A Simple Water Level Monitoring System for Jacket Boiler

A technology of water level monitoring and water jacket furnace, applied in the direction of buoy liquid level indicator, etc., can solve the problems of no forming, burnt water jacket, and even oil circuit coils, etc., to reduce "dry burning, easy installation and easy disassembly". Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

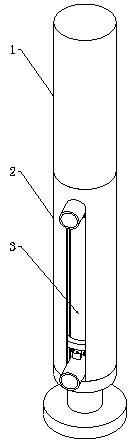

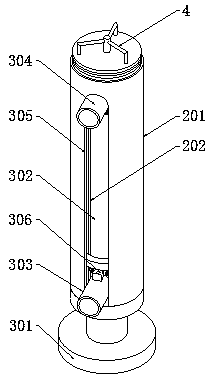

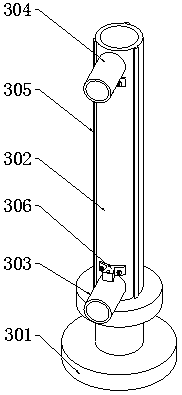

[0033] see figure 1 with figure 2 , the present invention is a simple water level monitoring system for jacket boilers, which includes a floating ball cylinder 3, a floating ball frame 4 and a sleeve 2 arranged outside the floating ball cylinder 3; see image 3 , the float cylinder 3 includes a base 301 and a float cylinder 302 arranged on the base 301 and closed at both ends, two connecting pipes are symmetrically arranged on the side walls of the float cylinder 302 near the two ends; the two communicating pipes pass through The flange is fixedly connected to the water jacket furnace; the upper and lower connecting pipes (upper connecting pipe 304 and lower connecting pipe 303) are arranged to ensure the connection of the water body, and at the same time ensure that the air pressure in the floating ball cylinder 3 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com