Method and device for preparing chopped fiber continuous orientation felt

A chopped fiber and orientation technology, applied in the field of fiber fabric materials, can solve the problems of inability to continuously and efficiently prepare chopped fiber orientation mats on a large scale, and achieve high controllability of width, length and fiber content, high degree of automation, The effect of energy saving and environmental protection of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

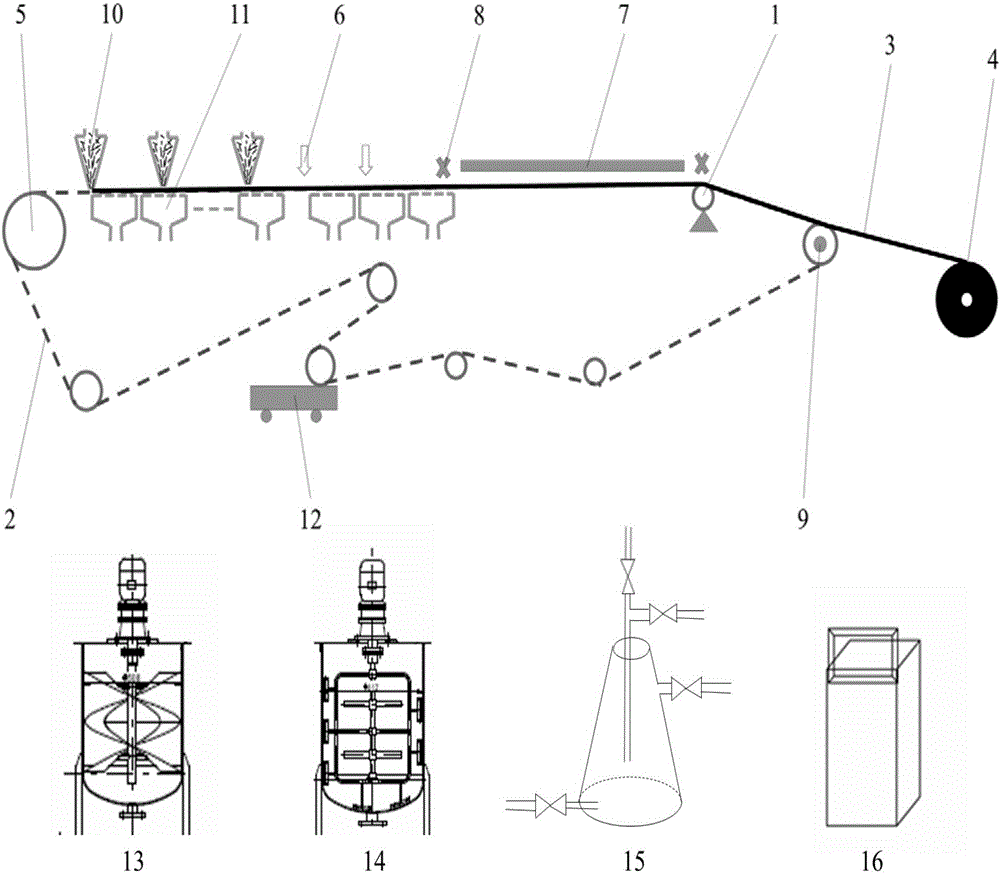

Method used

Image

Examples

Embodiment 1

[0037] Dispersion: first add 40L of water to the dispersing device, weigh 250g of hydroxyethyl cellulose and add it to the dispersing device (13), start the stirring and dispersing device, the dispersing time is 20min, and the stirring speed is 200r / min; then weigh the chopped carbon fiber (Toray company T700 chopped carbon fiber, fiber length is 4mm) 160g is added in the dispersing device, and the stirring speed is increased to 500r / min, and the dispersion time is 5min, and the chopped carbon fiber suspension with good dispersibility is obtained and added to the stirring tank. (14) in the feeding device, now the viscosity of the fiber suspension is 0.8Pa.s; the dispersion work continues in the process of preparing the T700 chopped carbon fiber continuous orientation mat, to supplement the consumption of the fiber suspension in the storage device;

[0038] Orientation: The chopped fiber suspension dispersed in the storage device is introduced into the tapered orientation nozzle...

Embodiment 2

[0044] Dispersion: first add 40L of water to the dispersing device, weigh 200g of hydroxypropyl cellulose and add it to the dispersing device (13), start the stirring and dispersing device, the dispersing time is 30min, and the stirring speed is 300r / min; then weigh the chopped glass Add 150g of fiber (fiber length: 10mm) into the dispersing device, increase the stirring speed to 800r / min, and disperse for 10 minutes to obtain a well-dispersed chopped glass fiber suspension and add it to the stirring storage device (14) , the viscosity of the fiber suspension at this time is 1.2Pa.s;, the dispersion work continues in the process of preparing the chopped glass fiber continuous orientation mat, to supplement the consumption of the fiber suspension in the storage device;

[0045] Orientation: The dispersed chopped glass fiber suspension in the storage device is introduced into the tapered orientation nozzle, and then flattened on the continuously running conveyor belt after passin...

Embodiment 3

[0051] Dispersion: first add 40L of water to the dispersing device, weigh 400g of hydroxyethyl cellulose and add it to the dispersing device (13), start the stirring and dispersing device, the dispersing time is 30min, and the stirring speed is 400r / min; then weigh the chopped carbon fiber (Fiber length is 15mm) 100g is added in the dispersing device, and the stirring speed is increased to 1000r / min, and the dispersing time is 20min, and the chopped carbon fiber suspension with good dispersibility is added to the stirring storage device (14). When the viscosity of the fiber suspension was 2.4Pa.s; the dispersion work continued in the process of preparing the chopped carbon fiber continuous orientation mat to supplement the consumption of the fiber suspension in the storage device;

[0052] Orientation: The chopped carbon fiber suspension dispersed in the storage device is introduced into the tapered orientation nozzle, and spread on the continuously running conveyor belt after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com