Composite connector for high-speed motor vehicle anti-yaw damper system

A shock absorber and composite technology, applied in the direction of shock absorbers, shock absorbers, motor vehicles, etc., can solve problems such as high joint stiffness, inability to meet the high elasticity requirements of anti-snaking shock absorbers, and rubber damage, etc., to achieve The cost is controllable, the large-scale application prospect is highlighted, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

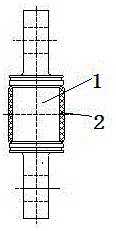

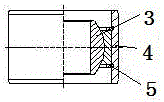

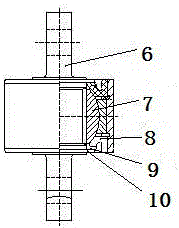

[0021] The composite joint for the anti-snaking shock absorber provided by the present invention, when the joint is subjected to the axial load of the shock absorber, the rigidity of the ball bearing is extremely high, and after the rubber is pressed into the ball bearing, the series rigidity of the two meets the rigidity of the joint of the vehicle Requirements: When the mounting rod twists or swings relative to the shock absorber, the ball head of the ball bearing slides relative to the ball bowl. Due to the extremely small resistance moment, the rotation has minimal impact on the rubber layer and the sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com