Steel corrugated pipe infrastructure

A basic structure and corrugated pipe technology, applied in the field of basic structure, can solve the problems that the circular section should not be fixed in the position to be placed, the large-diameter assembled structure is difficult to fix its position, and the wedge-shaped part cannot be mechanically compacted, etc., so as to shorten the construction period. Period, strong structural deformation, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in combination with specific embodiments.

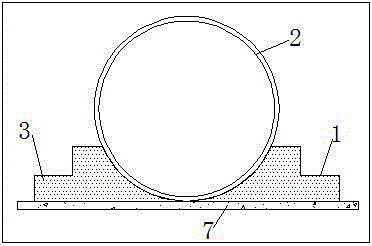

[0023] The invention relates to a steel corrugated pipe foundation structure, which includes a foundation shell 1 of geosynthetic material, and the inside is a cavity structure. One side of the basic shell 1 is provided with a groove for placing the steel bellows 2 , and the other side is provided with protruding steps to increase the grounding area and better prevent the steel bellows 2 from moving. Filling 3 is poured into the foundation shell 1, and the filling 3 conforms to the local geological environment, has good flexibility and rigidity, and can better adapt to deformation.

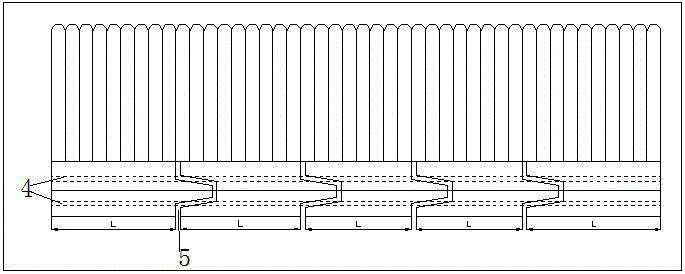

[0024] The foundation shell 1 is reserved with a reserved channel 4 for passing steel bars or anchor cables, and at the same time, it is fixed at both ends of the foundation, which can increase the integrity of the foundation and make the foundation more firm.

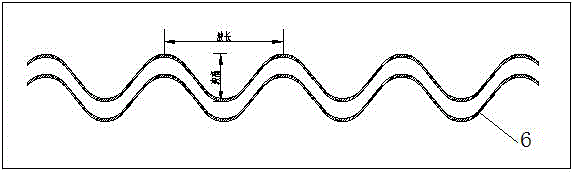

[0025] The basic shell 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com