Method for building fill dams in red mud disposal site through slurry dry method and structure of fill dam

A technology for stacking dams and red mud, applied in the field of red mud storage, can solve the problems of difficult dam building, easy accumulation of water, long dam building time, etc., and achieve the effect of improving the stability of the dam body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

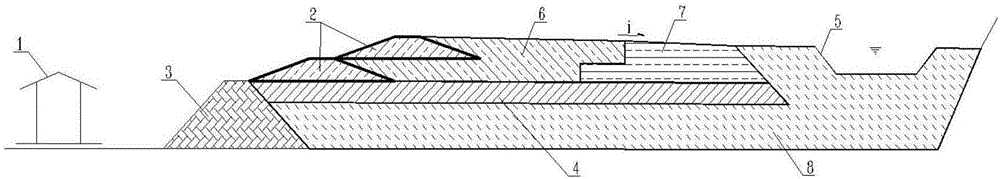

[0016] Such as figure 1 As shown, the structure of the accumulation dam of the slurry dry process red mud storage yard of the present invention is as follows, including the initial dam 3 of the slurry red mud storage yard, and the inner side of the initial dam 3 is provided with an accumulation dam filled with filter cake red mud 2. On the outside of the initial dam 3, there is a red mud filter cake press workshop 1 for producing filter cake red mud, and on the inside of the initial dam 3 and the dry red mud filter cake storage area 7, there is a slurry red mud discharge area 8; 3 On the slurry red mud discharge area 8 within the dry beach area in front of the dam, there is a foundation 4 constructed of block stones or filter cake red mud, and on the foundation 4 there is an accumulation dam constructed of filter cake red mud 2. Inside the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com