A double-effect auxiliary heavy oil huff and puff development method for plugging regulation and drainage

A technology for heavy oil and oil layers, which is applied in the field of double-effect auxiliary heavy oil huff and puff development of plugging control and drainage, can solve the problems of large difference in the suction strength of each layer, steam overloading, pressure drop, etc., so as to improve the water recovery rate and increase the The effect of formation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

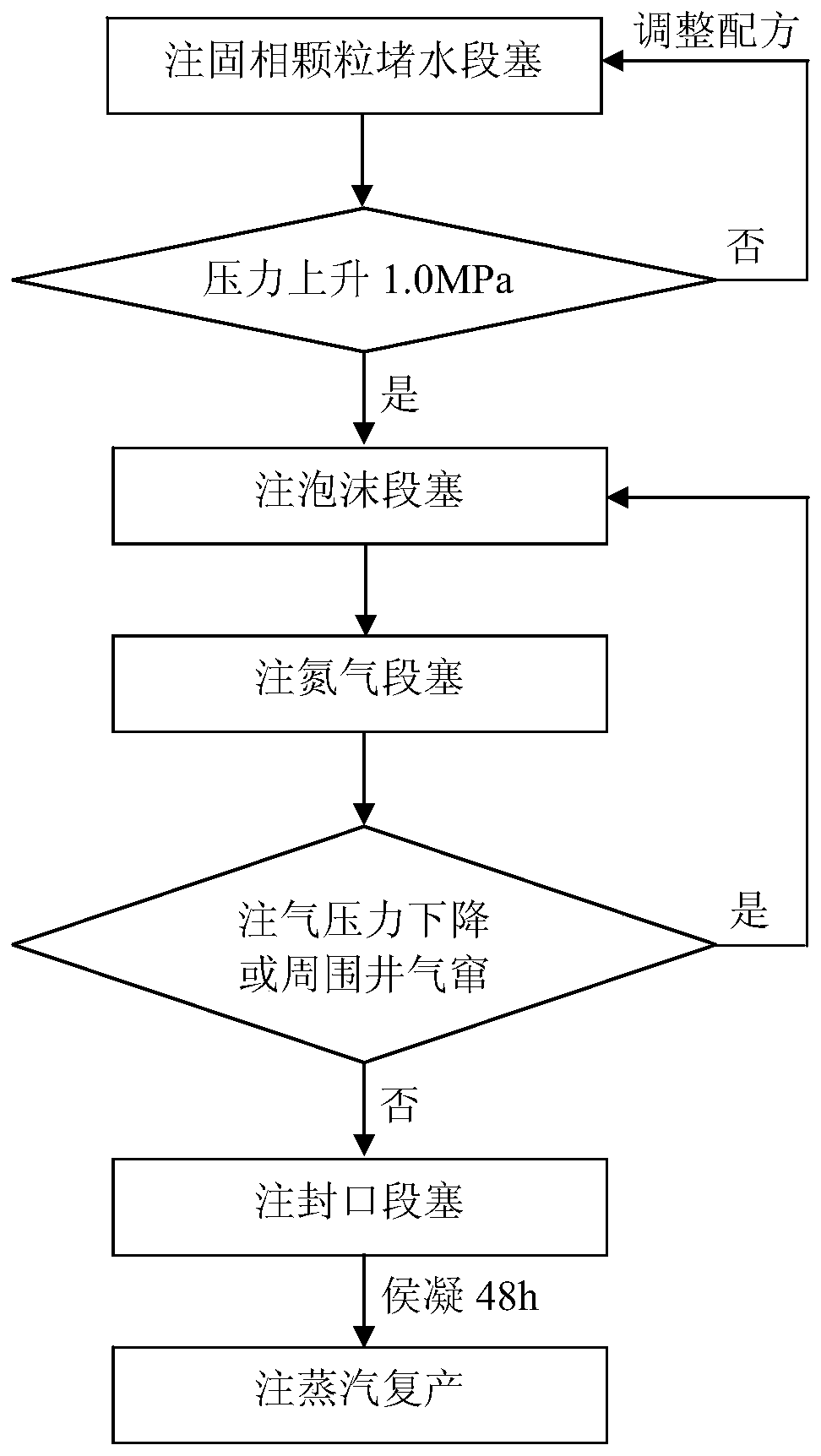

[0068] This embodiment provides a double-effect auxiliary heavy oil huff and puff development method for plugging regulation and drainage, which includes the following steps:

[0069] Well Wa 31-30 is a production well in Xiaowa Oilfield. The underground crude oil viscosity is 32000mPa.s. After 20 rounds of conventional steam huff and puff for oil production, the production cycle is shortened, the output drops significantly, and the formation pressure drops from 7.5MPa to 3.1MPa.

[0070] In July 2015, the oil well was constructed with the dual-effect auxiliary heavy oil huff and puff technology provided in this example, so solid-phase particle water plugging slugs were injected 200m 3 , in this solid phase particle water blocking slug, calculate with the total volume of this solid phase particle water blocking slug, the mass concentration of lignin particle is 0.5%, the mass concentration of polymer (anionic polyacrylamide) is 0.2% , wherein the lignin particles are composed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com