Vanadium oxide/carbon nanotube flexible film as well as preparation method and application thereof

A technology of vanadium oxide and carbon nanotubes, which is applied in the field of nanomaterials and electrochemistry, can solve the unreported problems of vanadium oxide/carbon nanotube flexible thin film electrodes, and achieve excellent cycle stability, excellent rate performance, and equipment requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

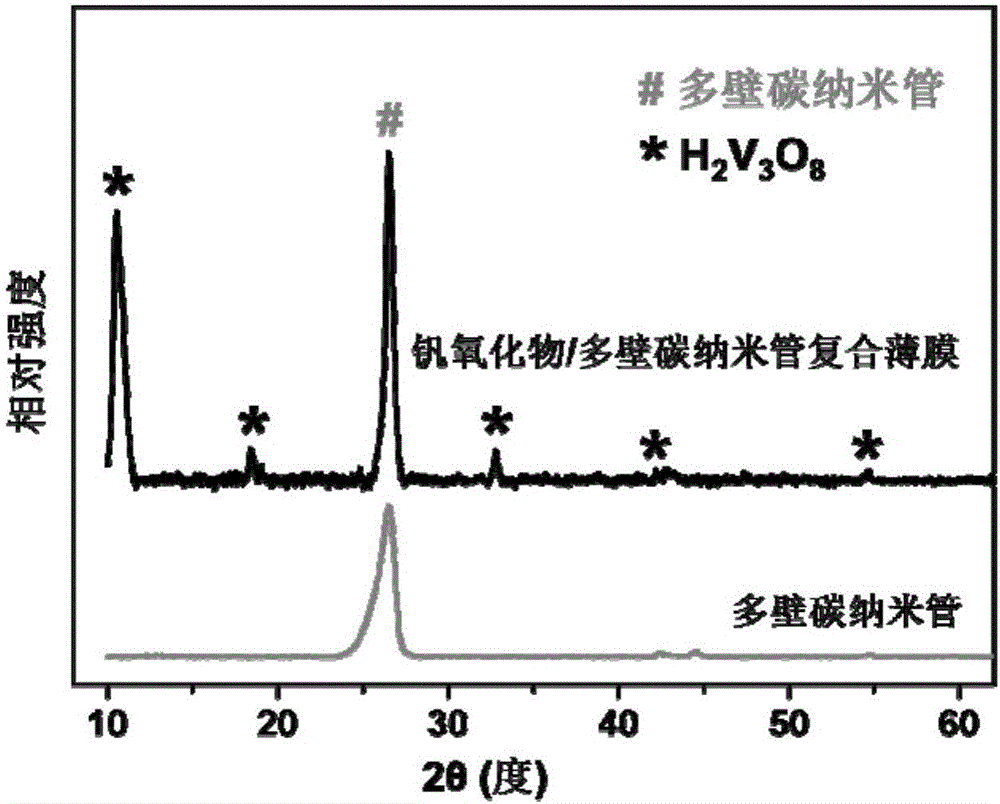

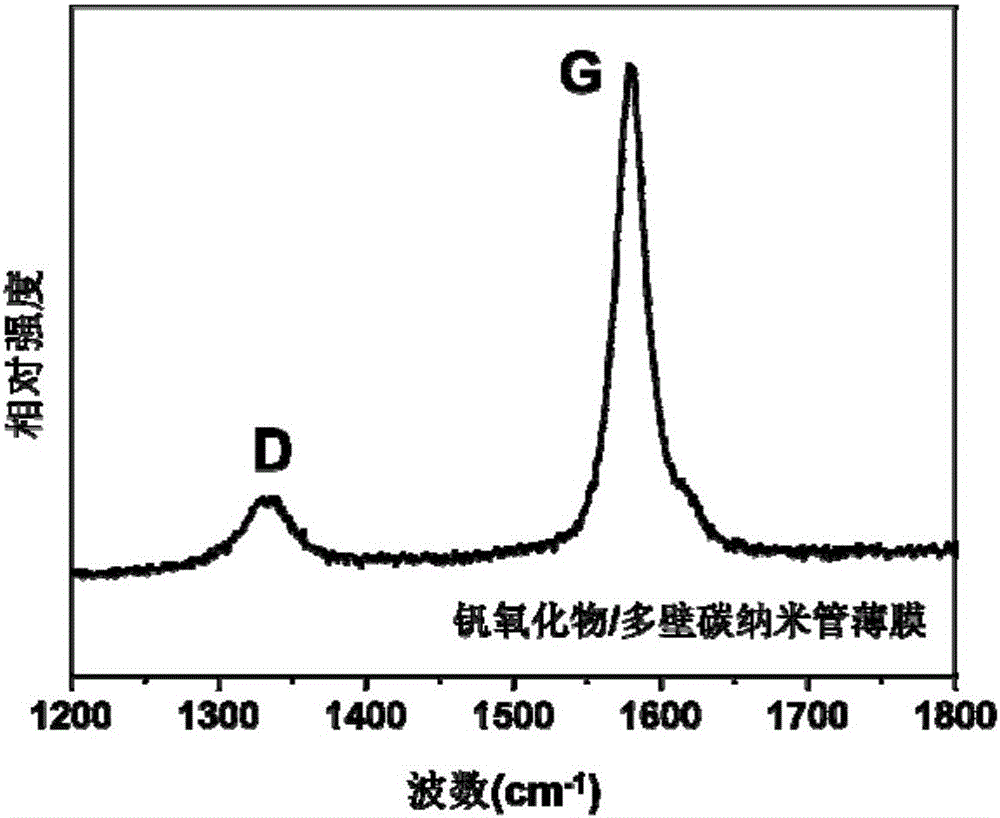

[0031] A method for preparing a vanadium oxide / carbon nanotube flexible film, which comprises the following steps:

[0032] 1) Weigh 17mg of polyvinylpyrrolidone (PVP, K30) and 0.1mmol LiCO 3 Dissolve in 30mL deionized water;

[0033] 2) Add 100 mg of multi-walled carbon nanotubes to the solution obtained in step 1), and ultrasonically disperse for 1 hour;

[0034] 3) Add 1.5 mmol vanadium pentoxide sol with a volume of 30 mL to the solution obtained in step 2), continue stirring for 1 hour, and ultrasonically disperse for 1 hour;

[0035] 4) Transfer the solution obtained in step 3) into a 100mL reaction kettle, and react in an oven at 160°C for 96 hours; take out the reaction kettle, and naturally cool to room temperature;

[0036] 5) After fully stirring and breaking up the product obtained in step 4), use a mixed cellulose filter membrane with a pore size of 0.45 μm as a suction filter paper, and take 5 mL of hydrogel for suction filtration;

[0037] 6) Dry the filter m...

Embodiment 2

[0043] A method for preparing a vanadium oxide / carbon nanotube flexible film, which comprises the following steps:

[0044] 1) Weigh 17mg of polyvinylpyrrolidone (PVP, K30) and 0.2mmol LiCO 3 Dissolve in 30mL deionized water;

[0045] 2) Add 150 mg of multi-walled carbon nanotubes to the solution obtained in step 1), and ultrasonically disperse for 1 hour;

[0046] 3) Add 1.5 mmol vanadium pentoxide sol with a volume of 30 mL to the solution obtained in step 2), continue stirring for 1 hour, and ultrasonically disperse for 1 hour;

[0047] 4) Transfer the solution obtained in step 3) into a 100mL reactor, and react in an oven at 200°C for 120 hours; take out the reactor, and cool it down to room temperature naturally;

[0048] 5) After fully stirring and breaking up the product obtained in step 4), use a mixed cellulose filter membrane with a pore size of 0.10 μm as a suction filter paper, and take 5 mL of hydrogel for suction filtration;

[0049] 6) Dry the filter membrane...

Embodiment 3

[0054] A method for preparing a vanadium oxide / carbon nanotube flexible film, which comprises the following steps:

[0055] 1) Weigh 17mg of polyvinylpyrrolidone (PVP, K30) and 0.1mmol LiCO 3 Dissolve in 30mL deionized water;

[0056] 2) Add 150 mg of multi-walled carbon nanotubes to the solution obtained in step 1), and ultrasonically disperse for 1 hour;

[0057] 3) Add 1.5 mmol vanadium pentoxide sol with a volume of 30 mL to the solution obtained in step 2), continue stirring for 1 hour, and ultrasonically disperse for 1 hour;

[0058] 4) Transfer the solution obtained in step 3) into a 100mL reactor, and react in an oven at 180°C for 108 hours; take out the reactor, and cool it down to room temperature naturally;

[0059] 5) After fully stirring and breaking up the product obtained in step 4), use a mixed cellulose filter membrane with a pore size of 0.45 μm as a suction filter paper, and take 10 mL of hydrogel for suction filtration;

[0060] 6) Dry the filter membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com