Aspheric surface paperweight magnifying lens and manufacturing method thereof

A technology of aspheric lens and magnifying glass, which is applied in the field of aspheric paperweight magnifying glass and its preparation, can solve the problems of complex structure, light weight, addition, etc., and achieve the effects of large observation range, large magnification and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] A preparation method of an aspheric paperweight magnifying glass, comprising the steps of:

[0015] Step 1: Use ZJP0.5 hem fine grinding and polishing machine and SPCM-M1 centering edging machine to cold process the aspheric lens blank until it meets the appearance inspection standard of MIL40-20, and the aspheric lens blank is an aspheric surface magnifying glass lens 1;

[0016] Step 2: The metal ferrule 2 is processed by a single-point car-type integrated non-marking processing method. After processing, the inner diameter of the metal ferrule is equal to the outer diameter of the aspheric magnifying glass lens 1;

[0017] Step 3: Use a muffle furnace to heat the metal ferrule 2 processed in step 2, heat the metal ferrule 2 to 580-620°C, and use the principle of thermal expansion and contraction to make the inner diameter of the metal ferrule 2 expand when heated Heat preservation is carried out when the expansion is 0.8mm to 1.2mm, and the aspheric magnifying glass ...

Embodiment 1

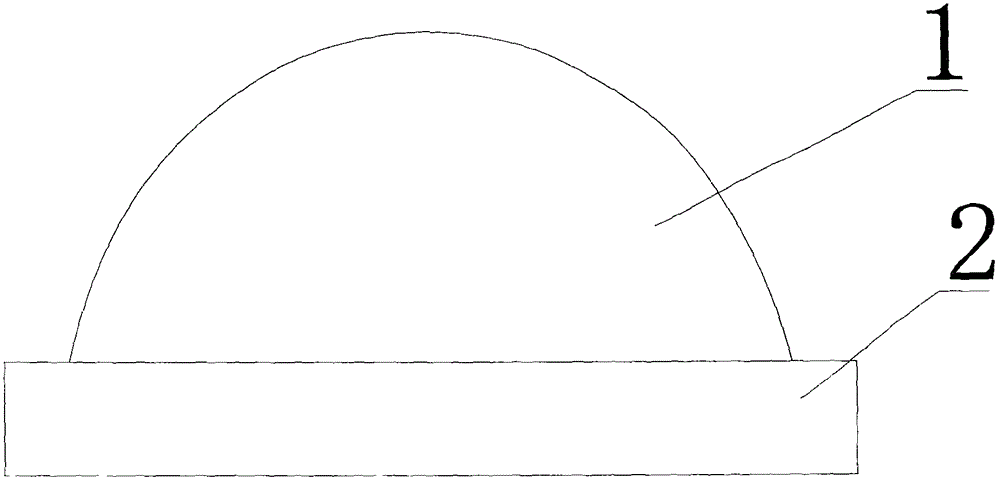

[0022] An aspheric paperweight magnifying glass comprises an aspheric magnifying glass lens 1 and a metal ferrule 2 arranged outside the aspheric magnifying glass lens 1 , the outer diameter of the aspheric magnifying glass lens 1 is equal to the inner diameter of the metal ferrule 2 . The aspheric magnifying glass lens 1 is clamped inside the metal ferrule 2 . The metal ferrule 2 is made of food grade 304 stainless steel.

[0023] A preparation method of an aspheric paperweight magnifying glass, comprising the steps of:

[0024] Step 1: Use ZJP0.5 hem fine grinding and polishing machine and SPCM-M1 centering edging machine to cold process the aspheric lens blank until it meets the appearance inspection standard of MIL40-20, and the aspheric lens blank is an aspheric surface magnifying glass lens 1;

[0025] Step 2: The metal ferrule 2 is processed by a single-point car-type integrated non-marking processing method. After processing, the inner diameter of the metal ferrule i...

Embodiment 2

[0029] An aspheric paperweight magnifying glass comprises an aspheric magnifying glass lens 1 and a metal ferrule 2 arranged outside the aspheric magnifying glass lens 1 , the outer diameter of the aspheric magnifying glass lens 1 is equal to the inner diameter of the metal ferrule 2 . The aspheric magnifying glass lens 1 is clamped inside the metal ferrule 2 . The metal ferrule 2 is made of food grade 304 stainless steel.

[0030] A preparation method of an aspheric paperweight magnifying glass, comprising the steps of:

[0031] Step 1: Use ZJP0.5 hem fine grinding and polishing machine and SPCM-M1 centering edging machine to cold process the aspheric lens blank until it meets the appearance inspection standard of MIL40-20, and the aspheric lens blank is an aspheric surface magnifying glass lens 1;

[0032] Step 2: The metal ferrule 2 is processed by a single-point car-type integrated non-marking processing method. After processing, the inner diameter of the metal ferrule i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com