High-curvature well section pipe string passing capacity simulation experimental device and its experimental method

A technology for simulating experimental devices and strings, applied to measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as the inability to simulate the ability of strings to be lowered and passed through high-curvature well sections, and achieve structural Ingenious design, easy to transport, and conducive to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

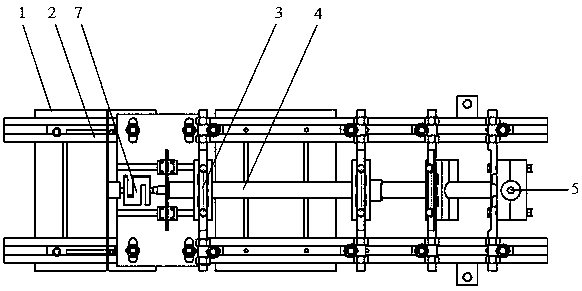

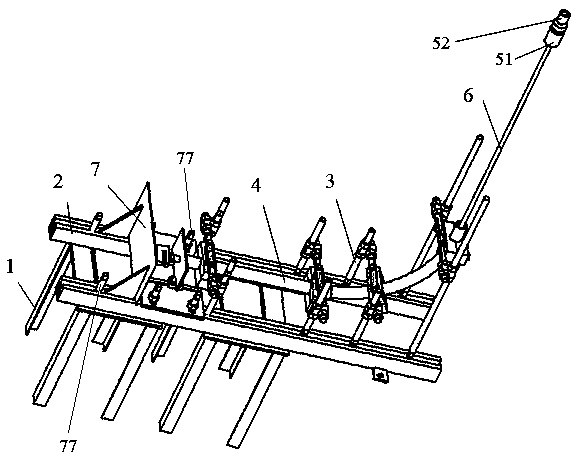

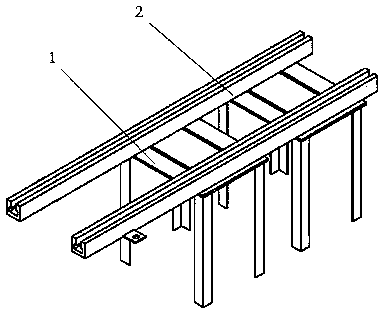

[0045] combine figure 1 , figure 2 As shown, this high-curvature well section pipe string passing capacity simulation experiment device includes a main base 1, multiple sets of fastening devices 3, an outer pipe 4, a baffle set 7, a loading device 5, a pipe string test piece 6, and a main base 1 The first guide rail 2 is arranged on the top, and the outer pipe 4 is connected into one body by the straight pipe section 41 and the bent pipe section 42 through the joint 43. The straight pipe section 41, the bent pipe section 42, and the joint 43 of the outer pipe 4 are all made of transparent organic glass. , it is convenient to observe the state of the string test piece 6. One end of the straight pipe section 41 of the outer pipe 4 is connected to the sliding baffle plate 72 of the baffle plate group 7, the pipe string test piece 6 extends from one end of the bent pipe section 42 of the outer pipe 4, and the other end of the pipe string test piece 6 is connected to the loading ...

Embodiment 2

[0060] In this embodiment, a spacer 79 is provided between the pipe clip and the joint 43, and the spacer 79 is also separate, and each half body has an arc-shaped convex rib, and the pipe clip base 36 and the fixing block 37 have arc-shaped grooves respectively. , one half body is fastened with the pipe clip base 36, and the other half body is fastened with the fixing block 37, and other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com