Small-capacity contactor electrical endurance test system and method

A test system and contactor technology, applied in the direction of circuit breaker testing, etc., can solve the problems of insufficient isolation, slow operation speed, and inability to more accurately judge the failure of contactor test products, so as to improve accuracy and test accuracy , the effect of a good man-machine interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

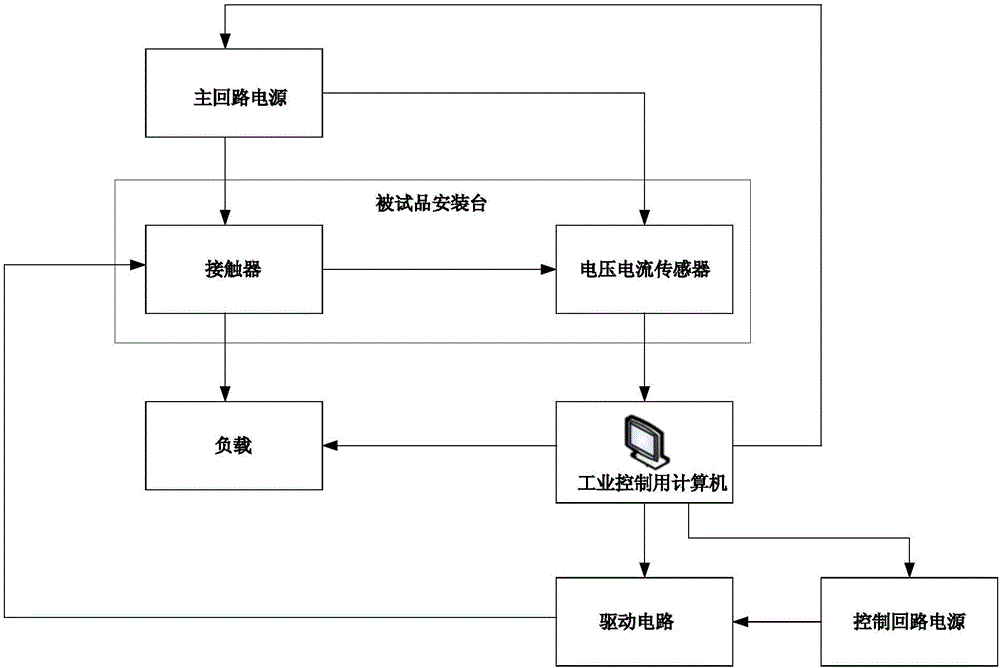

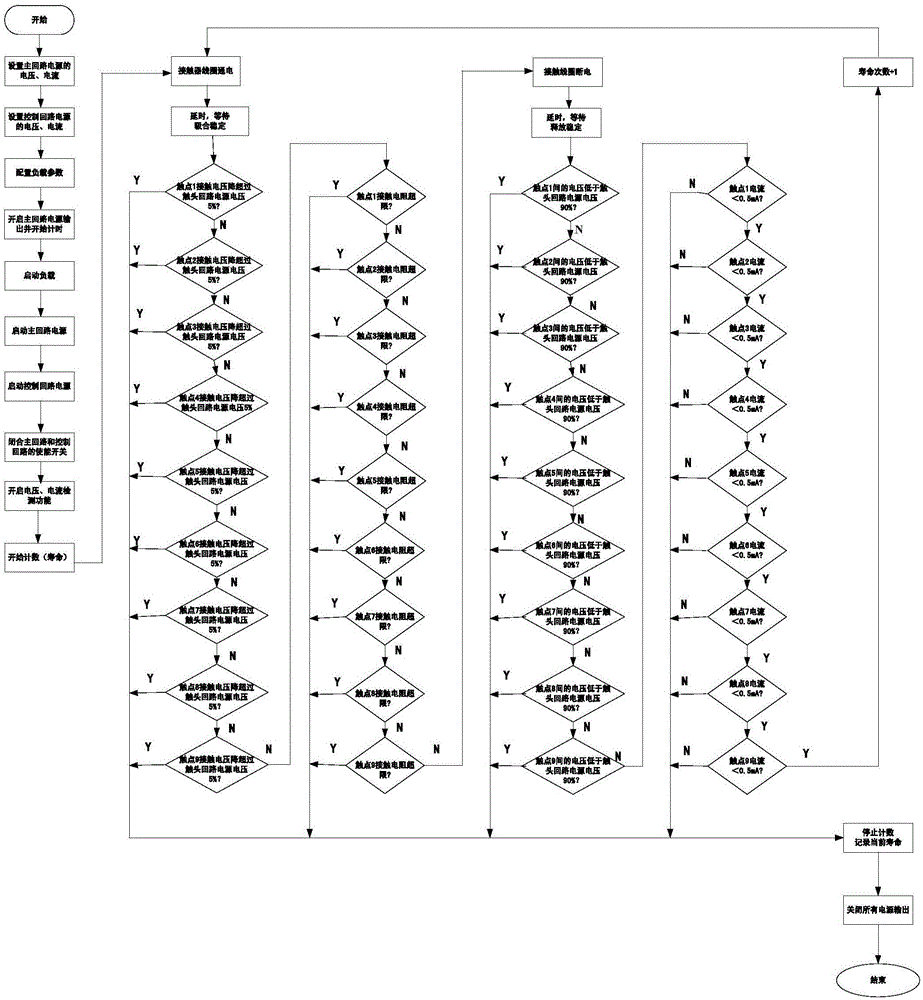

[0015] refer to figure 1 , the present invention includes a control loop power supply, a main loop power supply, an industrial computer, a drive circuit, a load, and a voltage and current sensor. The contactor is installed on the installation platform of the tested product, and the terminals of the voltage sensor and current sensor in the test system are installed on the back panel inside the test product installation platform. Each test can be connected to the signal line according to the needs of the test project. Specifies the terminal. The test product installation platform mainly integrates all power output and load input interfaces, and at the same time integrates voltage sensors, current sensors, temperature sensors, humidity sensors, etc. for system testing needs. There are two types of loads: manual and intelligent. There is a control circuit inside the load, a contactor and a communication device inside; the industrial control machine is connected to the voltage and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com