Cycloidal Pinwheel Transmission Based on Floating Needles and Its Modification Method

A technology of cycloidal pinwheel and transmission device, which is applied in the direction of gear transmission device, transmission device, hoisting device, etc. It can solve the problems of high dimensional accuracy, difficult processing, and complicated calculation of modification amount, so as to make up for gap defects , The modification method is simple and easy, and the effect of improving the bearing capacity and transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] A modification method of a cycloidal pinwheel transmission based on floating pin teeth, which is used for a cycloidal pinwheel transmission. The traditional cycloidal pinwheel transmission includes a housing, pin teeth and a swing gear. The modification method of the present invention It can keep all the needle teeth in the cycloidal pinwheel transmission in constant contact with the cycloidal gear, and can automatically eliminate the backlash caused by work wear, thereby improving the bearing capacity and transmission accuracy of the cycloidal pinwheel transmission.

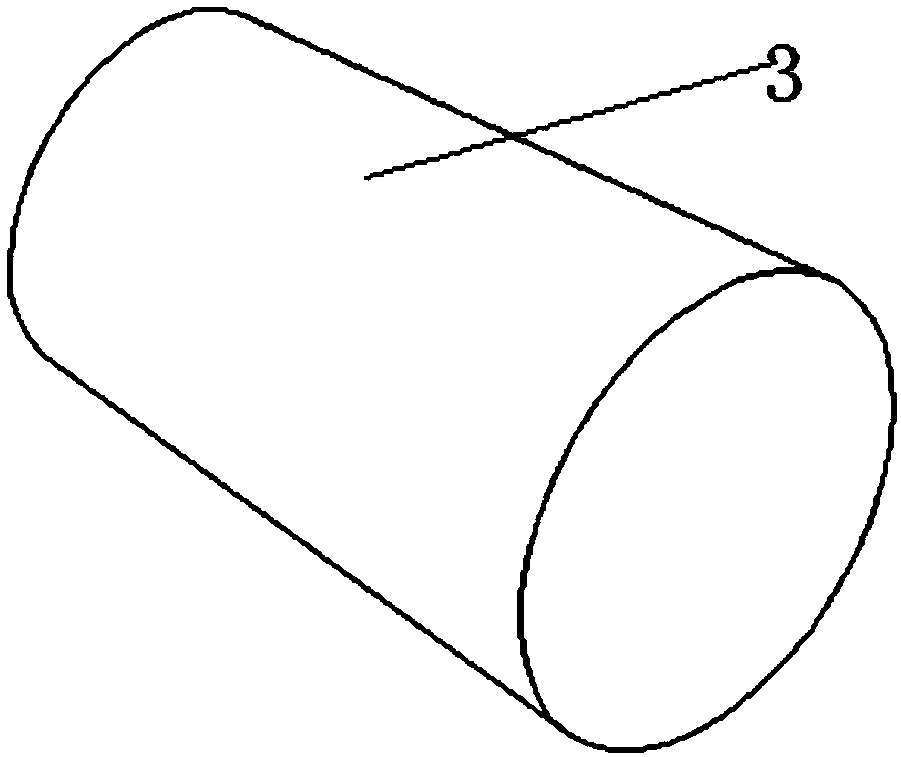

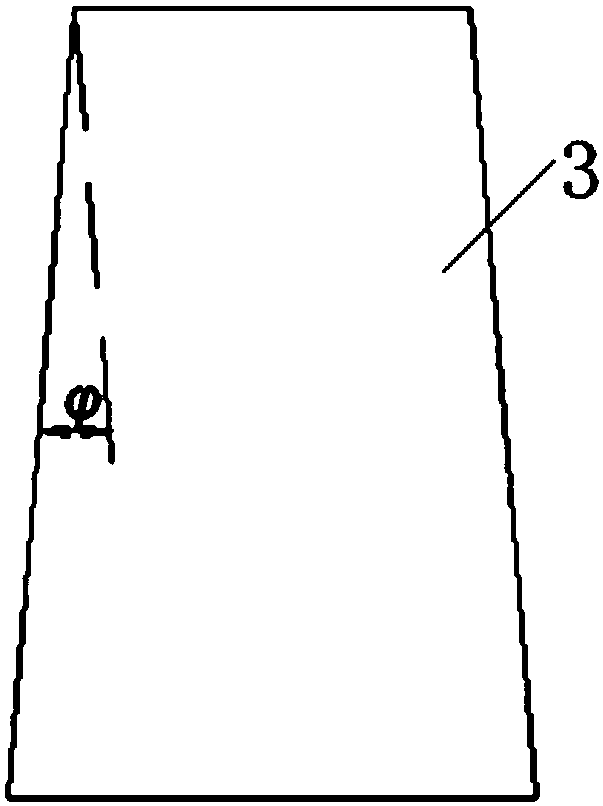

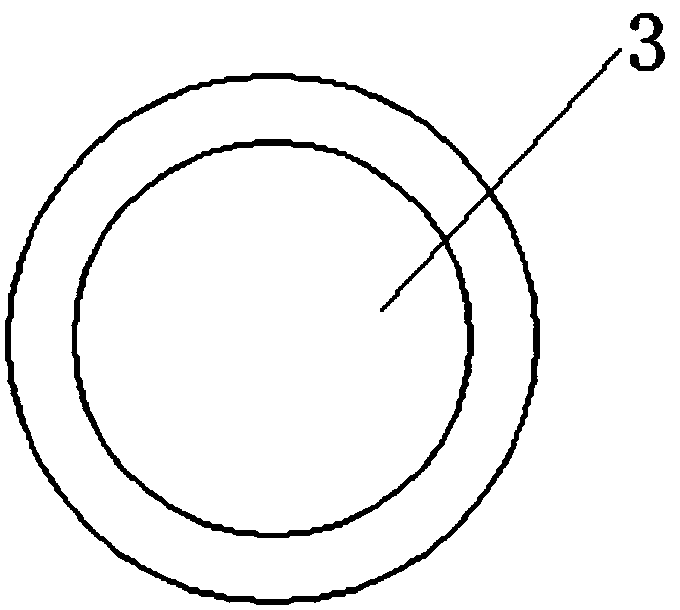

[0051] Change the cylindrical needle teeth in the traditional cycloidal pinwheel drive to the cone-shaped needle teeth, and equip the large end faces of each needle tooth with springs and end caps to fix the springs;

[0052] The side of the cycloidal gear in the traditional cycloidal pinwheel transmission is changed to a conical surface, so as to match the conical surface of the needle tooth. When modifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com