Auxiliary interconnection in special-shaped arcs Silver-gated oblique hooks Cathode structure light-emitting display with concave tire surface

A technology of a light-emitting display and a cathode structure, which is applied in the fields of science and technology and the intersection of vacuum science and technology, and can solve the problems of inability to adapt to the market demand of display technology, failure of field emission light-emitting displays, and vulnerability to damage and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to this embodiment.

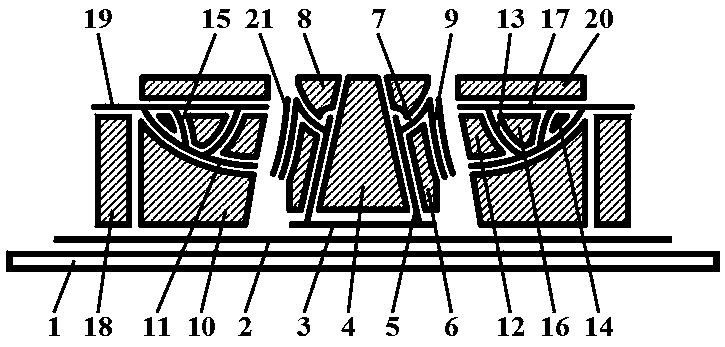

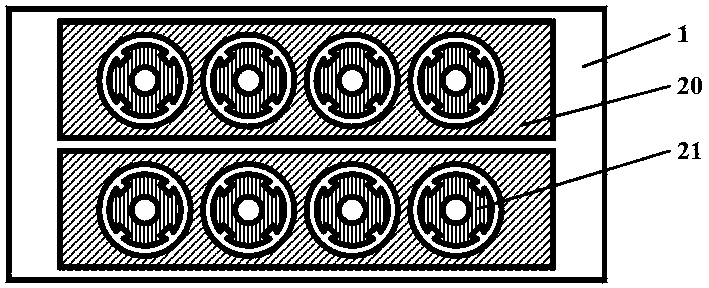

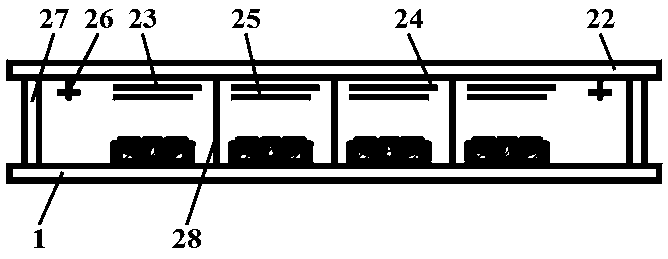

[0051] The light-emitting display of the special-shaped arc internal auxiliary interconnection silver-gated oblique hook concave tire surface cathode structure in this embodiment is as follows: figure 1 , figure 2 and image 3 As shown, it includes a vacuum chamber composed of an upper compression-resistant flat white glass cover plate 22, a lower compression-resistant flat white glass cover plate 1 and a transparent glass frame 27; an anodic oxide transparent square film is arranged on the upper compression-resistant flat white glass cover plate 22 Layer 23, the anode extended wide curved silver layer 24 connected to the anodic oxide transparent square film layer 23 and the phosphor layer 25 prepared on the anodic oxide transparent square film layer 23; Auxiliary interconnection within the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com