Oxygen-carbon ratio control system and gasifier oxygen-coal ratio control method thereof

A control method and technology for a control system, which are applied to the oxygen-carbon ratio control system and the oxygen-coal ratio control field of a gasifier, can solve problems such as hidden safety hazards, device shutdown, immature control theory and application, and achieve optimal automatic control. , to ensure safe and reliable operation, and to promote the effect of large-scale application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

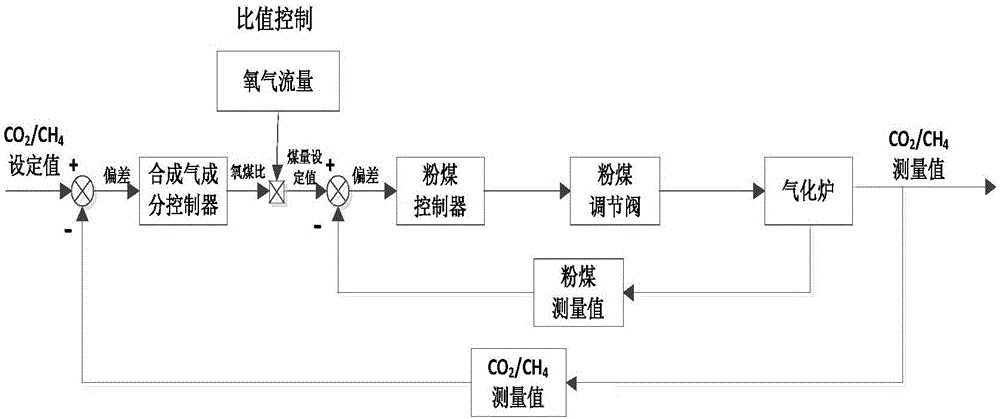

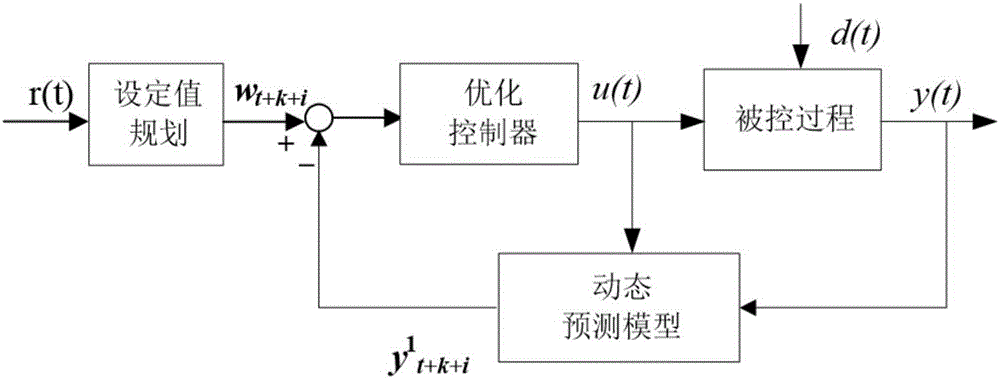

[0034] An oxygen to carbon ratio control system such as figure 1 As shown, it includes a cascade loop with syngas composition as the controlled variable. The cascade loop includes a main loop and a secondary loop. The primary loop includes a main loop controller, and the secondary loop is a pulverized coal flow regulating loop; Synthesizer composition controller, secondary loop includes pulverized coal controller; synthesizer composition controller is connected with pulverized coal controller, and pulverized coal controller is also connected with pulverized coal regulating valve, pulverized coal pipeline and gasifier in turn; The gas composition controller is controlled by the predictive controller; in the oxygen-carbon ratio control system, the oxygen flow rate is determined by the gasifier load, and the syngas composition controller determines the oxygen-coal ratio according to the measured syngas composition, and then multiplied by the oxygen flow rate , and then get the se...

Embodiment 2

[0036] A gasifier oxygen-coal ratio control method, such as Figure 1 to Figure 3 As shown, adopt the oxygen-carbon ratio control system described in embodiment 1, comprise the following steps:

[0037] The first step is system modeling: using the recursive augmented least squares method with forgetting factor, the pulverized coal regulating circuit and gasifier are taken as the whole object for model identification;

[0038] In the second step, the syngas is controlled using a predictive control algorithm.

Embodiment 3

[0040] A gasifier oxygen-coal ratio control method is similar to Embodiment 2, the difference is that in the first step, the system modeling includes the following steps: First, the combination of limiting filtering and recursive average filtering method is selected The data preprocessing method is used to preprocess the data; secondly, the method of maximum and minimum is used for normalization processing; thirdly, the recursive augmented least square method with forgetting factor is used for system identification; then, the model is judged according to the average value error Convergence; finally, model simulation and validation.

[0041] It should be noted that the gasifier oxygen-coal ratio control method of the present invention:

[0042] (1) Limiting filter: According to empirical judgment, determine the maximum deviation value allowed for two samplings (set to A), and judge each time a new value is detected: if the difference between this value and the previous value ≤ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com