Scroll compressor assembly, manufacturing method thereof and scroll compressor

A technology of a scroll compressor and a manufacturing method, which is applied in the field of compressors, and can solve the problem of large energy consumption and sewage discharge in the treatment process, flaky coatings that affect the performance and reliability of the compressor, and failure to meet the long-term requirements of the scroll of the compressor. Wear resistance and other issues to achieve the effect of prolonging the service life of the equipment, reducing the friction coefficient, and preventing carbonization and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical means and functions adopted by the present invention to achieve the predetermined purpose, the specific implementation, structure, features and functions of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. In the following description, particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

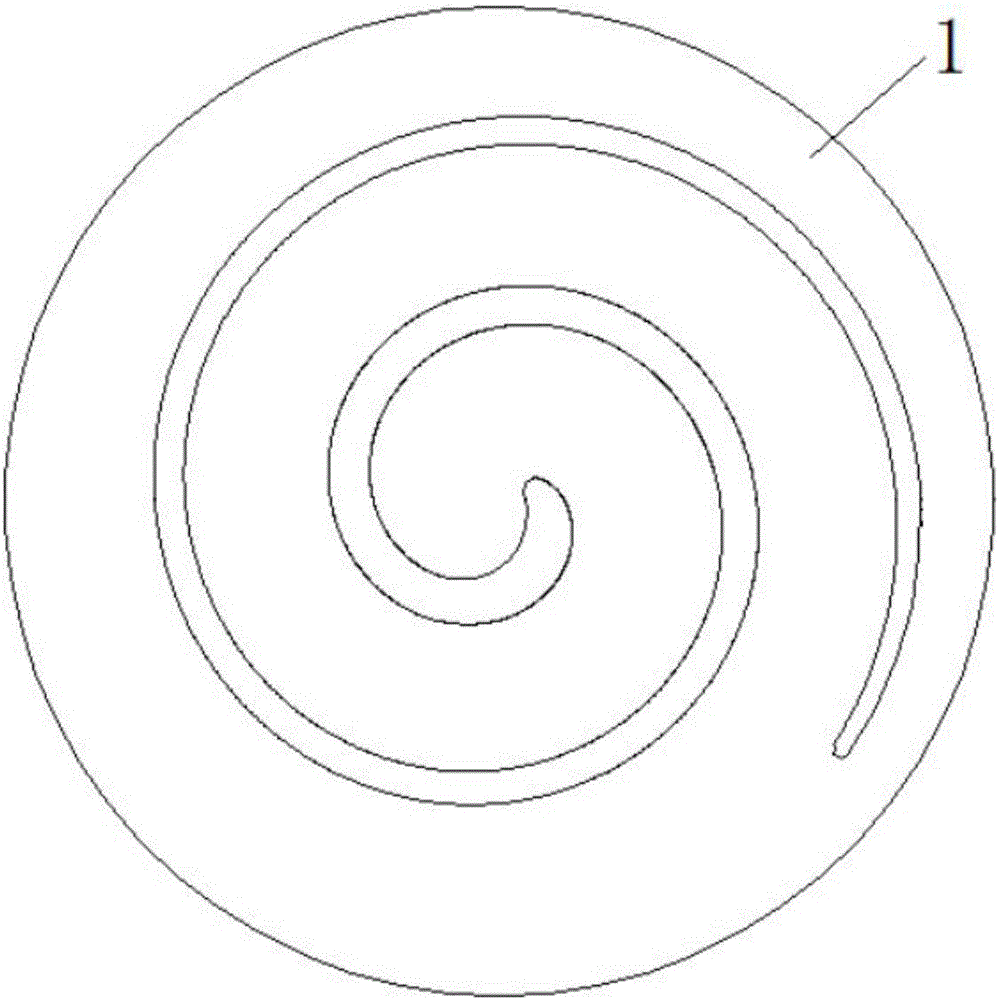

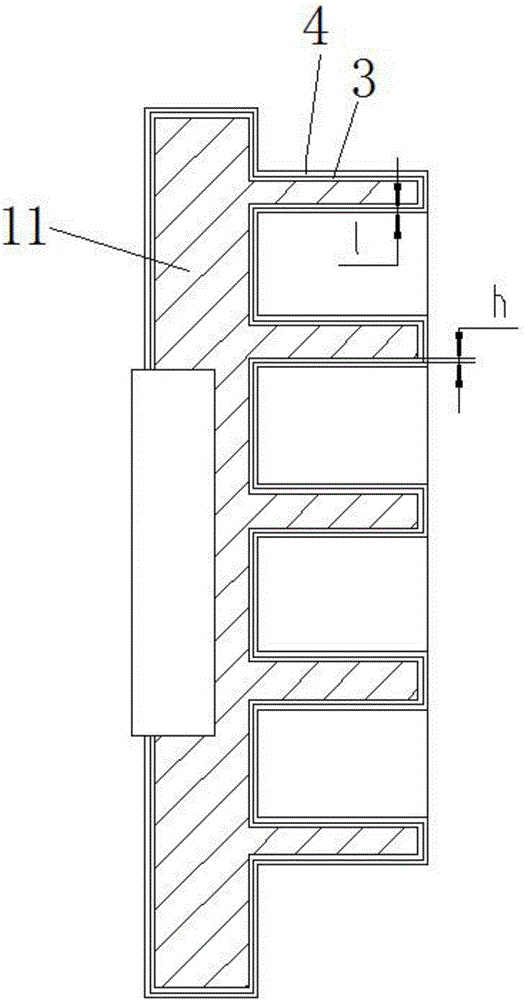

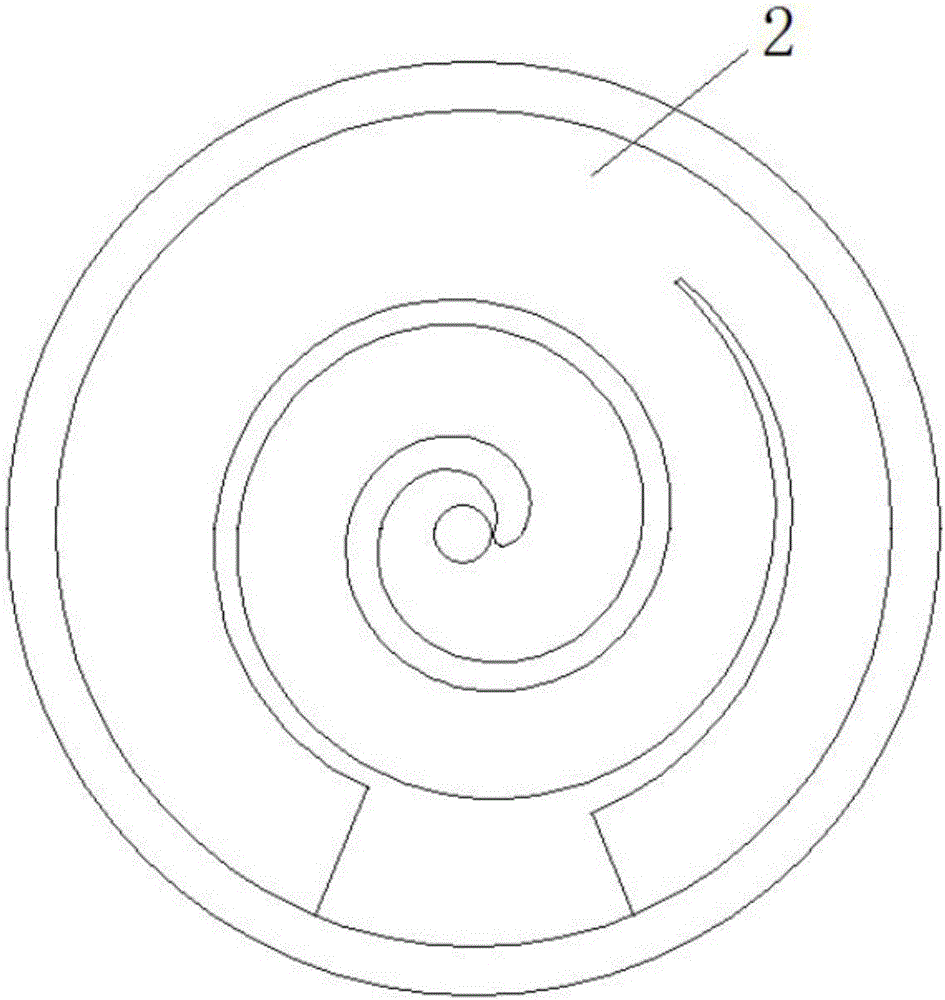

[0046] A scroll compressor assembly, comprising an orbiting scroll 1 (see figure 1 , figure 2 ) and fixed scroll 2 (see image 3 , Figure 4 );

[0047]Generally, for a common scroll compressor, the movable scroll 1 is a movable scroll, and the fixed scroll 2 is a fixed scroll. The movable scroll 1 and the fixed scroll 2 are arranged in cooperation to form a compression chamber between them. When the compressor is running, the movable scroll 1 is driven to move along...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com