Low-power working method of MEMS (micro-electromechanical system) metal oxide semiconductor gas sensor

A technology of oxide semiconductors and gas sensors, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of large performance attenuation, decreased sensitivity, difficult to accurately measure low-concentration harmful gases, etc., and achieve low power consumption and warm-up time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

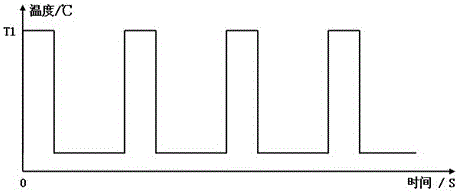

[0030] combined with image 3 Describe this embodiment, the low power consumption working mode of a kind of MEMS metal oxide semiconductor gas sensor described in this embodiment, the specific implementation steps of this method are:

[0031] Step 1. According to the characteristics of the sensor, preheat the sensor at 300°C for 15 minutes in DC for the first time, make its sensitive resistance reach a stable state in a clean air state, and perform a baseline automatic calibration test;

[0032] Step 2. The sensor adopts low-frequency low-duty-cycle cycle heating standby, with DC heating at 300°C for 1 second per cycle, and the heating cycle is 100 seconds;

[0033] Step 3. Preheat the sensor at 300°C for 2 minutes at 300°C for a short time every 4 hours according to the specified cycle, and perform the baseline automatic calibration test after the preheating is completed;

[0034] Step 4: Enter the low-frequency low-duty cycle cycle heating standby again, and execute steps 2...

Embodiment 2

[0037] combined with image 3 Describe this embodiment, the low power consumption working mode of a kind of MEMS metal oxide semiconductor gas sensor described in this embodiment, the specific implementation steps of this method are:

[0038] Step 1. According to the characteristics of the sensor, preheat the sensor at 300°C for 10 minutes with high-frequency PWM (frequency 10kHz) for the first time, make its sensitive resistance reach a stable state in a clean air state, and perform a baseline automatic calibration test;

[0039] Step 2. The sensor adopts low-frequency low-duty-cycle cycle heating standby, and the high-frequency PWM (frequency is 10kHz) heats at 300°C for 1 second per cycle, and the heating cycle is once every 180 seconds;

[0040] Step 3. Preheat the sensor at 300°C for 1 minute with short-term high-frequency PWM (frequency 10kHz) every 3 hours according to the specified cycle, and perform the baseline automatic calibration test after the preheating is compl...

Embodiment 3

[0044] combined with Figure 4 Describe this embodiment, the low power consumption working mode of a kind of MEMS metal oxide semiconductor gas sensor described in this embodiment, the specific implementation steps of this method are:

[0045] Step 1. According to the characteristics of the sensor, preheat the sensor at 300°C for 15 minutes in DC for the first time, make its sensitive resistance reach a stable state in a clean air state, and perform a baseline automatic calibration test;

[0046] Step 2: The sensor adopts low-frequency low-duty cycle cycle heating standby, DC heating at 300°C for 1 second per cycle, low temperature heating at 40°C for 99 seconds, and a heating cycle of 100 seconds;

[0047] Step 3. Preheat the sensor at 300°C for a short period of time according to the specified cycle for 2 minutes. After the preheating is completed, perform the baseline automatic calibration test;

[0048] Step 4: Enter the low-frequency low-duty cycle cycle heating standby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com