Sinking vertical lifting gate

A vertical lift and gate technology, applied in the field of gates, can solve the problems of large capacity of hydraulic hoists, water blocking of the gate body, increased load, etc., so as to improve reliability and safety, avoid water blocking and garbage jam, and reduce installation. the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

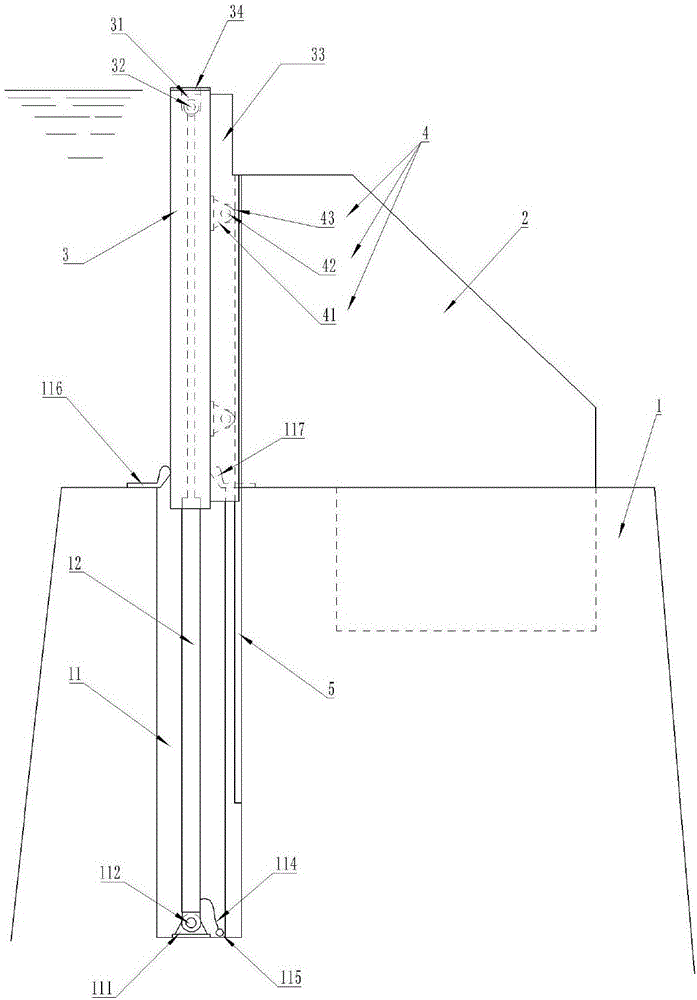

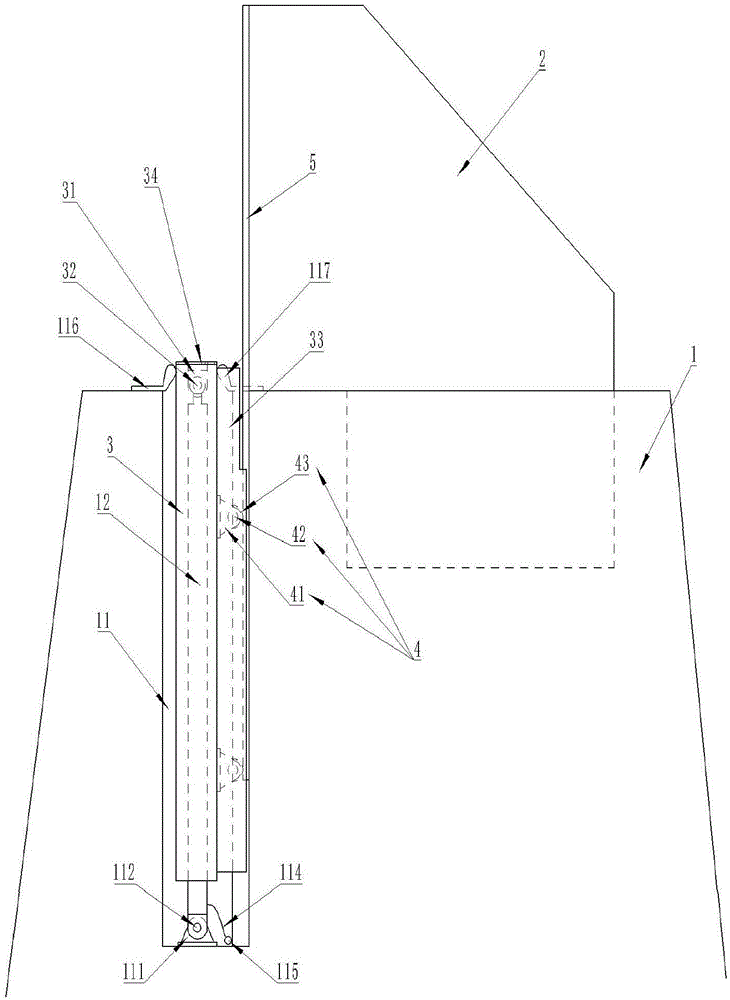

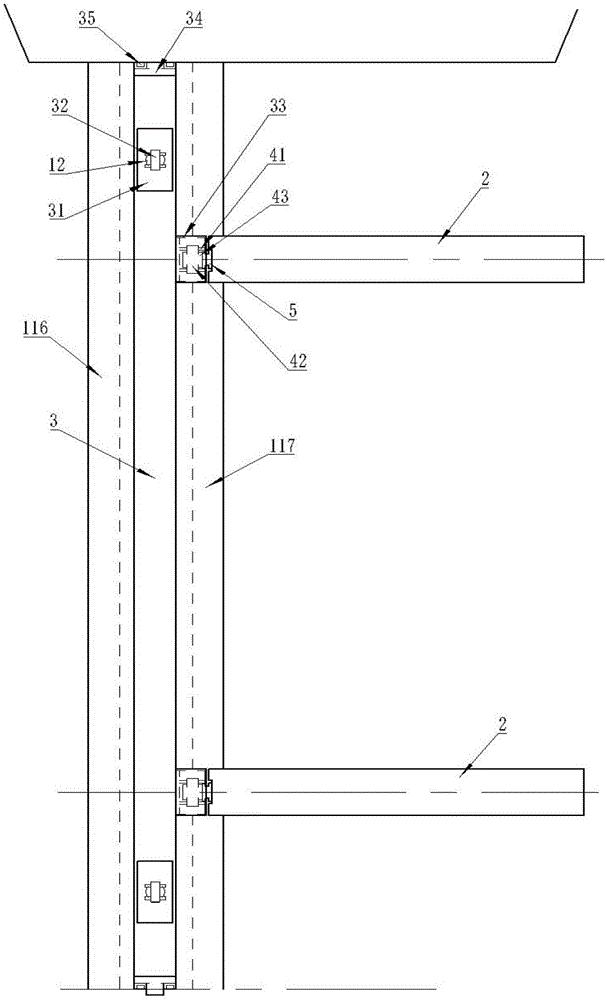

[0024] like figure 1 , figure 2 and image 3 As shown, a sunken vertical lift gate includes a dam body 1 on the river channel, two buttresses 2 are fixedly arranged on the weir dam body 1, and a gate leaf 3 is installed on the front edge of the buttress 2, and the two A door slot 11 is arranged on the weir dam body 1 facing the water of each pier 2, and two fixed oil cylinder seats 111 are installed on the bottom of the door slot 11 below each door leaf 3, and oil cylinder shafts are installed on the fixed oil cylinder seats 111. One 112; a movable cylinder seat 31 is arranged on the inner wall of the upper end surface of the door leaf 3 at the vertical corresponding position to the fixed oil cylinder seat 111, and the movable oil cylinder seat 31 is connected with the oil cylinder shaft 2 32, and the oil cylinder shaft 2 32 and the oil cylinder shaft 112 pass through the hydraulic cylinder 12 The hydraulic cylinder 12 is connected to the external hydraulic control system t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com