A fixed-point multi-stage fracturing method for vertical wells and its application

A technology for fracturing and vertical wells, which is applied in earthwork drilling, wellbore/well components, production fluids, etc. It can solve the problems of complex drilling and grinding process, small construction displacement and high operation cost, and achieve the purpose of improving single well production and construction The effect of large displacement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

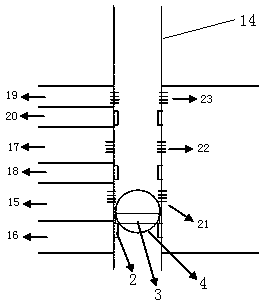

[0026] In order to solve the problems of low single well production after fracturing in the existing cluster perforation technology, small construction displacement in the intralayer layered fracturing technology, and bridge plug layered fracturing technology needs to drill and grind off the bridge after fracturing. plug, the drilling and grinding process is complicated, and the operation cost is relatively high. This embodiment provides the following figure 1 and figure 2 A fixed-point multi-stage fracturing method for vertical wells shown, comprising the following steps:

[0027] Step 1. After the vertical well drilling is completed, the reservoir address parameters are determined according to the logging data, and the reservoir is divided into multiple fracturing sections. Each fracturing section is composed of oil layers and sand-mud thin interbeds from top to bottom;

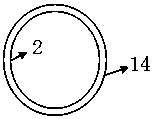

[0028] Step 2: Run the casing 14 equipped with the casing seat 2 into the well, ensure that a casing s...

Embodiment 2

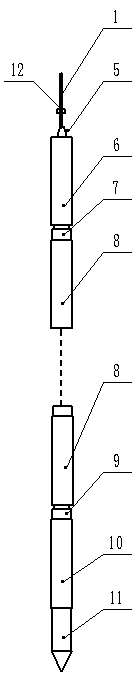

[0037] On the basis of Example 1, such as figure 2As shown, the perforating joint tool string consists of a bridle 5, a magnetic locator 6, a nozzle 7, a perforating gun 8, a gun tail 9, a setting tool 10, and an elastic ring delivery tool 11. The magnetic locator 6 is connected to the cable 1 through the bridle 5, and the torpedo 12 installed on the cable 1 is above the bridle 5.

[0038] The elastic ring 3 is crimped by a special tool and placed in the delivery tool. The delivery tool and the setting tool are threadedly connected, and the upper part of the setting tool 10 is threaded with the breech 9, mainly to seal the setting tool 10 and the perforating gun 8. The upper part of the perforating gun 8 is threadedly connected with the gun head 7. The magnetic locator 6 is mainly used to determine the precise position of the instrument after entering the well, so as to ensure the precise delivery of the elastic ring 3 and the perforation operation. The connection device, to...

Embodiment 3

[0040] On the basis of embodiment 1 or 2, such as Figure 5 As shown, the elastic ring delivery tool 11 is composed of a cylindrical part and a conical part connected from top to bottom. The outer diameter of the conical part is smaller than the inner diameter of the cylindrical part. Gunpowder and an elastic ring 3 are housed in the internal cavity of the gunpowder, and the elastic ring 3 is located below the gunpowder and is in a compressed state, coaxial with the cylinder.

[0041] Such as Figure 4 As shown, when the elastic ring 3 is in the elastic ring delivery tool 11, it is elastically compressed and the size is small ( Figure 4 left part), after the elastic ring 3 is dropped from the elastic ring delivery tool 11 to the casing seat 2, the elastic releases and the size becomes larger ( Figure 4 Right part), when the elastic ring 3 is released, it passes through the conical part, and then sits on the casing seat 2, and the elastic ring delivery tool 11 is finally li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com