Piezoelectric sensor for monitoring internal unidirectional stress of component and application thereof

A piezoelectric sensor and unidirectional stress technology, applied in the field of stress sensors, can solve the problems of stress error, inconsistent state, inability to accurately measure the internal stress of components, etc., and achieve the effect of broad application prospects and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

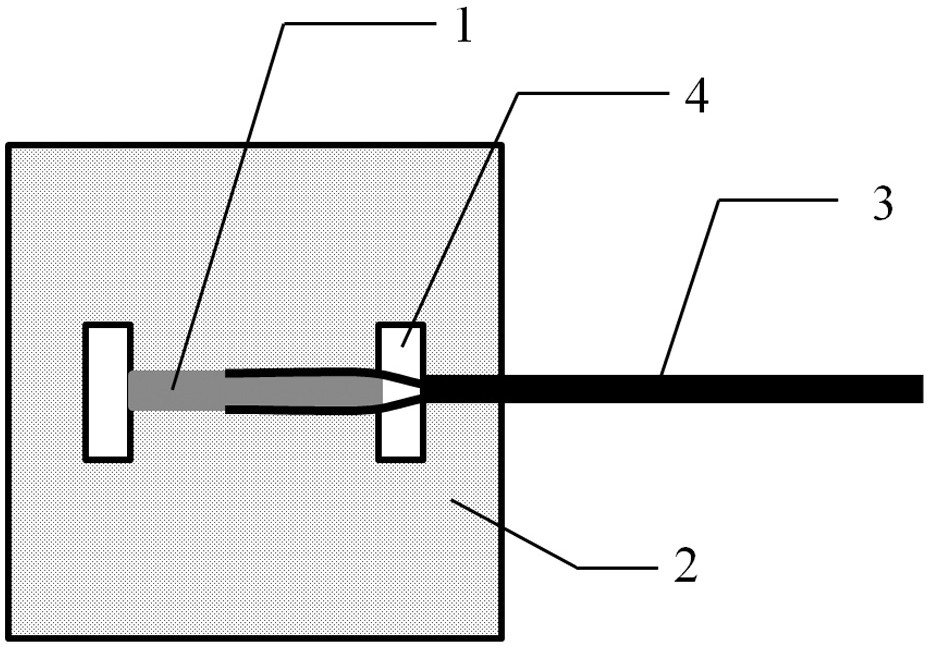

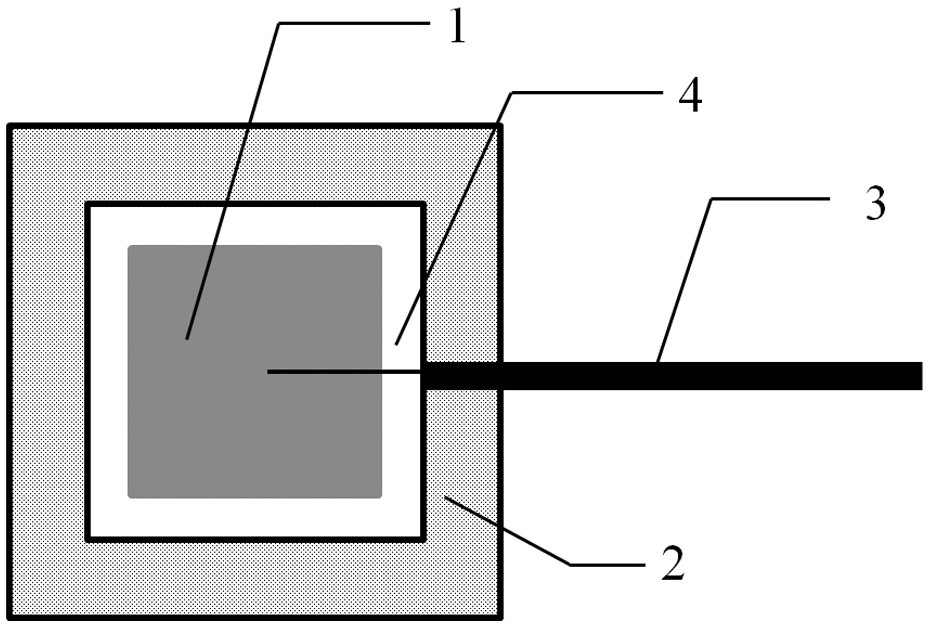

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] see Figure 1-3 , the present invention provides a piezoelectric sensor for monitoring the internal unidirectional stress of a component, comprising a mold body 2, a piezoelectric ceramic sheet 1 and a shielding wire 3, the inner core at the front end of the shielding wire 3 and the top and bottom of the piezoelectric ceramic sheet 1 The piezoelectric ceramic sheet 1 is embedded in the mold body 2, and the mold body 2 is provided with an annular groove 4 on the outer periphery of the piezoelectric ceramic sheet 1, so that the piezoelectric ceramic sheet 1 only has the upper and lower parts and the mold body 2 contact, but its surrounding parts are not in contact with the mold body 2, so the piezoelectric ceramic sheet 1 only bears force in one direction, and the front section of the shielding wire 3 and the inner core connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com