A clamping device for semiconductor welding inspection

A welding detection and clamping device technology, applied in workpiece clamping devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve problems such as failure of electronic products, affecting packaging reliability, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

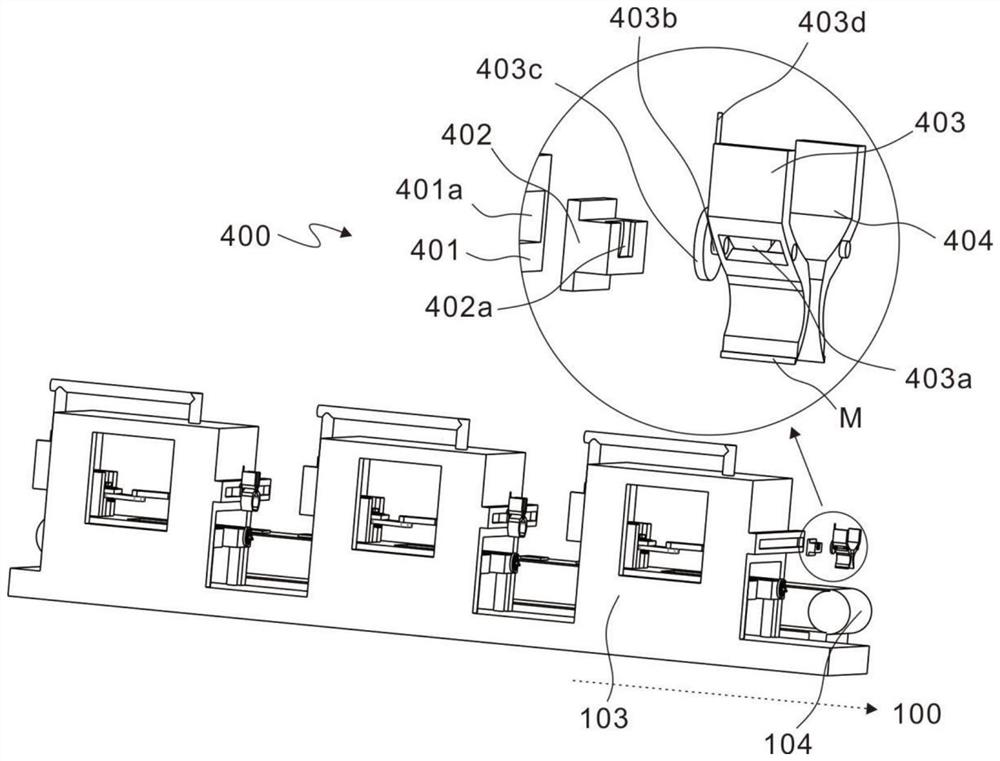

[0027] refer to figure 1 , 2 , which is the first embodiment of the present invention. This embodiment provides a semiconductor welding detection and clamping device, which includes a processing unit 100 and a clamping unit 400 .

[0028] The processing unit 100 includes an operation room 103 and a conveying belt 104. A plurality of operation rooms 103 are arranged in parallel, the conveying belt 104 is arranged on one side of the operation room 103, and the clamping unit 400 is installed on each operation room 103; in the operation room 103 The semiconductor chips are welded or inspected, and then sent to the conveyor belt 104 by the clamping unit 400. All the operation rooms 103 are arranged side by side on one side of the conveyor belt 104 to form an industrial line, which has fast processing efficiency and convenient transportation.

[0029] Further, the clamping unit 400 includes a sliding rail 401, a second sliding block 402, a first clamping member 403 and a second cla...

Embodiment 2

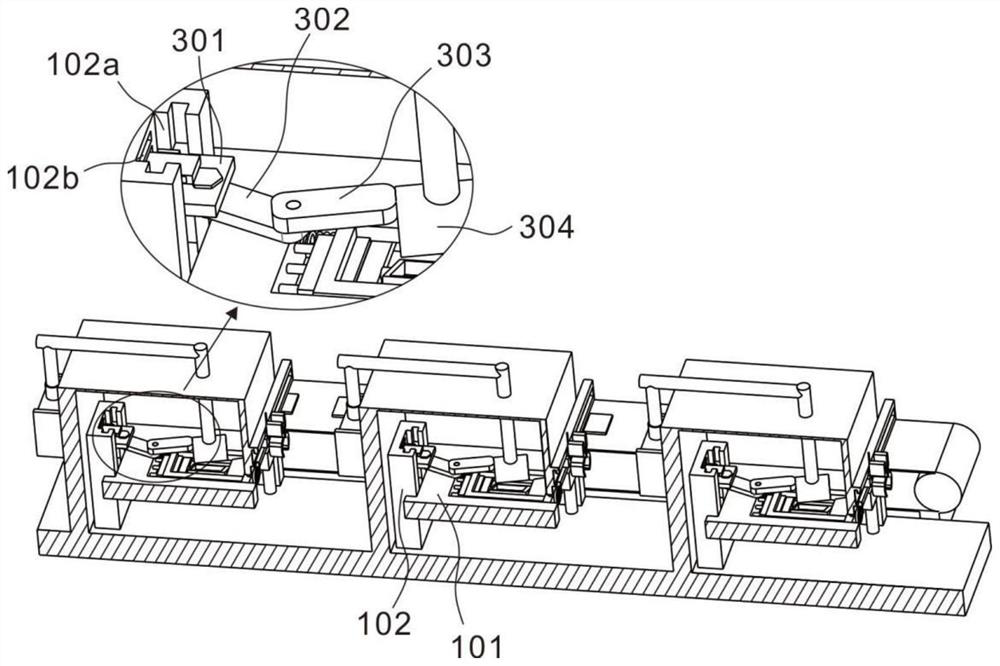

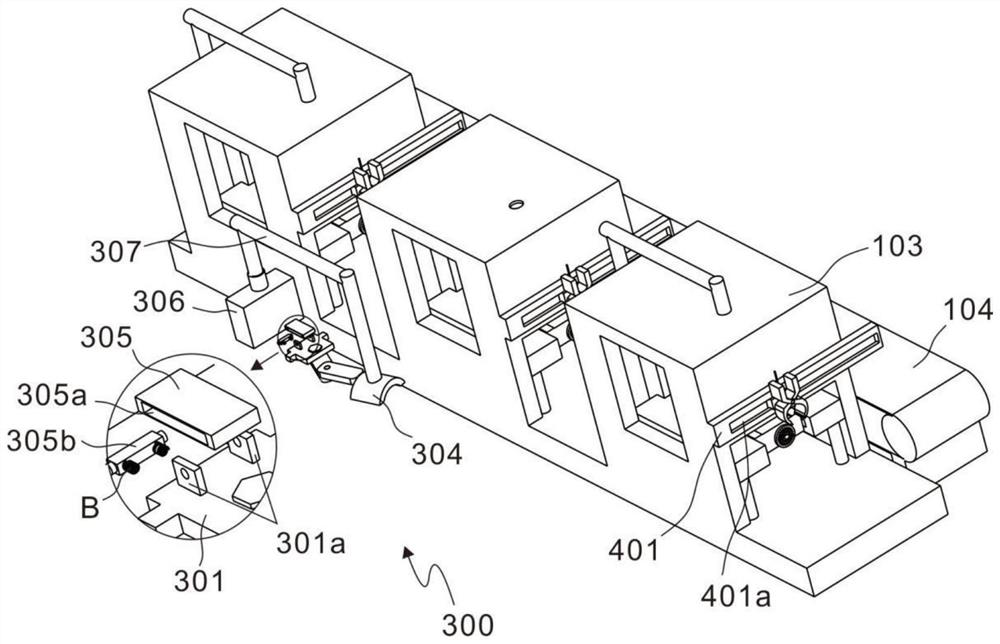

[0035] refer to Figures 2 to 5 , is the second embodiment of the present invention, which is based on the previous embodiment and further includes a dust removal unit 300, which is movably arranged on the adjustment table 102 and faces the platform 101 at the bottom for absorbing the smoke and dust generated by welding and discharged from the operating room 103 .

[0036] The dust removal unit 300 includes a moving plate 301, a turning plate 302, a hinge plate 303 and a dust collector 304. Specifically, the dust removal unit 300 is located above the platform 101 and is connected to the adjusting table 102. The moving plate 301 is movably arranged on the adjusting table 102, and the turning plate 302 One end is bolted to the moving plate 301 , the other end is hinged to the hinge plate 303 , and the other end of the hinge plate 303 is connected to the dust collector 304 .

[0037] Further, a T-shaped groove 102a is vertically disposed on the adjustment table 102, and the T-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com