed was 0.002mm / s, and a voltage of 25kV was applied. Electrospinning, the receiving device is a rotating collector plate, the speed range is 1000r / min-1500r / min, and the spinning time is 8h. The anode electrocatalyst membrane spun in this example has a smooth surface, uniform thickness, and...

Embodiment 3

[0033] The preparation method of the PtSn graphene-based anode catalyst with graphene 50mg added in the electrospinning solution:

[0034] 50 mg of graphene was added into 9 g of N,N-dimethylformamide, and ultrasonically dispersed for 30 min to obtain a uniformly dispersed graphene-DMF mixture. Take 0.71g polyacrylonitrile and put it into the graphene-DMF mixture, stir it magnetically for 1h and keep the temperature at 60°C, add 0.115g SnCl 4 • 5H 2 O and 0.34g of chloroplatinic acid, placed on a magnetic stirrer and continued to stir for 2h and ensured that the temperature was 60°C, until all dissolved and turned into a black sol, the receiving distance was selected as 16cm, the advancing speed was 0.002mm / s, and a voltage of 30kV was applied. Electrospinning, the receiving device is a rotating collector plate, the speed range is 1000r / min-1500r / min, and the spinning time is 8h. The anode electrocatalyst membrane spun in this example has a smooth surface, uniform thickness,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com