High-pressure rubber hose detection equipment for mining

A rubber hose and detection equipment technology, applied in the direction of applying stable tension/pressure to test the strength of materials, using liquid/vacuum degree to measure liquid tightness, measuring devices, etc., can solve the problem of pipe explosion, injury to people, hose Assembly pinhole injury and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

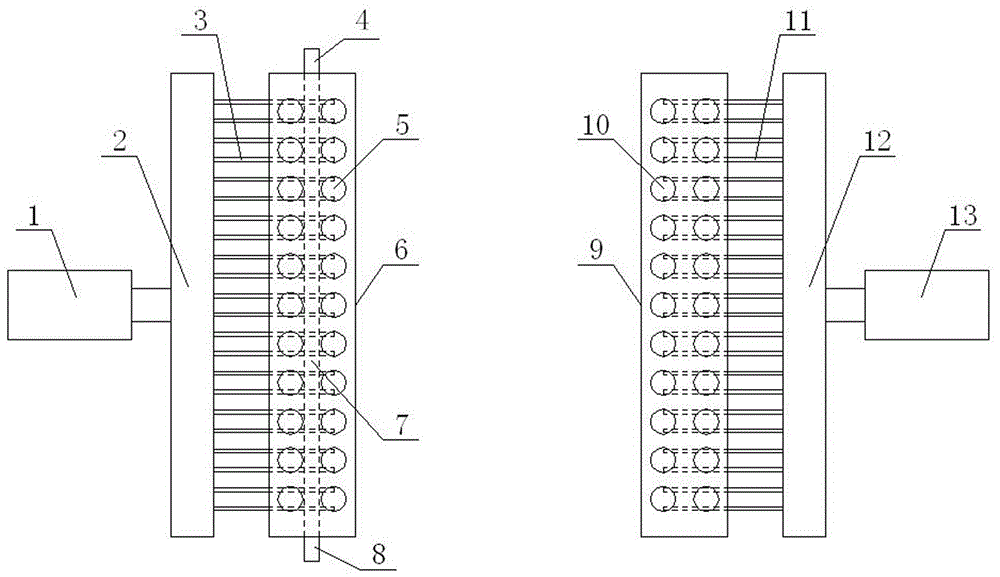

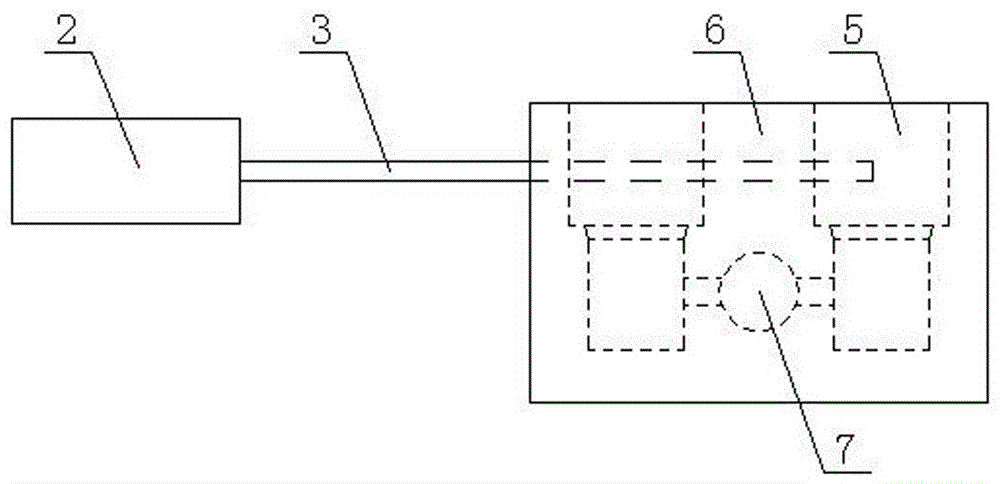

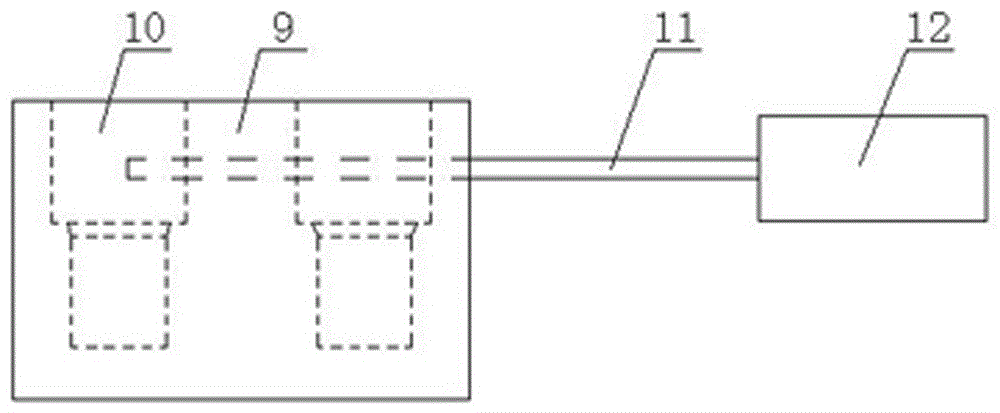

[0012] Such as figure 1 , figure 2 and image 3 As shown, the present invention is used for the detection of high pressure resistance and air tightness of the high pressure rubber hose. The high pressure rubber hose assembly includes a high pressure rubber hose and connectors connected to both ends of the high pressure rubber hose, which includes a main valve block 6 and the auxiliary valve block 9, the main valve block 6 and the auxiliary valve block 9 are in the shape of a cuboid, and the tops of the main valve block 6 and the auxiliary valve block 9 are arranged in a horizontal and vertical array to connect with the joints of the high-pressure rubber hose. The matched mounting holes 5 and 10 are provided with U-shaped card slots corresponding to the mounting holes 5 and 10 in the same row on the sides of the main valve block 6 and the auxiliary valve block 9; bes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com