Adjustable haunch angle forming mould plate

A forming formwork, adjustable technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of unadjustable, explosive mold and waste of axillary forming formwork, and achieve structural Sturdy, high turnover rate, less waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

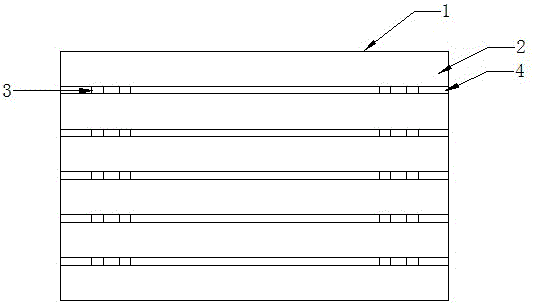

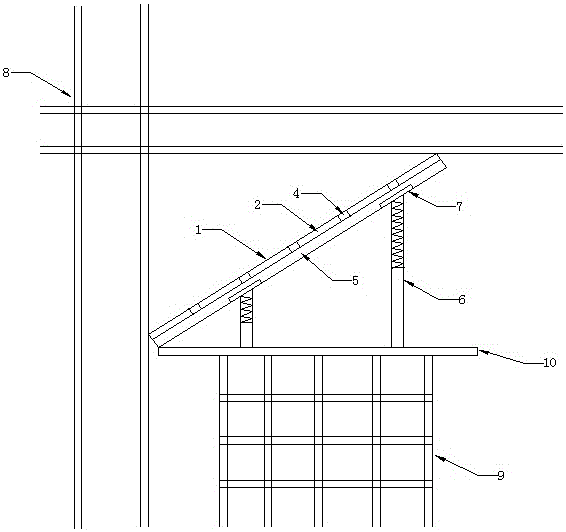

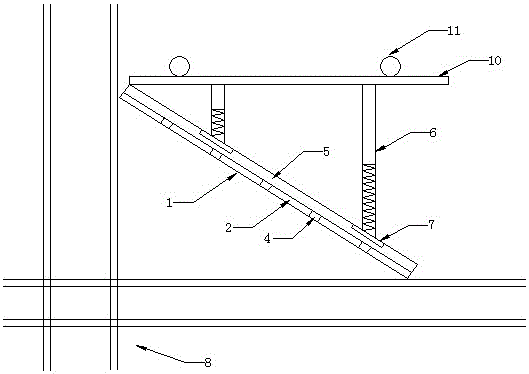

[0022] Such as figure 1 As shown, it is an embodiment of an adjustable axillary angle forming template of the present invention, including a rollable steel plate 1 and a fixed rod 5; the rollable steel plate 1 includes several strip steel plates 2, and the long sides of the strip steel plates 2 Aligned and arranged vertically, a hinge mechanism 3 is provided between two adjacent strip steel plates 2, and the gap between two adjacent strip steel plates 2 is sealed with elastic material 4, and the rollable steel plate 1 can be rolled up and unfolded To adjust the total width to keep the axillary corners tightly closed; there are several fixed rods 5, which are overlapped in parallel on the outside of the rollable steel plate 1, and the rollable steel plate 1 is fixed on the main support structure 8 through several fixed rods 5 , formin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com