A kind of preparation method of low-impurity multi-element precursor

A precursor and low-impurity technology, applied in the direction of electrical components, structural parts, battery electrodes, etc., can solve problems such as damage, increased production costs, and conflicts, and achieve the effects of reducing processing volume, reducing production, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

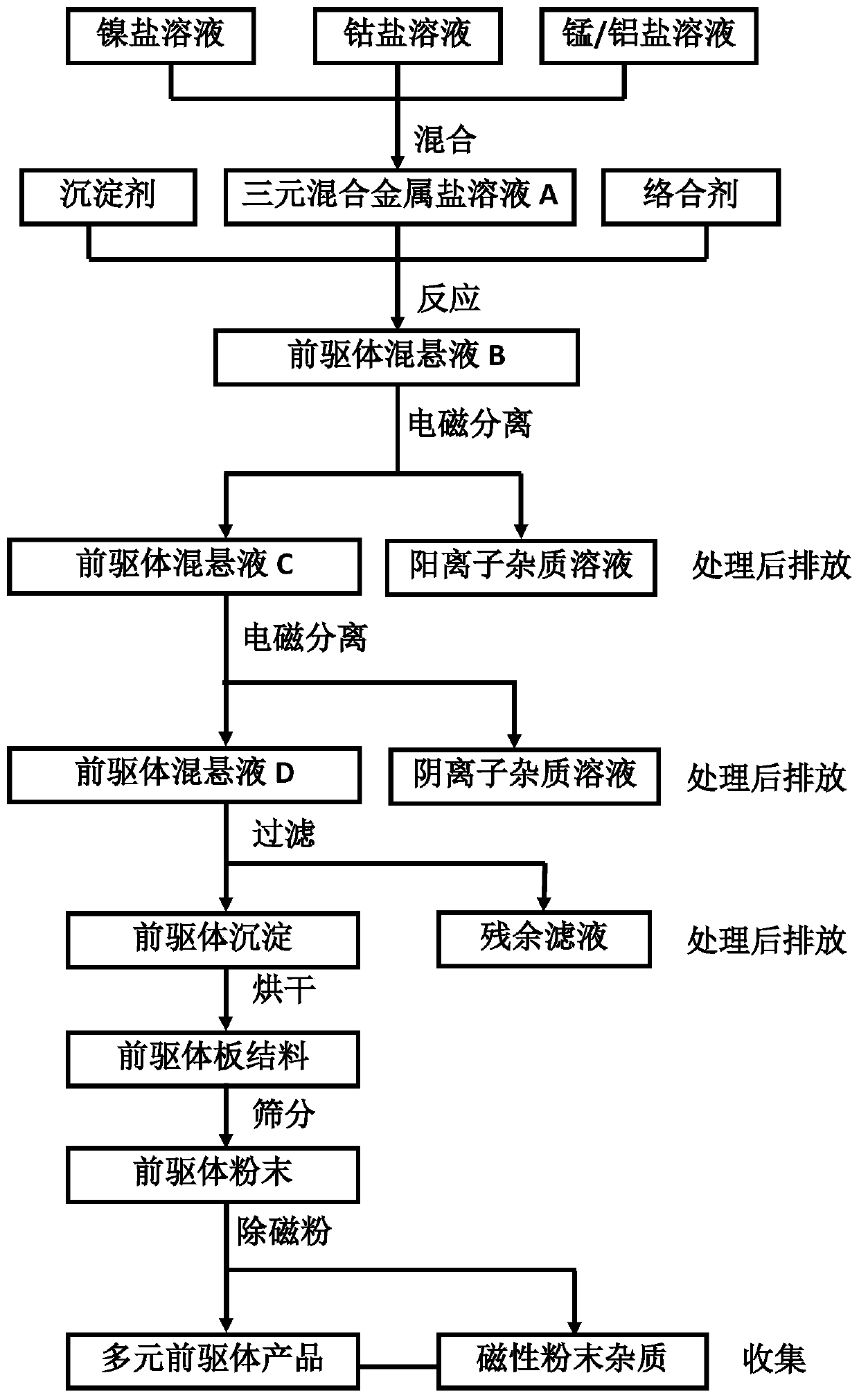

[0047] The preparation method of a kind of low-impurity multi-element precursor of the present invention, such as figure 1 shown, including the following steps;

[0048] (1) Mix the solutions of inorganic salts or organic salts of nickel salt, cobalt salt and manganese / aluminum salt to obtain a ternary mixed metal salt solution A; add a precipitant and a complexing agent in the ternary mixed metal salt solution A, and merge After mixing, the mother liquor is obtained, and the mother liquor is added to the reactor, stirred with a stirring paddle, reacted, nucleated, grown and aged, the reaction, nucleated, grown and aged time is 10-30h, and the pH of the reactor is controlled at 10.5 -13.5, the reaction temperature is controlled at 40-80°C to obtain precursor suspension B;

[0049] Wherein, the concentration of the ternary mixed metal salt solution A is 0.5-2.5mol / L, the concentration of the precipitating agent is 1-3mol / L, and the concentration of the complexing agent is 0.5-...

Embodiment 1

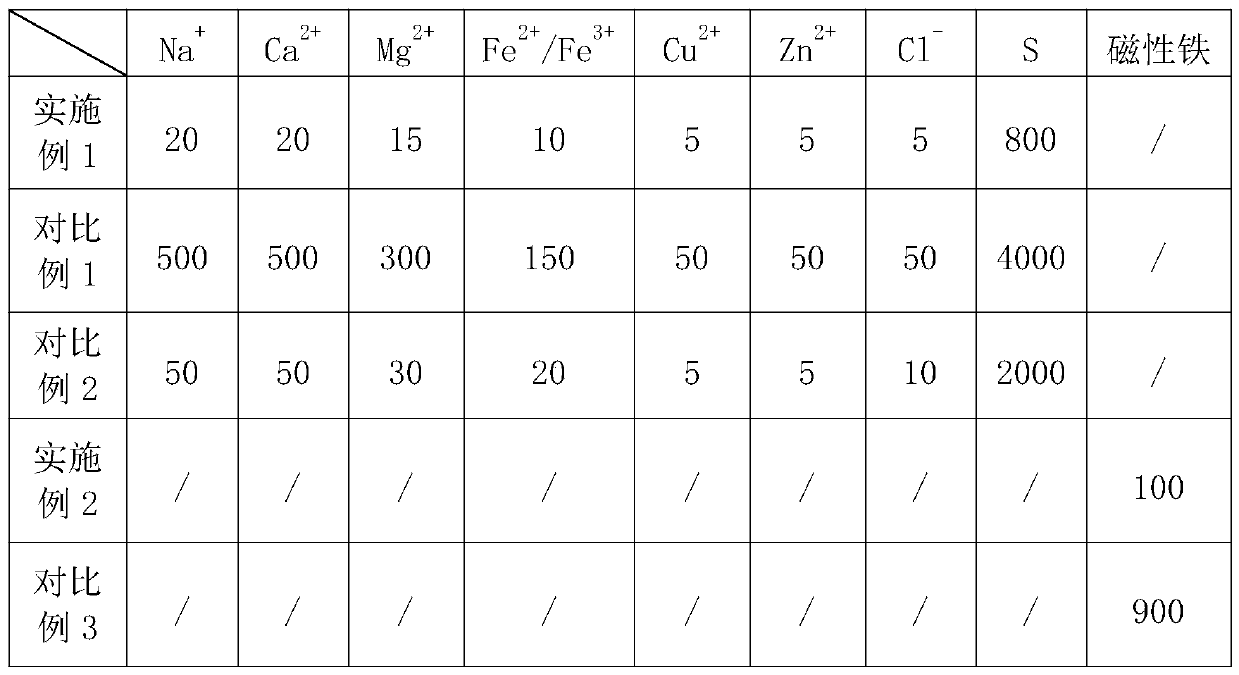

[0065] Put nickel, cobalt, manganese / aluminum sulfate mixed solution A, sodium hydroxide solution, and ammonia solution into the reaction kettle with double-layer inner cylinder structure at the same time and stir. The materials stay in the reaction kettle at 50°C for 15 hours, and the solution The pH value is 11.0, all the suspension is introduced into the electromagnetic separation tank, the separation tank is turned on for stirring, and the excitation is turned on to 2000 Oe. After 20 minutes, the solution containing impurity cations is extracted, and deionized water is continuously replenished at the same flow rate as the pumping solution. Continue to stir the ternary precursor suspension after separating impurity cations, turn on the separation tank for stirring, turn on the excitation to 2000Oe, and pump out the solution containing impurity anions for 20 minutes, and continuously replenish deionized water at the same flow rate as the pumping liquid. Filter, dry and sieve ...

Embodiment 2

[0067] Put nickel, cobalt, manganese / aluminum sulfate mixed solution A, sodium hydroxide solution, and ammonia solution into the reaction kettle with double-layer inner cylinder structure at the same time and stir. The materials stay in the reaction kettle at 50°C for 15 hours, and the solution The pH value is 11.0, all the suspension is introduced into the electromagnetic separation tank, the separation tank is turned on for stirring, and the excitation is turned on to 2000 Oe. After 20 minutes, the solution containing impurity cations is extracted, and deionized water is continuously replenished at the same flow rate as the pumping solution. Continue to stir the ternary precursor suspension after separating impurity cations, turn on the electromagnetic separation tank for stirring, turn on the excitation to 2000Oe, and pump out the solution containing impurity anions for 20 minutes, and continuously replenish deionized water at the same flow rate as the pumping liquid. Filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com