Diamond circular saw web design and sawing process parameter setting method

A technology of process parameters and circular saw blades, which is applied in the field of design of diamond circular saw blades and formulation of sawing process parameters, can solve the problems of related theoretical research not being transformed into practical operation basis and guidance methods, surface processing quality reduction, diamond circular saw Chip damage and other problems, to optimize the structural size and processing parameters, avoid resonance, reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

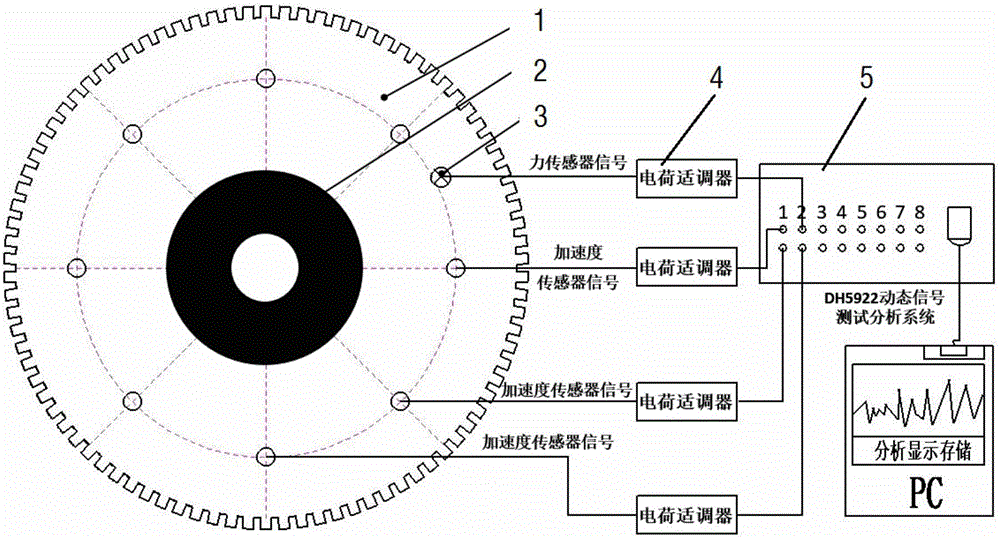

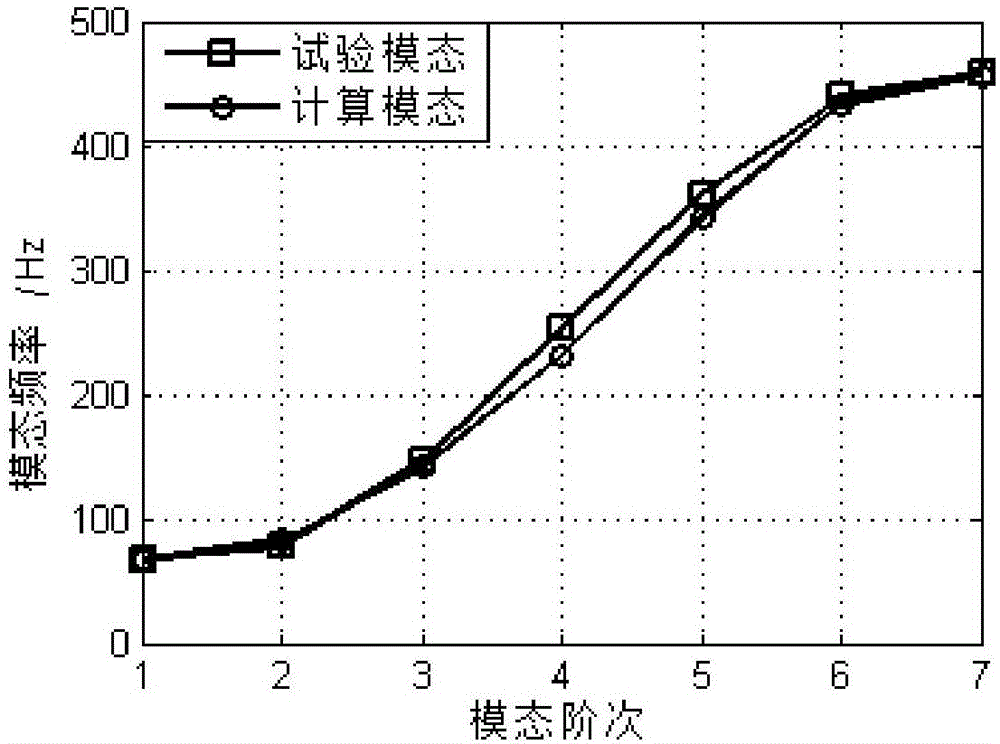

[0040] Embodiment 1: The present invention provides a kind of diamond circular saw blade design and the formulating method of sawing process parameter, first use modal experiment to verify the reliability of modal simulation analysis method:

[0041] ⑴. Taking a piece of ordinary diamond circular saw blade 1 with a diameter of Φ400mm as the test piece, conduct a constraint modal experimental analysis on it. For the experimental schematic diagram, see figure 1 , the chuck 2 with a diameter of Φ100mm is used for clamping and restraint. Various measuring sensors 3 are placed on the diamond circular saw blade 1, including force sensors and multiple acceleration sensors, and the signals received by each sensor are respectively passed through the charge adapter. 4 is sent to the signal test and analysis system 5, through the analysis and processing of the experimental data, after the experiment, the modal frequencies of each order of the diamond circular saw blade 1 can be obtained. ...

Embodiment 2

[0086] Embodiment 2: the diamond circular saw blade design provided by the present invention and the formulation method of sawing process parameters are applied to actual production, and the selection of diamond circular saw blades and the formulation of sawing process parameters are carried out, specifically as follows:

[0087] Assuming that the stone to be processed in actual production is granite, if the linear cutting speed of the diamond circular saw blade is pre-selected as 25m / s, the cutting depth of the stone is 120mm, and the clamping diameter ratio is 0.4. Considering the size of the chuck, the circular saw blade The cutting depth should be greater than 120mm, according to the calculation formula of the maximum cutting depth of the circular saw blade: 0.5×(D-0.4D)>120; therefore, the diameter of the diamond circular saw blade should be greater than 400mm.

[0088] According to the specifications of diamond circular saw blades, the specifications of circular saw blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com