A system and method for on-line autonomous measurement of electrolyzer liquid level based on impedance change

A technology of impedance change and measurement method, which is applied in the direction of liquid level indicator for physical variable measurement, and can solve problems such as low efficiency, interference of moving mechanism, and large subjective error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

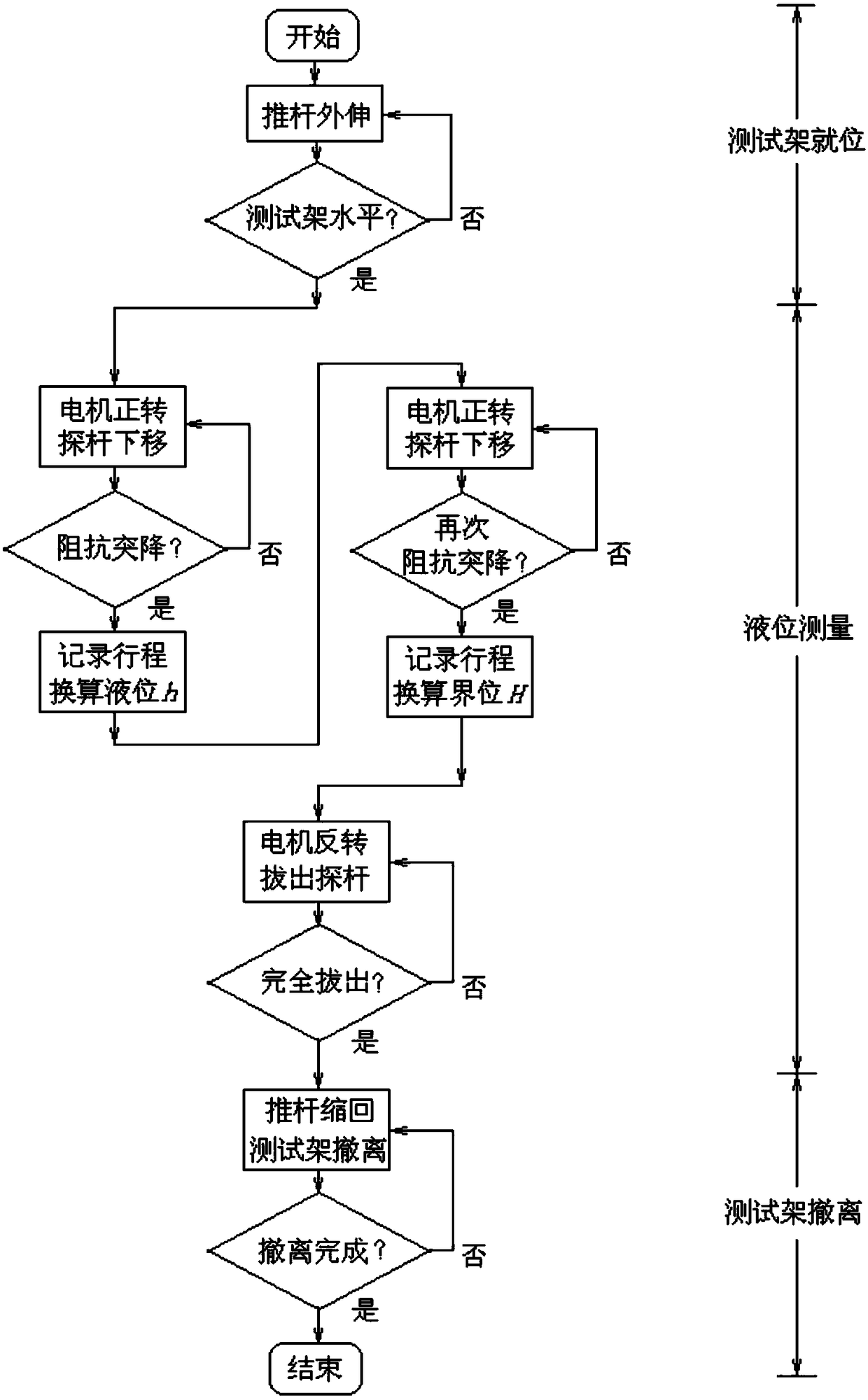

[0047] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

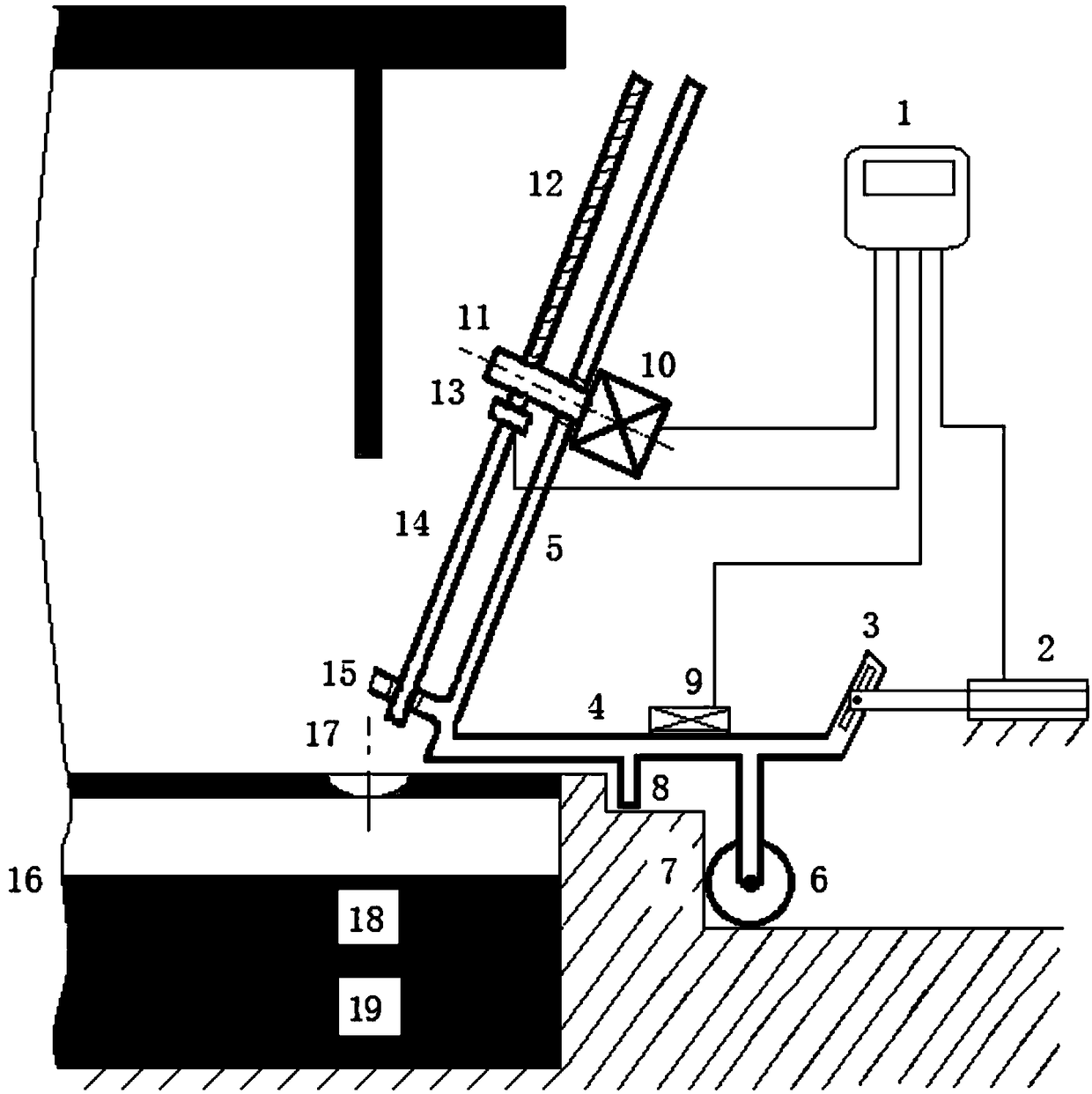

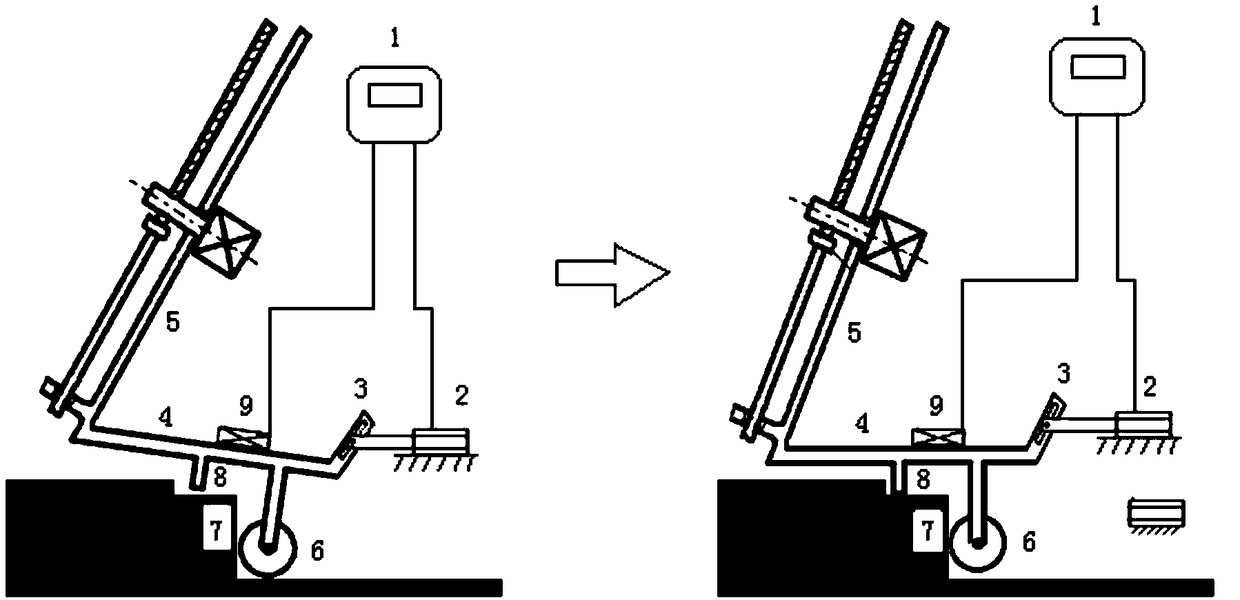

[0048] see figure 1 As shown, an on-line autonomous measurement system for electrolyzer liquid level based on impedance changes, including an angled test frame composed of a base plate 4 and a back plate 5, a push rod 2 and an electronic component 1; rollers 6 and U Type reference frame 8, the top of the base plate 4 is provided with an inclination sensor 9, and the right side of the base plate 4 is provided with a chute 3 that cooperates with the push rod 2; it also includes a motor 10 and an impedance probe rod 14, and the impedance probe rod 14 It is arranged in front of the backboard 5, and the motor 10 is arranged behind it, and the motor 10 drives the movement of the impedance probe rod 14; , motor 10, impedance probe rod 14 and push rod 2 are ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com