Reducer brake for crane

A technology of machine brakes and cranes, applied in the types of brakes, axial brakes, gear transmission mechanisms, etc., can solve problems such as the inability to achieve adjustable brake pressure, the large space for the axial size of the brake, and the inability to lock the brake with the opening pressure. , to achieve good dynamic and static sealing effect, simple structure, and the effect of ensuring braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

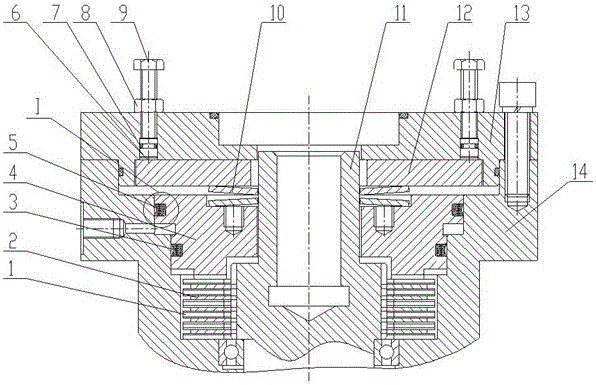

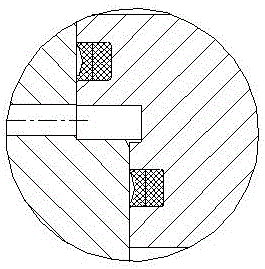

[0018] Such as figure 1 As shown, a reducer brake for a crane includes a friction static plate 1, a friction moving plate 2, a first combination seal 3, a piston 4, a second combination seal 5, multiple adjustment devices, a disc spring set 10, and a coupling 11. The pressure plate 12, the connecting plate 13 and the brake housing 14, the static friction plate 1 is located under the moving friction plate 2, the moving friction plate 2 is located under the piston 4, the static friction plate 1 and the The brake housing 14 is connected by an involute gear, the friction moving plate 2 and the coupling 11 are connected by an involute gear, and the first combined seal 3 and the second combined seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com